Service Failures by Outsourcers Reach Top Three Causes of Supply Chain Disruption

Research supported by Zurich Insurance Group has revealed that service failures by outsources reach top three causes of supply chain disruption.

A newly published report supported by Zurich Insurance Group (Zurich) and conducted by the Business Continuity Institute (BCI) highlights the lack of visibility businesses have of their supply chain and the potential disruption that could occur as a result.

In a survey of over 500 business continuity professionals from 71 countries, 75% of respondents reported that they did not have full visibility of their supply chain and that 30% did not know where they fit into any of their suppliers’ priorities. Only 12% knew where they fit into all of their suppliers’ priorities.

Business continuity insurance is not just an insurance policy against an unlikely event. The potential for an ‘incident’ was demonstrated by 75% of respondents recording at least one supply chain disruption during 2012 with 42% of this disruption originating below the immediate supplier. The cost of this is clear as 15% experienced an annual loss in excess of €1 million while 9% experienced a single event that resulted in a loss in excess of €1 million. The key issue for those in the industry is that 62% of respondents felt that top management commitment to managing the supply chain is inconsistent or totally lacking.

Supported by Zurich and also by the Chartered Institute of Purchasing and Supply (CIPS), the report concludes that disruptions continue to have a significant impact on business performance and that the problem is not being effectively managed. One of the key challenges is to get consistent top management support for investing in improved supply chain resilience. Disruptions are not a matter of ‘if’ but ‘when’, so effectively tracking the entire supply chain is essential for reducing the immediate costs of disruption and managing the long term reputation of the business.

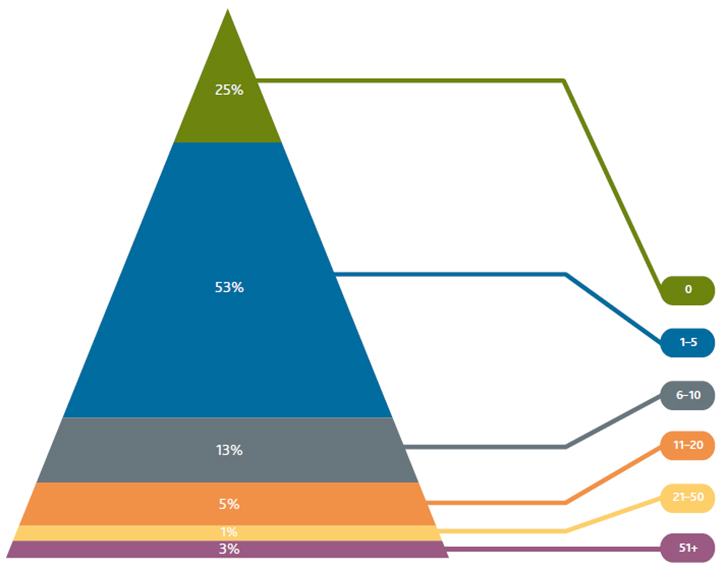

How many supply chain incidents would you estimate your organization experienced in the past 12 months that caused disruption to your organization? Base: 396 who provided a response. A further 79 stated “don’t know”.

Further findings from the report include:

- The leading impact following a disruption is loss of productivity with 55% experiencing this in the last year. 41% reported customer complaints and 33% experienced an increased cost of work and service outcome impaired

- The biggest risk to the supply chain over the next 12 months was reported to be technology (23%) followed by regulations (17%)

- The leading cause of supply chain disruption is unplanned IT or telecom outages with 55% of organizations surveyed experiencing some or high impact disruption as a result, followed in second place by adverse weather, experienced by 41% of firms, then outsourcer service failure at 37%

- 49% of respondents state that half or less of their key suppliers have business continuity arrangements in place for their own needs

Nick Wildgoose, Global Supply Chain Product Manager at Zurich, commented: “It is clear from the results of the latest study that supply chain disruptions continue to have a significant impact on business performance. One of the key challenges is to get consistent top management support for investing in improved supply chain resilience. As a starting point it can be useful to look at your most profitable product or service and look at the profit impact of related supplier failure on your organization. This should get you some attention.”

Lyndon Bird FBCI, Technical Director at the BCI, commented: “This lack of visibility demonstrates just why it is important for businesses to start managing their supply chain more effectively. The supply chain can be complex and is only as strong as its weakest link so with more than four tenths of disruptions occurring below the tier one supplier, businesses must ensure that all those down the chain have systems in place to deal with disruptions. Business continuity plans should be used as an incentive for winning/awarding contracts.”

David Noble, Group Chief Executive Officer at the CIPS, commented: “This report highlights that supply chain risk and mitigating against disaster should be high on the business agenda. The figure of 75% of businesses affected by significant supply chain disruption is staggering but not surprising. The good news is that mitigation and awareness have resulted in fewer high number losses. The loss of talented individuals to manage supply chains remains a significant issue and demonstrates that trained and highly skilled people will continue to be in demand. The high level impact of customer complaints is worthy of note as reputation is key to the continuation of business and a hit to the bottom line. Following this research it appears that until CEOs give it the recognition it deserves, disasters caused by supply chain disruptions will continue to affect organizations.”

Now into its fifth year, the Annual Supply Chain Resilience Survey has established itself as an important vehicle to highlight and inform organizations of the importance of supply chain resilience and the key role it plays in achieving overall organizational resilience in today’s volatile global economic climate.

The outcomes of previous surveys (Supply Chain Resilience Survey 2012) have provided organizations with critical insights and valuable information to support the development of appropriate strategic responses and approaches to mitigate the impact and consequences of disruptions within their supply chains.

Related: All SC24/7 ‘Papers’ on “Supply Chain Resilience”