Transforming Supply Chain Operations to Deliver Perfect Orders

Genpact’s Lean Digital approach and One Network’s cloud platform drive automation and end-to-end supply chain visibility that generate customer delight.

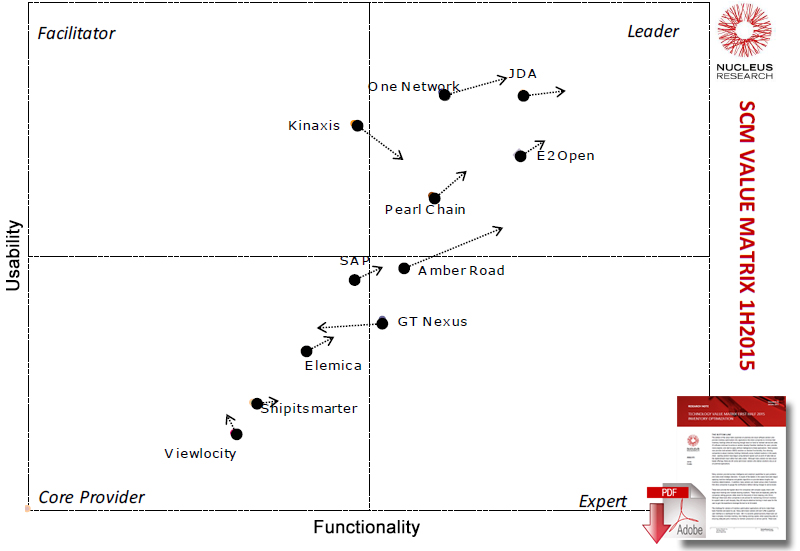

Genpact, the architect of the Lean Digital℠ enterprise, is partnering with One Network Enterprises, a leading provider of multi-enterprise platform-as-a-service and consumer-driven supply chain solutions in the cloud, to help companies automate their order management and supply chain processes with full visibility throughout the enterprise.

Genpact’s Lean Digital approach leverages One Network’s cloud platform, the Real Time Value Network, and allows consumer packaged goods (CPG), healthcare, and high tech companies to drive “perfect orders” across their supply chain operations (demand planning, order management, warehouse management, and transportation) with a single view across the entire lifecycle.

Today’s demanding customers expect immediate, superior service, which places greater pressure on manufacturing companies to improve their perfect order index (POI) and provide more on time, in full, accurate, and damage-free deliveries. Manufacturers and retailers also have a greater need for just-in-time inventory and to tie supplier performance more closely to POI. Yet, supply chain and order management teams often operate in silos which limits the ability to achieve enterprise-wide improvements.

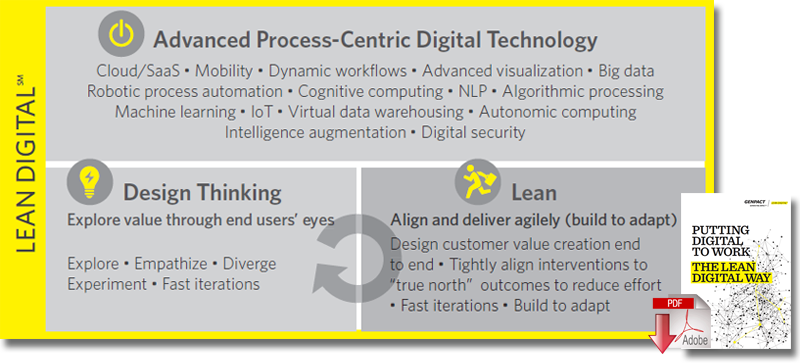

Lean Digital Drives Digital Impact Harnessing Design Thinking & Lean Principles

Lean Digital helps orchestrate three complementary realms. It merges digital technologies, the exploration enabled by the design thinking practices that is increasingly prevalent in the digital world and the classic Lean management principles.

Their combination – a nimble substitute or a precursor of the industrialization traditionally enabled by for instance Six Sigma – help direct digital efforts and focus them on what matters without displacing too many legacy processes and technologies.

And Lean Digital works both for agile custom approaches or crystallized in business transformation methods like Genpact’s Smart Enterprise Processes.

As described in the chart above, design thinking will typically precede and complement Lean at the beginning of the journey. Lean leverages the design thinking ideas and help operationalizing them by keeping into account the legacy environment where those ideas will be implemented.

In the end, for those area where maturity and stability are important, Six Sigma or equivalent can be applied. Importantly though, Lean management practices can be applied almost throughout the entire maturity cycle - always with the objective of avoiding digitizing a broken process.

Digital technologies have become increasingly powerful in this space; however, rearchitecting business processes to realize the full impact is a difficult exercise for many companies, which tend to focus most of their digitization on the client interface.

The Genpact-One Network solution drives more effective and efficient operational transformation by providing enhanced visibility across the entire supply chain, as well as predictive issue identification for order delays or cuts, and proactive resolution and execution through alerts to the order management team.

By harnessing the power of Lean Digital in its relationship with One Network, Genpact provides new ways of operating. Genpact helps makes order management and supply chain operations more intelligent, able to execute faster and more accurately, and adapt over time.

For example, Genpact is using the solution to help a global consumer packaged goods (CPG) market leader transform its order management and supply chain operations to improve its perfect order index, which drives enterprise-wide transformation and improves overall customer service.

“The synergy between Genpact and One Network provides our clients with innovative order management and supply chain automation tools to rearchitect their operations,” said Sanjay Srivastava, senior vice president and chief digital officer, Genpact. “Genpact’s Lean Digital approach and our deep change management experience in the CPG space help deliver transformation efficiently and effectively.”

“We are excited to partner with Genpact, and combine its industry domain and process management expertise with our cloud technology and deep experience in supply chain,” said Greg Brady, chief executive officer, One Network Enterprises.

Article Topics

Genpact News & Resources

Transforming Supply Chain Operations to Deliver Perfect Orders Putting Digital To Work The Lean Digital WayLatest in Supply Chain

A Look at Baltimore’s Key Bridge Collapse—One Month Later European Parliament Passes New Law Requiring Supply Chain Accountability Baltimore Continues Bridge Recovery With Opening of New Channel How Shippers Can Prep for Hurricane Season Apple Accused of Multiple Human Rights Violations South Korea Finally Overtakes China in Goods Exported to U.S. UPS Struggles in First Quarter With Steep Earnings Decline More Supply Chain