5 Factors for Achieving Manufacturing Excellence in Good Times or Bad

Despite economic uncertainty and volatility, leading industrial manufacturing firms have posted significant gains in their operating margins. What is the secret to their success? These leaders have made peak performance not just a goal, but a top priority.

A major market change can have profound and long-lasting effects on asset-heavy industries such as industrial manufacturing.

Because manufacturing capacity represents a massive investment that is difficult to relocate or sell off, flexibility and the ability to act quickly to market changes are difficult to cultivate. That makes them enormously important for a competitive advantage.

Despite the economic volatility of the past decade, leading manufacturers have found consistent success. They enjoy better inventory turns, greater operating margins, and higher overall shareholder returns than their rivals.

When downturns hit, they are able to find the volumes and revenues to support their major assets; when the economy rebounds, they are positioned to take advantage of the opportunity. These leaders think and act for both short- and long-term gain.

Five Factors for Success

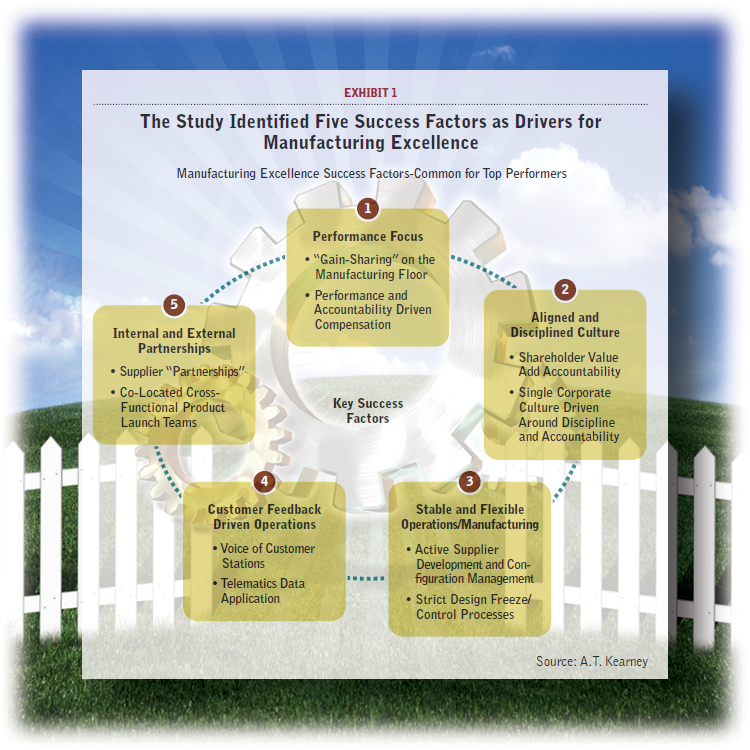

How do these companies manage to consistently stand out? We recently examined the performance of some leading industrial manufacturers and found five major factors that drive their success, as shown in Exhibit 1 and detailed below.

While individual companies may place varying degrees of emphasis on each, this combination of characteristics keeps them ahead of their peers.

1. A companywide focus on performance. Leading manufacturers get the most out of their employees by accurately evaluating their performance and rewarding those who perform best. They create cultures of strong performance, led from the top down by CEOs who encourage well thought out, relevant, and easy to understand targets for all levels of the organization.

These leaders also seek a commitment to closely track those targets and reward top performers.

Gain sharing is one common practice in which those who outperform standards and achieve predefined quality targets receive incentive pay for the improvements they make.

2. Alignment around a disciplined culture. Leading manufacturers embrace consistent corporate cultures that align all parts of the enterprise. At one company, the successful implementation of an aligned corporate culture started at the top, with the CEO making a concerted push for change.

Next, a dedicated unit embraced the culture and promoted it to all units and geographies. Lastly, the culture was put into detailed requirements and applied to all segments of the organization.

Another company centered the corporate culture to focus on shareholder value add performance. Executives were singularly focused on shareholder value and all underlying performance metrics were tied directly to that top-level metric.

As a result, all decisions and actions were motivated by and focused on improving the underlying shareholder value add and all the areas that affect this important metric.

3. Build stable and flexible operations. In a tumultuous business environment, stability and flexibility are vital for managing short-term ups and downs, and creating long-lasting success. Leading manufacturers seek to stabilize internal factors such as processes and programs, including strict design control and the use of simulation techniques to reduce iterations and changes.

Leaders also seek the flexibility to address those areas that are heavily dependent on external complications, such as suppliers, seasonality, and demand fluctuation. One leader tapped into its vendor base to manage inventory and address demand shifts.

It had high expectations for these suppliers, which needed to have co-located staff, warehouses near its manufacturing facilities, and pre-sequenced “day-of” parts handling to provide further flexibility.

One heavy equipment manufacturer strikes a dynamic balance between stable and flexible manufacturing. The first practice seeks stability via those processes that can be directly controlled, such as product configurations and engineering changes.

Then, flexible manufacturing allows for ready adjustments to external factors, such as seasonality and demand fluctuation. Because its production lines are configured to produce multiple products, the heavy equipment manufacturer can better adapt to changing market conditions than most.

4. Collect and use customer feedback. What do customers want? Addressing this question throughout their operations is a key practice for leading manufacturers. Some use customer service metrics for their operations planning, while others involve their customers in the manufacturing and quality processes, using direct customer feedback to help line workers understand what customers want.

This helps employees develop a sense of ownership, accountability to customers, and empowerment, while customers feel like they have a valued personal relationship with the company.

One example of a leading practice for customer feedback is a capital goods manufacturer that implemented voice of customer stations directly on production lines. The stations visually showed customer defects and complaints, as well as positive feedback.

5. Forge strong internal and external partnerships. Strong supplier partnerships and effective internal collaboration can generate significant advantages for manufacturers.

Partnerships can help maximize the value of supplier relationships by giving more responsibility to and rewarding the top-performing suppliers.

One leading manufacturer used a partnership approach to reduce its supply base by more than 30 percent. It offered its top suppliers greater scale and flexibility, but also held them more accountable for better performance. Overall costs fell, performance improved, and the simplified supplier base reduced overall component complexity.

Internal teams are also vital. Connecting cross-functional product launch teams—including product development engineering, manufacturing, purchasing, services (such as finance and HR), and co-locating suppliers—can ensure better collaboration and reduce the amount of design changes. A leading engine producer uses such teams to eliminate “surprises” and minimize design changes to as little as 0.5 per month during product launches.

Working Together

The five success factors are interrelated—for leading companies, performance, culture, flexibility and stability, a customer focus, and partnerships all work together to create short-term success with a long-term advantage.

As volatility becomes the watchword, companies must adopt these types of practices or risk falling behind competitors.

About the Authors: Violetka Dirlea is a partner with A.T. Kearney and is based in Southfield, Michigan. Harris Ng is a principal with A.T. Kearney and is also based in Southfield. Peter Chiang is a consultant with A.T. Kearney and is based in New York City. They can be reached at [email protected], [email protected], and [email protected].

Read the article: “Comprehensive Supplier Risk Modeling”