GE’s $15 Billion Digital Transformation

General Electric Co. is developing software operations in each of its business lines with the goal of building a $15 billion franchise under Chief Executive Officer Jeffrey Immelt’s plan to create a “digital industrial” company.

“We are a company that invests in broad industrial transitions, and they don’t come much bigger than the full application of data and analytics to machines and systems,’’ GE Chief Executive Officer Jeffrey Immelt said in a shareholder letter released Monday.

“Our digital industrial capabilities will expand our growth rate, improve our margins and bring us closer to our customers.’’

As reported by Bloomberg, building out a software business is the next piece in Immelt’s dramatic transformation of GE that includes the sale of the bulk of the GE Capital lending arm.

In addition to unloading about $100 billion in finance assets last year, GE completed the acquisition of Alstom SA’s power generation operations to deepen its bet on the energy markets.

With his annual address, Immelt made a case for GE’s growth prospects in an economy that is “long on volatility and short on economic leadership.”

To remain competitive, he said GE will fund a record level of restructuring this year and aggressively manage costs to capitalize on deflation.

“GE should be a safe investment in a sea of volatility,” he said.

GE Transformation: Creating the Digital Industrial

We are just beginning our transformation as the Digital Industrial Company. The Internet has had a massive impact on consumer productivity and commerce. Its impact on industrial markets is just now being realized. By 2020, 10,000 gas turbines, 68,000 jet engines, more than 100 million lightbulbs and 152 million cars will be connected to the Internet.

At GE, we have decided to generate and model this data ourselves - both inside the Company and with our customers. This is what we mean by becoming a Digital Industrial. Our Digital Industrial capabilities will expand our growth rate, improve our margins and bring us closer to our customers.

There was a time when every sale had a clear endpoint, followed only by routine service and maintenance. Now, sensors on our products send constant streams of data, analyzed and translated into upgrades that drive productivity in industries where even the smallest incremental efficiency can mean very large gains.

Capturing it will be a mission in every one of our businesses. Our aspiration is to offer with every GE product a pathway to greater productivity through sensors, software and big-data analytics.

Why GE? I assure you we didn’t wake up one morning with “software envy.” We have been investing in software and accumulating data for decades.

Competing will not require big acquisitions. Rather, the technology required to compete is in our sweet spot. So, why not us?

Our investments are aimed at delivering more productivity for our customers and GE. The performance, so far, of technology companies to generate industrial productivity has been subpar.

Industrial productivity, which averaged 4% annually from 1990-2010, is only 1% today. This is because pure connectivity does nothing to create value.

Operational productivity requires domain data, physical and digital engineering models, industrial analytics and the ability to modify machines to achieve different outcomes.

Ask a hospital CEO how their results have changed once they implemented a new Electronic Medical Record System, and the answer is typically silence. They still lack the data that drives outcomes.

The “killer app” for the Industrial Internet is GE’s Digital Twin. GE is creating living digital profiles of 500,000+ industrial machines in the field to provide new opportunities for customer growth and productivity.

The Digital Twin is a software model of a physical asset or process that will make it possible to manage more precisely than we ever thought possible and deliver better outcomes. The Twin will create new business models and services for GE’s customers and our businesses.

On the GE90 engine, we have used Digital Twins to increase fleet availability while saving tens of millions of dollars in unnecessary service overhauls. In rail, we are using Digital Twin models of the Evolution Locomotive to enable our customers to minimize fuel consumption and emissions.

The data economy for the industrial world has arrived, and GE is in a unique position to lead it. We enter it bringing decades of deep domain expertise about our industries and volumes of data about our machines and their processes that no one else can match.

Source: Jeffrey R. Immelt, Chairman of the Board & Chief Executive Officer, GE

Letter to Shareholders, February 26, 2016

Read: General Electric Wants a Diverse and Technologically Fluent Workforce Headquartered in Boston

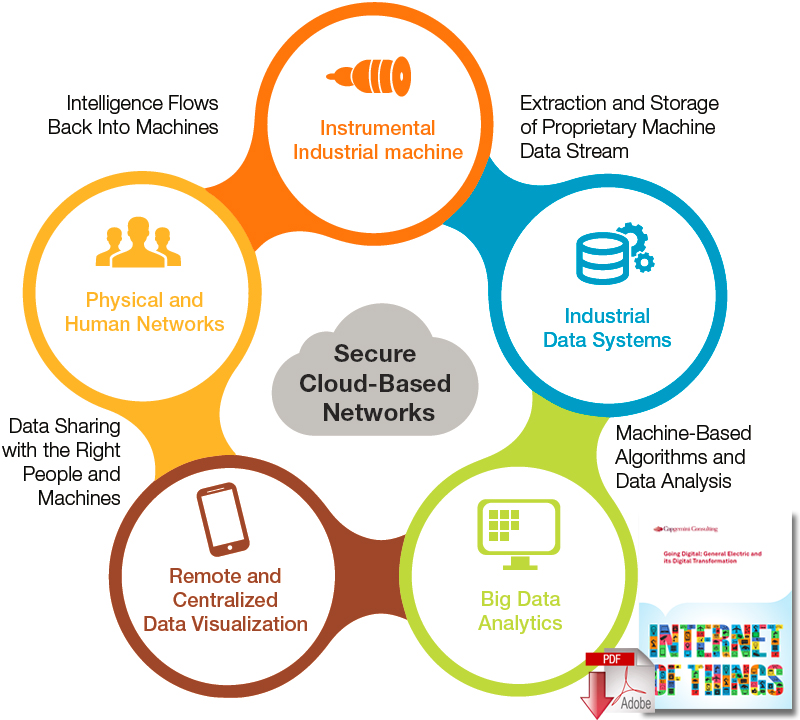

Connecting the Components of the Industrial Internet

GE is attaching sensors to its machines that enable it to capture performance data. This data is then analyzed to provide real-time information to improve machine efficiency, prevent downtime and enable effective scheduling of predictive maintenance.

By attaching sensors to its machines, GE currently monitors and analyzes 50 million data elements from 10 million sensors on $1 trillion of managed assets daily. The overall goal is to move customers toward zero unplanned downtime7 and GE has christened this convergence of industrial machines, data and internet connectivity the ‘Industrial Internet’.

Article Topics

Capgemini News & Resources

Risk Management: Building resilient supply chains in a risky world Reverse logistics in need of some love 2024 WMS Update: At the intersection of warehousing and e-commerce 6 TMS Trends for 2024 Yard Management Systems (YMS): A must-have for the modern operation Six emerging supply chain software trends to watch Steady march into the cloud More CapgeminiLatest in Technology

South Korea Finally Overtakes China in Goods Exported to U.S. SAP Unveils New AI-Driven Supply Chain Innovations U.S. Manufacturing is Growing but Employment Not Keeping Pace The Two Most Important Factors in Last-Mile Delivery Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds More Technology