The Extent that e-Commerce Impacts Fulfillment Operations

The relentless march of e-commerce continues to put tremendous strain on distribution and fulfillment operations.

To understand how companies are managing their e-commerce platforms under the weight of this pressure, Honeywell Intelligrated, in collaboration with Modern Materials Handling and the Peerless Research Group, surveyed 171 U.S.-based material handling executives.

The effort culminated in a recently published report, The Impacts of e-Commerce, Fulfillment Challenges and Improvement Priorities.

As expected, the survey results revealed that the majority of MHE executives are actively seeking solutions to combat rapidly escalating fulfillment complexities and new tools to manage mission-critical challenges, such as: labor management; order processing and tracking; and warehouse and distribution costs.

Yet, despite these known issues, many remain slow to adopt the technologies and automation needed to keep pace with increasing demands.

Grasping the extent of e-commerce impacts on DC operations will take time, so we’ll start by summarizing some of the key research findings.

Top order management, fulfilment and distribution challenges

Thirty-five percent of MHE executives reported that fulfilling more orders (faster and at lower costs) was their primary challenge. Reducing errors in order processing/improving order accuracy (28 percent) and obtaining enough labor to support operations (25 percent) were their second and third concerns, respectively.

Constraints to operational efficiencies

Not having sufficient workforce to handle e-commerce volumes and lack of available floor space were the top two constraints to operational efficiencies, at 46 percent and 40 percent, respectively. Difficulties adapting inventory workflow on the warehouse floor was cited by 38 percent.

How organizations are responding to growth

DC managers stated that addressing these challenges will require changes to their current facilities. Deploying more automated systems (44 percent) and adding manpower to their current labor force (37 percent) are their top two growth initiatives. Thirty-three percent reported that employing process improvement strategies and expanding the footprints of current facilities are also planned.

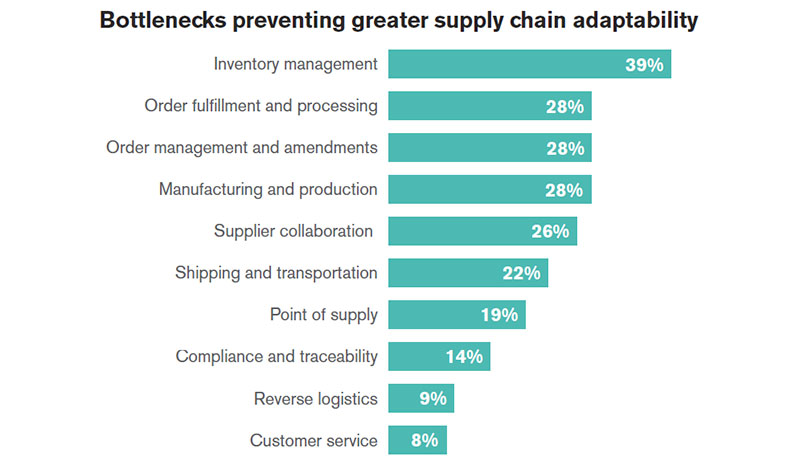

Bottlenecks preventing greater adaptability

The survey group cited inventory management (39 percent) bottlenecks are the most likely deterrents to supply chain adaptability. Order processing, management and amendments, production challenges and delays brought on by suppliers are also common culprits.

Aspects of fulfillment operations needing improvement

When identifying functional areas ripe for improvements, managers listed many phases of the fulfillment process, including: inventory management (46 percent), order picking (35 percent), order waving/releasing (28 percent) and packing (20 percent).

Level of automation in supply chain tasks

Even with the awareness of their known operational limitations, many organizations remain slow to automate. While the majority of respondents expressed the criticality of controlling freight/transportation and labor costs (79 percent and 75 percent, respectively), fewer than one in 10 companies has implemented automated labor management processes.

Furthermore, nearly one out of five assert they have no plans to implement labor management technology. Order management, invoicing and shipping visibility are the processes most likely to be automated, although the majority still only rely on partial automation methods.

Areas in which companies are/will be investing

In lieu of the absence of end-to-end automation across fulfillment operations, it was no surprise to learn that the majority of companies in our survey expect to increase investments in software (58 percent), such as WMS, WCS and WES. Labor management, facility expansion, packaging equipment and materials, and implementing or upgrading automated materials handling systems are also prime areas for upgrades.

It’s probably safe to assume that the majority of you reading this blog (and research report) are relating to the report’s findings. In a follow-up to this blog, we’ll look at some of the ways Honeywell Intelligrated can address these issues.

Related White Papers

The Impacts of e-Commerce: Fulfillment Challenges and Improvement Priorities

As labor shortages, costs and productivity challenges persist, many operators are introducing increasing levels of automation to meet online order volumes. Download Now!

Article Topics

Honeywell Intelligrated News & Resources

Southern Glazer’s Wine & Spirits: Proof positive innovation Southern Glazer’s Wine & Spirits: Proof positive innovation Time to integrate those robots Empower Your Automation Journey at ProMat 2023 Conveyors and sorters surge ahead Raise Your Operational Intelligence Report: Automation “a Matter of Survival” More Honeywell IntelligratedLatest in Warehouse|DC

European Parliament Passes New Law Requiring Supply Chain Accountability Talking Supply Chain: Understanding the FTC’s ban on noncompetes North Carolina Welcomes Amazon’s Newest Mega-Warehouse SAP Unveils New AI-Driven Supply Chain Innovations U.S. Manufacturing is Growing but Employment Not Keeping Pace Maximize Warehouse Space with Mezzanine Automation: Expert Tips Most Companies Unprepared For Supply Chain Emergency More Warehouse|DC