The Trade-Offs of Outsourcing Procurement

Before you decide to outsource routine procurement activities, consider what your organization values most.

To streamline their operations, many organizations are looking to outsource activities that do not need to be handled in-house.

The procurement function can be a focus of outsourcing efforts if the organization determines that certain routine activities fall into this category.

The types of activities can vary by organization, but in general they include tasks such as developing and executing simple contracts that involve little negotiation and are not integral to the organization’s overall business strategy.

For many organizations, outsourcing presents a win-win - the organization frees up employees to focus on more strategic duties while maintaining some control over its procurement activities.

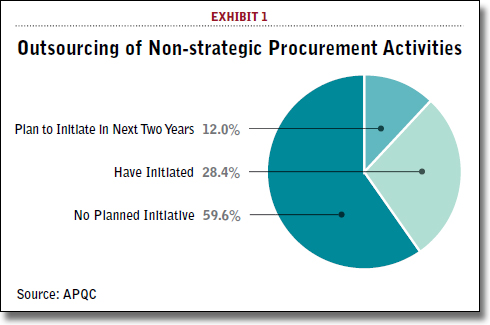

APQC’s Open Standards Benchmarking data in procurement indicates that just under 30 percent of responding organizations have initiated the outsourcing of non-strategic activities in their procurement functions (Exhibit 1).

Twelve percent of responding organizations plan to invest in such programs within the next two years, meaning that 40 percent of organizations in APQC’s data find the idea of outsourcing more routine activities appealing for their procurement functions.

As part of its research, APQC compared the procurement performance of organizations that currently outsource non-strategic procurement activities against the performance of organizations that do not currently outsource. The results indicate that organizations outsourcing more routine procurement activities adopt more mature procurement practices than organizations that do not outsource.

However, these organizations also have slightly higher costs associated with overall procurement processes, as well as with activities specifically related to ordering materials and services.

Performance and Maturity

APQC’s data indicates that organizations outsourcing non-strategic procurement activities have more efficient procurement functions in some respects than organizations that do not outsource.

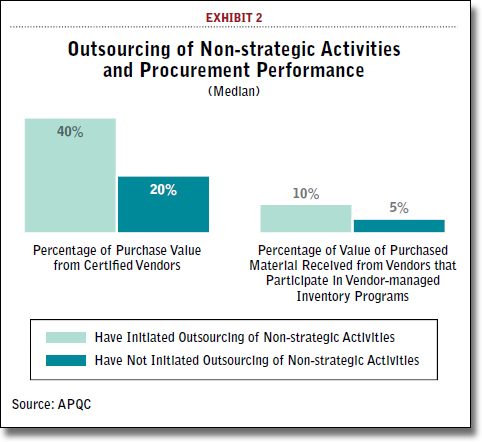

As shown in Exhibit 2, outsourcing organizations have a greater percentage of their purchase value made from certified vendors. At the median, purchases from certified vendors make up 40 percent of the purchase value for these organizations, whereas the organizations that do not outsource have half that amount.

Exhibit 2 also shows that outsourcing organizations have twice as much of their purchase value made from vendors that participate in vendor-managed inventory (VMI) programs when compared to organizations that do not outsource.

The greater emphasis on using certified vendors and vendors participating in Vendor-managed inventory (VMI) programs hints at the presence of more mature procurement practices within outsourcing organizations.

These organizations may recognize the value of using suppliers that have been thoroughly vetted to ensure that they can provide the best value to the enterprise.

Outsourcing organizations may also recognize the benefit of having suppliers manage purchased inventory when possible, which can simplify purchasing processes for at least some of their materials.

These organizations may be able to adopt more mature procurement practices because of the additional time freed up for their procurement staffs with the removal of non-strategic activities; similarly, the focus on using vendors that are certified or participate in VMI programs may be part of a greater effort by these organizations to streamline activities that includes outsourcing more routine activities.

Despite their choices on outsourcing or their adoption of mature practices, the two groups of organizations have similar performance with regard to supplier orders received on time. Both groups have a median of 80 percent of their orders received by the requested delivery date.

This indicates that the potential benefits associated with outsourcing non-strategic activities seem to be limited to internal activities. Outsourcing organizations are able to adopt more mature procurement practices, but seem to be limited in their ability to affect the performance of their suppliers.

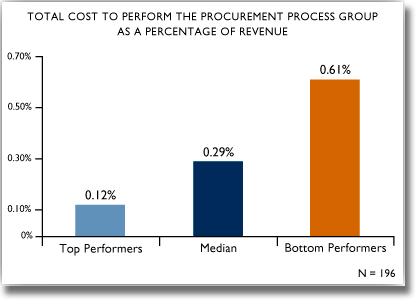

Procurement Cost

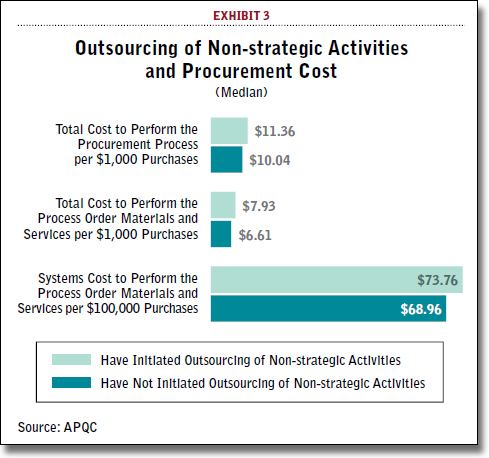

Organizations that have outsourced non-strategic procurement activities may free up employee time to focus on activities more aligned with organizational strategy, but having that extra time does not necessarily translate into cost savings. APQC’s data indicates that these organizations have a higher total cost for the procurement process.

When calculating this total cost, APQC includes costs associated with outsourcing.

As shown in Exhibit 3, at the median these organizations spend $1.32 more on procurement per $1,000 in purchases than their counterparts that do not outsource.

For an organization making $1 billion in purchases annually, this results in an additional $1.32 million in procurement costs associated with outsourcing non-strategic procurement activities.

One factor contributing to the higher procurement costs for organizations that outsource is that these organizations spend more on activities associated with ordering materials and services.

The difference at the median between organizations that do and do not outsource is also $1.32 per $1,000 in purchases.

Accordingly, outsourcing organizations spend more on the systems associated with ordering materials and services. For procurement systems, APQC collects data on the amount organizations spend per $100,000 in purchases.

The difference between the two groups for this metric is $4.80 per $100,000 in purchases at the median. For the organization making $1 billion in purchases annually, this translates into an additional $48,000 in systems cost specifically associated with ordering materials and services.

It is not surprising that organizations engaging in outsourcing spend more on the procurement process given that they must compensate a vendor for handling their non-strategic procurement activities. The higher systems cost associated with making purchases may be due to additional technology that must be in place to communicate with and manage vendors.

Strategic Alignment

Data collected by APQC indicates that outsourcing non-strategic activities from the procurement process can provide some benefits to organizations.

These organizations conduct more business with vendors that have been thoroughly vetted, which allows them to partner with suppliers that can provide greater value and higher quality service.

These organizations also purchase more from vendors that engage in VMI, which removes the responsibility for tracking and ordering some materials from the procurement group.

However, there is a tradeoff for these benefits.

Outsourcing organizations spend more on the procurement process overall, as well as on the activities and systems associated with ordering materials and services. Over a million dollars in potential procurement cost is no small investment.

Is outsourcing non-strategic procurement practices worth it? For organizations that have clearly identified organizational strategies and focus areas, the answer is quite possibly.

These organizations recognize that there are some routine aspects of procurement - such as data gathering, electronic procurement activities, or simple contract execution - that are not aligned with those strategies and thus do not merit time from procurement staff.

In these situations the investment with regard to outsourcing and additional procurement systems allows these organizations to focus more on what they do best and what is important to the enterprise. It also highlights an opportunity for these organizations to carefully evaluate the processes they keep in-house to identify hidden waste.

Further streamlining the activities kept within the procurement function can generate savings that help offset the additional cost associated with outsourcing.

APQC Procurement Open Standards Benchmarking Assessment

Many procurement departments have gone as far as they can when it comes to leveraging price savings out of suppliers.

Download and complete the Procurement Open Standards Benchmarking Assessment and help your department become a core competitive weapon and increase shareholder value.

By participating in this assessment, you can unearth new opportunities for:

- reducing the cost of materials and services,

- increasing supplier on-time delivery rates, and

- improving incoming materials quality.

Other key procurement measures included are:

- average supplier lead time,

- days payable,

- total supplier appraisal costs, and

- total number of procurement employees.

To guide you in your adoption of best practices and implementation of information systems, the report also reviews the following:

- procurement system integration,

- automated procurement processes,

- degree of centralization, and overall procurement strategy of your peers as well as industry at large.

APQC collects data using a Microsoft Excel spreadsheet-based system.

Access Excel data collection tool. This file contains the survey, all related glossary terms, the measures computed by APQC, and a copy of the Process Classification Framework. You may review and complete this file at your convenience.

Send the file as an attachment to [email protected] when you are finished collecting data. For more information, please review our frequently asked questions.

There may be a fee associated with your participation. For more information, please check the Open Standards Benchmarking fee schedule.

If you would like to complete multiple surveys for multiple business entities or in more than one process area, or would like additional guidance, please contact the benchmarking Help Desk at +1-713-681-4020 or [email protected].

Download: Moving Up the Maturity Curve of Financial Shared Services

Article Topics

APQC News & Resources

Talking Supply Chain Podcast: Planning for the supply chain of the future Planning for the Supply Chain of the Future Enhance the Value of Your Supply Chain Supplier Relationships Benchmarks with Becky Partida: Sales order automation benefits the supply chain Millennials in Supply Chain Today’s Millennial Supply Chain Professionals Top Projects for 2016 Supply Chains: Transportation, Sourcing, Resilience, and Inventory Management More APQCLatest in Supply Chain

A Look at Baltimore’s Key Bridge Collapse—One Month Later European Parliament Passes New Law Requiring Supply Chain Accountability Baltimore Continues Bridge Recovery With Opening of New Channel How Shippers Can Prep for Hurricane Season Apple Accused of Multiple Human Rights Violations South Korea Finally Overtakes China in Goods Exported to U.S. UPS Struggles in First Quarter With Steep Earnings Decline More Supply Chain