The Problem is in the Mirror: A Live Chat on the Future of Direct Procurement

View highlighted excerpts from the EBN live chat on The Future of Direct Procurement, along with Pierre Mitchell, chief research officer at Spend Matters, and host Hailey Lynn McKeefry, managing editor of EBNOnline.

In September 1983, the Harvard Business Review published a groundbreaking article by Peter Kraljic on purchasing strategy that is widely cited today as the beginning of the transformation of the function from “purchasing” to something viewed as highly tactical to procurement or supply management – as well as very strategic to the business.

Fast-forward to today’s practice, and consider this question posed by the Spend Matters/ISM study: Has procurement become a truly strategic supply management transformation agent that helps lead the redesign and orchestration of multi-tier supply beyond its primary role as negotiator, cost cutter, contract manager, etc.?

“Unfortunately, in the supply chain, the answer is generally no,” answers one of the study’s authors, Pierre Mitchell, Chief Research Officer for Spend Matters.

Among the study’s findings:

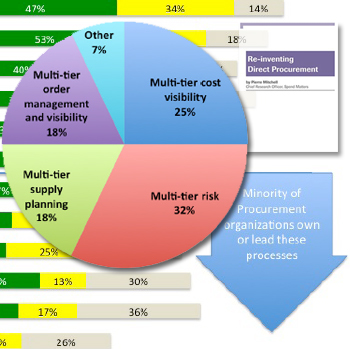

A high procurement “quantity of spend management influence” during sourcing does not imply a high “quality of supply management influence” across the end-to-end supply chain. Although a slight majority of procurement organizations own the sourcing process, a minority of firms could say the same in over a dozen other key process areas. The bottom line: Beyond sourcing, procurement has a relatively low level of influence and responsibility for broader supply management processes. Few firms allow procurement to drive key processes, such as strategic third-party management/innovation and inventory/supply planning.

For top performers where direct procurement had moved beyond sourcing to the kind of strategic supply management that Kraljic envisioned, the connectedness of procurement to other groups and suppliers was what made a difference. Almost a third of the “top capability” firms adopted a supply chain strategy/CoE (Center of Excellence) group that drove improvements across procurement, operations, logistics, quality, engineering, and more, compared to only 6 percent of their peers. Pace-setters aggressively pursue all paths to transformation, not just purchasing-centric methodologies. They take projects/priorities and approaches adopted from anywhere (e.g., supply chain network design, Lean/6 Sigma, sustainability, B2B information networks), if they have the potential to unlock value. This is where supply chain COE prove useful – not just in best practices benchmarking and transformation planning, but also in ensuring proper governance structures are in place and measurement systems are aligned from supply chain performance, even down to a purchased SKU level.

- Supply performance management and supply risk management are hampered by poor IT support. We suspect the IT challenge Kralijic is referring to is one faced by most companies that have attempted to extend enterprise-centric connectivity and collaboration solutions outward into their supply chain. All true collaboration tools require suppliers to be “on-boarded” to exchange data. This is especially true if the collaboration solution is meant to operate bi-directionally, meaning the supplier can respond to a request with a counterproposal instead of just a binary “yes/no” answer. This requires not only data exchange methods such as electronic data interchange (EDI) integration, but also role-based authentication of each specific trading partner, so they see only their portion of the supply chain. IT is generally understaffed and often lack the expertise to widely scale trading partner connectivity into a supply chain process, especially if it operates in the cloud. In a future post, we’ll discuss why supplier portals fail to make this grade.

The Spend Matters/ISM study assumed that organizations had already performed some level of strategic sourcing in terms of analyzing spend and rationalizing their supply base. Some of the capabilities evaluated did support strategic sourcing (e.g., cost modeling), but also went beyond it (e.g., using supplier collaboration for joint cost takedown projects).

Eleven capabilities were studied, which were grouped into four main categories:

Guiding and ensuring supply performance

Design for supply

Designing the supply network

- Planning and executing supply against demand within the network

While the scope and detail of the study cannot be covered in one post, it is important to note that the authors find the results illustrate “the vast opportunity available to direct procurement organizations and broader supply chain organizations seeking to capture [the] larger prize associated with optimizing the multi-tier supply network.”

This is an important study with significant implications for direct procurement, as well as how organizations should be thinking about the function in today’s marketplace.

Let us know (Fill in the form on the right hand side) how these findings compare to how direct procurement is measured in your organization.

Article Topics

E2open News & Resources

E2open President and CEO Farlekas Provides Logistics Trends and Themes Overview E2open Transportation Management Solution to Simplify Your Logistics Supply Chain Disruptions and the Next Normal for Logistics in 2023 Outsourced Quality and Sustainable Manufacturing in a World of Disruption Mitigating Supply Chain Disruption in the Wake of Severe Weather and Disasters Uber Freight & E2open to Provide Real-time Transportation Rate and Capacity Options Tracking and Reducing Transportation Emissions More E2openLatest in Supply Chain

Trucking Industry Pushes Back on Government’s Electric Mandates Senators Take Aim at Amazon with Warehouse Worker Protection Act Maersk Sees Silver Lining in Red Sea Shipping Challenges Happy Returns Partners With Shein and Forever 21 to Simplify Returns Baltimore Opens 45-Foot Deep Channel Following Bridge Collapse El Paso Border Delays Cost Juarez $32 Million Per Day in Economic Losses Ranking the World’s 10 Biggest Supply Chains More Supply Chain