Is Apple’s Supply Chain Really the No. 1? A Case Study

How Complex is Apple's Supply Chain? Some people in the blogosphere said that Apple's Supply Chain is not that complicated.

Apple Inc

Everything about Apple Inc is the talk of the town, for example, the new iPad, iPhone 5, Apple Map or even environmental and labor issues at its suppliers’ facilities.

Surprisingly, IT research firm Gartner ranks Apple Supply Chain as the best supply chain in the world for 3 years in a row.

Without a doubt, Apple Inc is the world leader in Innovation, Branding and Software Ecosystem. But, is Apple’s Supply Chain really the number 1?

This case study will show you the analysis of Apple’s Supply Chain core processes, challenging issues and complexities of its operations.

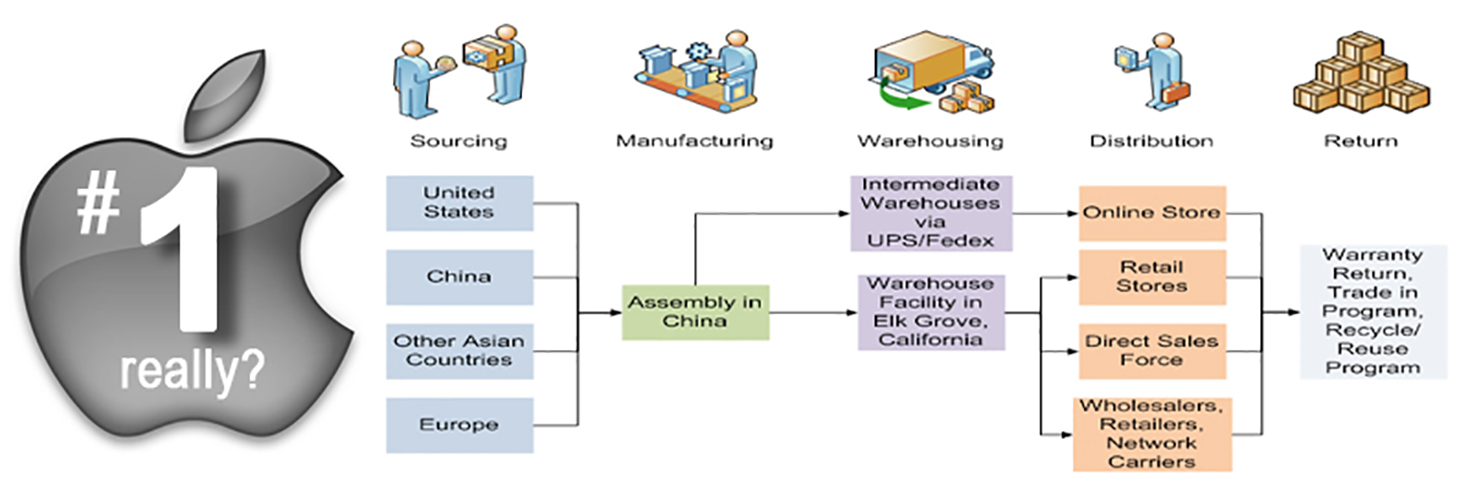

1) Apple’s Supply Chain Model

Information about Apple Supply Chain is a bit here, there and everywhere, it’s kinda tough to find the actual case study.

To the best of my knowledge, many business schools still use the case study “Apple Computer’s Supplier Hubs: A Tale of Three Cities” from Stanford University (1996).

To get a closer look at modern-day supply chain at Apple Inc, this case study utilizes the content analysis technique. Apple’s Annual Report (SEC Filing) of 2011 is analyzed and simplified supply chain processes are constructed as below;

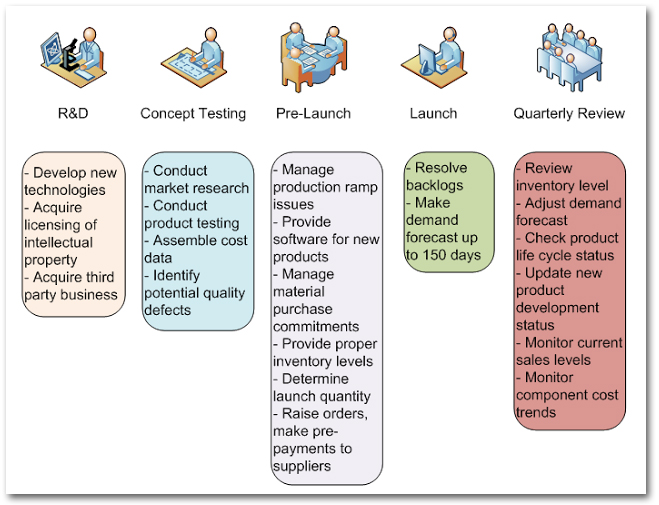

Supply Chain Planning at Apple Inc

Supply Chain Planning at Apple Inc is the classic example of the New Product Development Process (NPD). It’s the integration of R&D, Marketing and various function under supply chain management. From the above graphic, Apple Inc accelerates the new product introduction by acquiring licensing and 3rd party businesses. The whole process looks very similar to that of other industries. Interesting point is that Apple Inc has to make pre-payments to some suppliers to secure strategic raw materials.

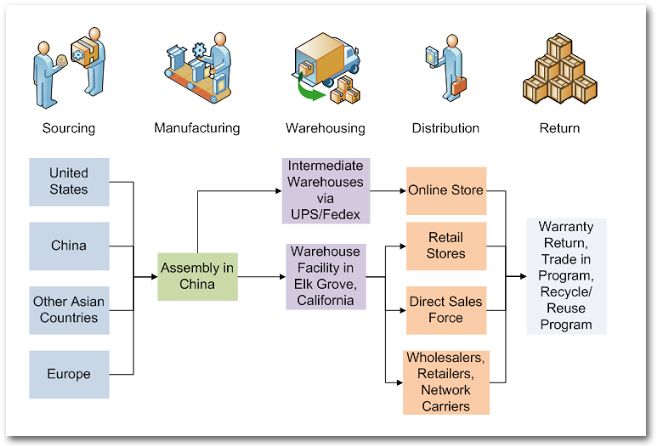

Supply Chain Model of Apple Inc

Supply Chain Map is the way to express large system from points of origin to points of consumption in a simple to understand manner. Information from the annual report is also used to produce Apple Supply Chain Map.

Apple Inc purchases raw materials from various sources then get them shipped to assembling plant in China. From there, the assembler will ship products directly to consumers (via UPS/FedEx) for those who buy from Apple’s Online Store.

For other distribution channels such as retail stores, direct sales and other distributors, Apple Inc will keep products at Elk Grove, California (where central warehouse and call center are located) and supply products from there. At the end of a product’s life, the customer can send products back to nearest Apple Stores or dedicated recycling facilities.

2) Apple’s Supply Chain Challenges

What does it feel like to be “Apple Inc”? One journalist indicated that the life of Apple Inc is fairly easy by utilizing its negotiation power. Believe me, Apple Supply Chain has very high risks. There are many challenges to overcome, for example;

- The global economy could affect the Company.

- Some re-sellers may also distribute products from competing manufacturers.

- Inventories can become obsolete or exceed anticipated demand.

- Some components are currently obtained from single or limited sources.

- Some custom components are not common to the rest of the industries.

- Ability to obtain components in sufficient quantities is important.

- Supply chain disruption such as natural and man-made disasters can be serious.

- The company depends on logistical services provided by outsourcing partners.

- The company also relies on its partners to adhere to the supplier code of conduct.

The above information is also from the annual report. As you can see, most of the risks are on the supply side.

3) How Complex is Apple’s Supply Chain?

Some people in the blogosphere said that Apple Supply Chain is not that complicated. So this section will explain some characteristics of Apple Supply Chain through various metrics and compare them with Amazon Supply Chain.

Inventory Turnover

Inventory Turnover is the traditional financial measure to determine how efficient company uses its financial resources to create sales, the higher number is the better. Supply chain professionals also use this metric in the inventory management function. Generally accepted calculation is (Cost of Goods Sold / Average Inventory).

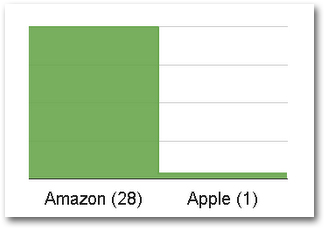

Inventory Turnover of Amazon vs Apple Inc.

The above picture shows that inventory turnover of Amazon and Apple is 10 and 59 respectively (cost of goods sold of digital content/downloadable products are excluded). From the face value, Apple seems to be more efficient.

Anyway, there is a reason for this. Apple Inc is now a marketing company with no manufacturing facility but Amazon is a distributor of general merchandise. It’s pretty natural that Amazon has to keep more stocks then inventory turnover can be much lower.

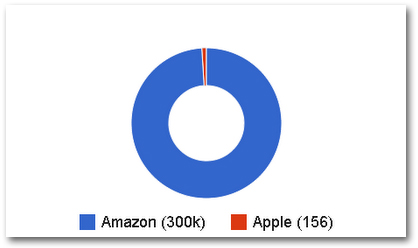

Number of Key Suppliers

Supply chain management is about the relationship between trading partners. Working closely with strategic suppliers will bring competitive advantage to the firm.

Number of Key Vendors Amazon vs Apple

Apple recently said that they have about 156 key vendors across the globe. This amount of suppliers is quite manageable. According to this information, Amazon has about 3 million suppliers in total. Top 5% of this is 300,000 suppliers, way more than that of Apple Inc.

Number of Warehouse Facilities

In the United States, transportation cost is a big portion of the total logistics cost. Then, good management of related function is essential.

Number of Warehouse Facilities Amazon vs Apple

Apple inc has a central warehouse in California but Amazon has approximately 28 warehouses from coast to coast. What Apple has to do is to synchronize data between the central warehouse and its own 246 stores + customers. With the appropriate level of automation, this kind of operations can be done efficiently.

For Amazon, the thing is more complicated than that. Amazon is known to employ many Ph.D. graduates in operations research/industrial engineering. The reason is that Amazon distribution environment must be mathematically solved through optimization method.

Typically, they have to determine how many facilities they should have, where serves which market, items/quantity stored in each location, how to manage transportation between warehouse-to-warehouse and warehouse to customers in order to minimize cost and increase service level.

Number of Items (Stock Keeping Unit)

Stock Keeping Unit aka SKU is another indication of supply chain complexity. One model of phone but different software inside is considered different item/SKU.

Number of SKUs Amazon vs Apple

According to this, Amazon has about 170 million items on its catalog. About 135 million items are physical products. For Apple, they have about 26,000 items (rough estimate, subject to change). The point is that if you have to make a demand forecast, which one will more difficult for you, 135 million items or 26k items.

Product Life Cycle

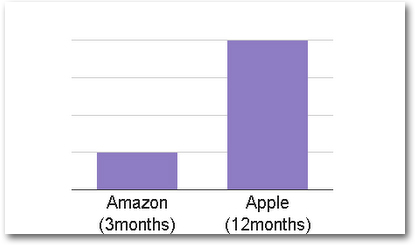

Put it simple way, the product life cycle is how long you can sell products (the longer is the better).

Product Life Cycle Amazon vs Apple

From a rough estimate, Amazon has some seasonal products such as summer wear. They can only sell it for 3 months max. The life of Apple’s key products is way more than 12 months. It goes without saying that demand forecast of seasonal, short life cycle products is very very difficult to estimate.

As you may notice, based on example characteristics, Amazon’s Supply Chain is far more complicated than that of Apple Inc.

4) Conclusion

The results from the analysis of Apple’s processes, challenging issues, and complexities indicate that the success of its supply chain operations depends on how well they manage supplier relationship. This includes early supplier involvement in new product development, close communication, and supplier performance improvement/evaluation. Then, Apple Inc is dubbed as “King of Outsourcing”.

In your opinion, does Apple Supply Chain deserve the number one spot? Register, and let us know your comments below.

Editors Note: Original article posted on SupplyChainOpz