Closing the Global Supply Chain Loop

Ongoing economic “volatility” and the growing global focus on sustainability are placing more pressure on logistics managers to establish a strategic, alternative distribution network. Here’s some food for thought before establishing yours.

The ongoing economic “volatility” is teaching manufacturers and retailers a great deal about squeezing the margins of inventory and creating a viable and sustainable alternative distribution network, says a prominent reverse logistics expert.

According to Dr. Dale Rogers, professor of logistics and supply chain management and co-director of the Center for Supply Chain Management at Rutgers University, logistics managers are under more pressure than ever before because of this new reality. “Rising transportation costs along with global uncertainty and shifting demand patterns have increased the complexity of their missions,” he says.

One trend Rogers points to is less reliance on China. “With the wage structure rising there, and added expenses associated with the reverse cycle, we see a gradual move away from the massive manufacturing sourcing of the past,” he adds.

This will not happen suddenly, cautions Rogers, who maintains that the first temptation for U.S. shippers might be to simply send aftermarket goods into landfills. But with the growing global focus on sustainability, that tactic will not last long.

“Environmental pressures will be exacerbated by commercial forces as well,” adds Rogers. “With the shortage of precious, and rare earth metals, the need for reuse will be enormous. And you can’t return old electronic goods to China—those days are coming to an end.”

At the same time, Rogers says, Brazil and other emerging nations are drafting laws to require manufacturers to recycle unsold goods. This will further complicate a supply chain based on point-of-sale imperatives. “The lack of infrastructure in some of the more remote regions of Brazil makes it almost impossible to regain any margin on the reverse cycle,” he says.

The traction that “near-shoring” is gaining will have an impact in the long-term as well, says Rogers, with more sourcing going to cross-border factories in Mexico. “It will make local refurbishment less costly eventually. This is especially true of high-tech products that require a high yield rate in the secondary market,” he says.

Edgar Blanco, research director at the MIT Center for Transportation and Logistics, says shippers should also keep their eyes on the Caribbean Basin for reverse logistics services.

“The Panama Canal expansion is going to be a game-changer,” says Blanco, “driving a great deal of logistical activity in the region. We are keeping a keen eye on Columbia, for example. Electronics manufacturers there are recycling batteries and cartridges on a massive scale. This is a very aggressive reverse process that neighboring countries are going to emulate.”

Blanco, who also serves as the executive director of the MIT SCALE Network (an international alliance of leading research and education centers) in Latin America says that U.S. manufacturers may even move some repair and repackaging operations in the coming years.

“Miami is already feeling the impact of this, and other major U.S. cities in the Gulf may be next,” says Blanco. “At the same time, however, a secure network of suppliers has to be put in place. This means complete transparency between first-, second-, and third-tier partners. Without that, there’s too much risk.”

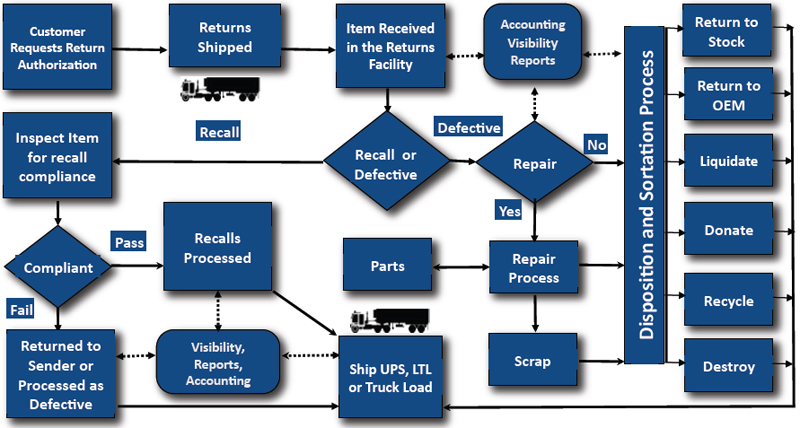

The Reverse Logistics Process

Greve-Davis “A Global Overview of Reverse Logistics”

Inventory Management is Paramount

Supplier transparency is key to any reverse cycle. But supply chain scholars note that other risks must be examined as well.

Diane Mollenkopf, Ph.D., McCormick Associate Professor of Logistics in the department of marketing and logistics at the University of Tennessee, says the tsunami disaster in Japan highlighted the vulnerability of being too lean in terms of inventory protection levels. “One also runs the risk of having too few suppliers, especially when geographically concentrated,” she says. “Shippers will surely be reconsidering how much inventory is really needed in the supply chain, and where that inventory should be located.”

Mollenkopf notes that from a reverse logistics perspective, some shippers may find that they can increase their inventory protection by more effective and timely recapture of return goods. “So an effective reverse flow may help mitigate some of supply risk,” she says.

However, finding a third party logistics (3PL) provider capable of managing an offshore reverse process is still difficult. According to Mollenkopf, the economics of forward and reverse flows pose different challenges. “A good 3PL not only handles transportation, but also has a network of facilities for sorting return goods,” she says. “This is a very specialized type of business, and shippers must make sure that the skill sets are in place before committing.”

Reverse as Strategy

According to Michael Blumberg, a certified management consultant and president of the Blumberg Advisory Group, shippers should seek 3PLs offering a “reverse logistics management” (RLM) program tailored to their specific needs.

“It’s not a ‘one size fits all’ type of business,” says Blumberg. Blumberg contends that RLM also contributes to the bottom line by reducing cost and protecting revenue and should be considered part of your organization’s greater mission. “When you consolidate your administration, you have liability protection and resource optimization,” he says. “Then there are gains in productivity and efficiency. Ultimately, shippers provide customer service and good will that translates into more orders.”

Other analysts maintain that being a good “world citizen” also comprises customer service. According to Gary Cullen, chief operating officer of 4PRL LLC, the reverse logistics arm of The Georgetowne Group, a growing trend of being “cheaper and nearer” seems to fit well within the cost sensitive and “eco-conscious” reverse logistics chain of events.

“Much efficiency can be found in near-sourcing third party service providers who specialize in redeployment, repair, reuse, recycling, reclamation and resale,” says Cullen. “This appears to be a successful business model in today’s fuel conscious and green minded environment.”

Cullen contends that these third party service providers are typically targeted to be near-shore to the originator of equipment being returned, reused, or recycled, and that this new model has many additional benefits.

“A closer country allows for use of cheaper modes of transportation as well as less overall time and movement,” says Cullen. “The goal for near-sourced reverse logistics operations is to reduce movement and handling, and being able to find service providers in the country with the lowest wage and processing costs. Combine this with the improving of your environmental image and you have a ‘win-win’ for your clients, consumers and shareholders.”

Furthermore, says Cullen, 3PLs can protect shippers from “volume unpredictability” and an idle and unproductive labor force. “These near-shore service providers receive their workload from several clients and the total volume received is typically what dictates the amount of labor and facility space required,” says Cullen. “This seems to be a best-cost solution for managing and moving low-revenue and no- revenue used, surplus, and obsolete goods.”

Tips for Outsourcing Reverse

Cullen says he gives shippers two tips for signing a contract with a 3PL when outsourcing reverse logistics. First, make sure that there are clear terms and conditions for running the operation and billing. And second, have a framework to dismantle the operations if it fails.

Curtis Greve, principal at Greve Davis, a reverse logistics consultancy, agrees. “Many companies that outsource reverse don’t seem to think about what they are going to do if they have to fire the service provider,” he says. “Make no mistake, terminating a contact with or without cause can cost millions.”

Greve advises shippers to think about what happens to the inventory, the capital equipment, the building, ongoing worker compensation issues, shut down and closing costs, and the plan for after the 3PL is gone.

“Once they have decided to end the relationship, they could save a lot of money if the contract addresses the shut down process correctly,” he says.