Reverse Logistics: 5 Steps for Better Backward Operations

Reverse logistics cost is less than 5% of total logistics cost. This is the reason why people call it "Necessary Evil", you don't need it but can't get rid of it.

What is reverse logistics? Why it’s important in modern business and how to create improvement in this area? This article will explain to you the current state of its theories, practices and offer some recommendations.

Current Practices

Reverse logistics is often seen as a clerical function. According to the paper “An Overview of Some Reverse Logistics Practices in the United States” by Olorunniwo and Xiaoming 2011,

- Reverse logistics cost is less than 5% of total logistics cost. This is the reason why people call it “Necessary Evil”, you don’t need it but can’t get rid of it.

- Major causes of product returns are wrong products delivered due to poor process, customer changing minds then make refund and products returned to vendor.

- Most companies see reverse logistics as way to satisfy customer but there is no specific performance measurement for it.

Literature Review

Let’s take a look at academic side of the story. Rubio and Chamorro 2008 explains about current state of reverse logistics research in their paper “Characteristics of the research on reverse logistics (1995–2005)” that major research stream is,

- Development of math algorithm in production planning and design of optimal reverse logistics network

- Literature review and questionnaire based survey about general issues

Infographic

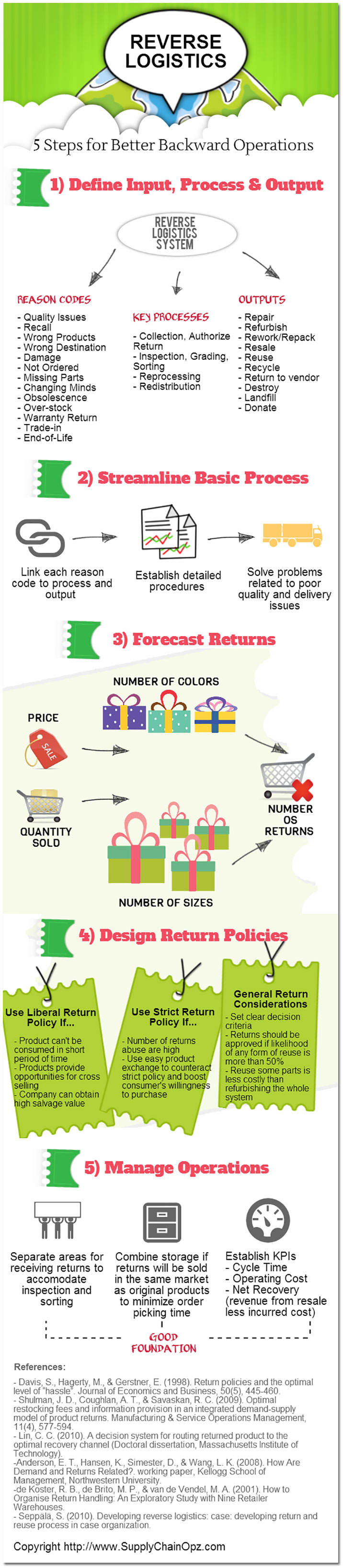

Brito and Dekker 2003 indicates in the article “A Framework for Reverse Logistics” that reverse logistics gain more interest due to lots of pressures from regulatory agencies, customers and corporate social responsibility movement. Anyway, there is a big gap between theories and practices. As a results, infographic is created to demonstrate 5 practical steps that you can improve performance of reverse logistics everyday.

Discussion

Reason code appears to be a very important factor to the success or failure of reverse logistics program. Many surveys indicate that, even though companies have reason codes within manufacturing environment such as type of work-in-process or defects, they don’t keep track of the reasons of returns properly. Establishing more comprehensive reason codes and using control chart to monitor the trend of each code will help company figure out the problems with normal supply chain operations such as sourcing, manufacturing and delivery.

Return policy is also mentioned on many related articles that it’s the important element of reverse logistics. Anyway, paper related to return policy can be found only on journals related to operations management and marketing. Recommendations provided in the infographic is then the results from numerical examples and sensitivity analysis so you are encouraged to examine if it can be applied to your situation.

Another issue is how to forecast demand of returns. Practitioners notice that volume of returns is related to volume of sales but there are only 2 articles discussing about forecasting issue. The information provided in the infographic uses multiple regression analysis to find the relationship between some variables that may influence number of returns.

Editors Note: Original article posted on SupplyChainOpz

Related Article: Why Reverse Logistics Needs to Become a Core Competency Inside Your Supply Chain By Dale S. Rogers, Ron Lembke, and John Benardino

Article Topics

Blumberg Advisory Group News & Resources

Reverse Logistics: 5 Steps for Better Backward Operations Profiting from Reverse Logistics Automation: Results of 2013 Benchmark Survey Closing the Global Supply Chain LoopLatest in Transportation

April Employment Update: Trucking Sector Faces 300 Job Losses Porsche Gets Greener, Shifts to Sustainable Transport Logistics How Much Will it Cost to Repair Baltimore’s Francis Scott Key Bridge? Trucking Industry Pushes Back on Government’s Electric Mandates Maersk Sees Silver Lining in Red Sea Shipping Challenges Baltimore Opens 45-Foot Deep Channel Following Bridge Collapse El Paso Border Delays Cost Juarez $32 Million Per Day in Economic Losses More Transportation