Kelly-Moore Paint Company & Intelligrated’s Alvey Robotic Palletizers Case Study

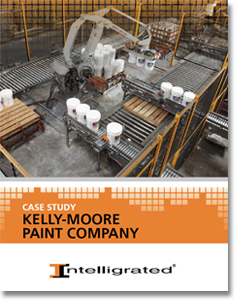

With issues surrounding worker comfort and production efficiency, plant managers at Kelly-Moore’s San Carlos, Calif. facility turned to Intelligrated to develop a robotic palletizing solution.

Based on Kelly-Moore’s original specifications, the system design did not call for the Alvey robotic palletizer to handle pallets.

However, Intelligrated determined that the robot could handle the empty pallet placement at the build positions without significantly impacting the speed of production.

This design change alone saved Kelly-Moore $25,000.

Both robotic arms repeatedly pick and place cans or pails from the infeed conveyors and stack them sequentially on the waiting pallets. Multiple layers are built on the pallet until the pallet load is complete.

Key Benefits: Zero-Pressure Accumulation and Line Changeovers Without Delay or Retooling

Once a pallet is complete, it is conveyed on Intelligrated chain driven live roller pallet conveyor to a new Lantech® stretch wrapper supplied by Intelligrated. “Before, we were securing our pail pallets with rope,” said Hussinger. “The wrapper is a much more forward-thinking piece of equipment, and speaks to the wide range of integration technologies Intelligrated can bring to the table.”

Key to this system was the ability of the Alvey robotic palletizer to accommodate quick line changeovers. This flexibility proved invaluable shortly after installation, when a large Kelly-Moore customer requested a custom run of three-gallon pails.

Although they had the same footprint as the five-gallon product, the new pails were several inches shorter. Intelligrated handled the request with a straightforward pattern addition, avoiding the typical retooling required for a conventional end-of-line installation.

What’s Related

Favorites