Supply Chains are Underprepared for the Next Big Disruption

Large businesses are more likely to make strengthening their supply chains a priority

Small- and mid-sized companies are underprepared for the next supply chain disruption, according to a report from Dun & Bradstreet. The firm’s Global Business Optimism Insights (GBOI) found that while all businesses in advanced economies identify business continuity, operational resilience, and crisis management as a top risk for 2024, only large businesses are paying attention to strengthening their supply chains as a priority. For small businesses, growth in customer base tops all other priorities, with strengthening of supply chains not even among their top five.

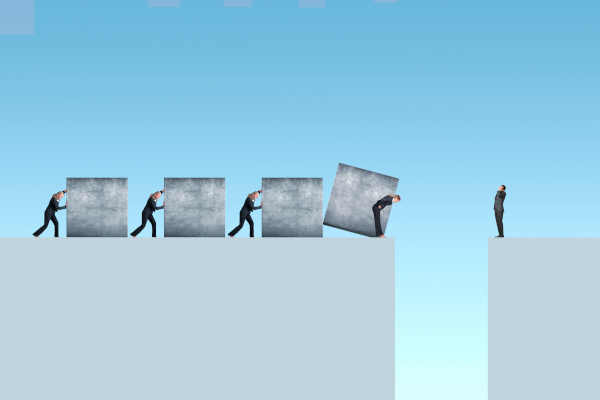

As supply chain continues to grow more complex, however, it will be imperative for businesses of all sizes to address their supply chain challenges. This starts with improving communication among suppliers or even diversifying their supply chains. Those who ignore the warnings are leaving their businesses vulnerable to reputational risk and lost profits.

“Buyers are accepting a disproportionate amount of risk by not doing some of these simple things,” said Steve Yurko, CEO at apexanalytix, a provider of supplier management solutions. “It really is accepting more risk than they should.”

For those focused on supply chain resilience, the GBOI report found that 1 in 3 firms are considering diversifying their supply chains to multiple sources and regions as their top priority, while 1 in 4 are considering improving supplier communication and consolidation. Companies are also focused on localization or nearshoring initiatives, adopting more resilient supply chain models, and incorporating ESG into sourcing decisions.

Understanding your suppliers is key to supply chain resilience

According to Yurko, improved supplier communication is an important first step in prepping your supply chain for disruption. “Just like when you learn algebra, you first need to learn arithmetic, and so the first thing that really is critically important…is really getting a relationship established with suppliers so that you know who they are,” he said.

“Buyers are accepting a disproportionate amount of risk by not doing some of these simple things. It really is accepting more risk than they should.”

Understanding something as basic as where a supplier is located can make a huge difference when geopolitical tensions unexpectedly arise, or a climate disaster threatens a certain part of the world.

Once that relationship is formed between the supplier and the buyer, Yurko said the buyer has an opportunity to help those suppliers identify and mitigate the risks they may have in their business. While he said many see this an obligation, the opportunity lies in ultimately eliminating that same risk in your own supply chain.

“It’s also to help them understand other risk categories that that may exist within that supplier,” said Yurko. “For example, it could be an insurance requirement that the supplier has not fulfilled or met, or there’s a sustainability risk that a supplier is burning too much carbon.”

Better supplier relationships can lead to greater profitability

The benefit of establishing and maintaining these supplier relationships is gaining more information about your supply chain down through multiple tiers, and the outcome of that, Yurko said, is ultimately profit.

“Part of the beauty of our business is the ability to go tell that story with real customers that are actually experiencing that benefit—a profit objective—and that always gets everyone's attention on both sides of the transaction,” he added.

It’s important to note though, that without advanced technology like artificial intelligence (AI), establishing these types of supplier relationships can be challenging. This is likely the biggest obstacle for small- to mid-sized companies that don’t have the resources to focus on their supply chain at a multi-tier level.

Article Topics

apaxanalytix News & Resources

Supply Chains are Underprepared for the Next Big DisruptionLatest in Supply Chain

A Look at Baltimore’s Key Bridge Collapse—One Month Later European Parliament Passes New Law Requiring Supply Chain Accountability Baltimore Continues Bridge Recovery With Opening of New Channel How Shippers Can Prep for Hurricane Season Apple Accused of Multiple Human Rights Violations South Korea Finally Overtakes China in Goods Exported to U.S. UPS Struggles in First Quarter With Steep Earnings Decline More Supply ChainAbout the Author