Tianjin Explosions Supply Chain Impact: 4 Reasons It’s Worse Than You Think

The effects are being underestimated and will ripple well beyond the immediate regional economic zone and have global implications, the repercussions on the global supply chain will be felt over the next few months and perhaps years to come.

I have been on a mission for the past two weeks to warn the global business community that the impact on global supply chain operations − from the two massive explosions that occurred on August 12 at the Ruihai International Logistics warehouse in Tianjin, China − will be far worse than suggested by news analysts and Chinese officials.

Be skeptical of media reports indicating that business and port operations will shortly return to normal.

This event’s economic relevance and its repercussions on the global supply chain will be felt over the next few months and perhaps years to come.

There are four primary reasons the effects are being underestimated and will ripple well beyond the immediate regional economic zone and have global implications.

First, news media and company stakeholders may not understand fully the economic importance of the Tianjin commercial zone which is enormous. Close to 12 million people call Tianjin home. The coastal city, located 30 minutes by train from Beijing, is a vital logistics and manufacturing hub for northeastern China.

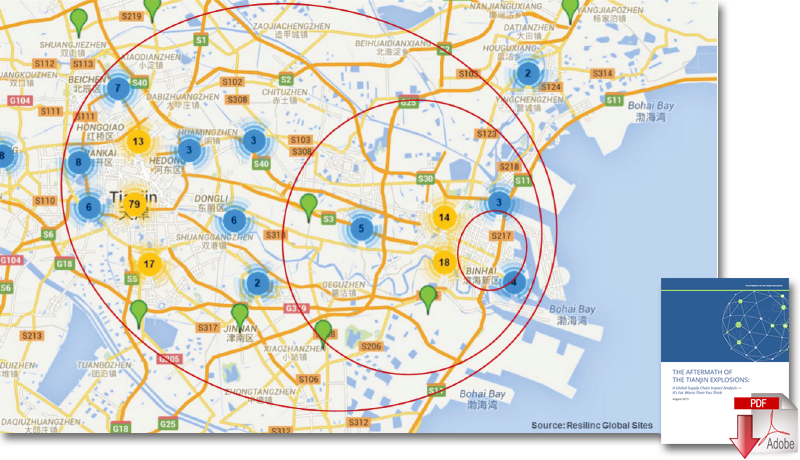

The figure below shows the Resilinc mapped sites in the entire Tianjin region

The clusters demonstrate the concentration of companies who have manufacturing, warehouse, and distribution locations in this important economic hub.

Yellow clusters represent the numbers of sites in region is between 10-100 pins; blue clusters represent the numbers of sites in region is less than 10 pins; circles depict the ripples of impact that can be expected to flow as the disruption waves expand over time beyond the immediate impact zone. Image courtesy Resilinc.

Key global industries depend on the Tianjin commercial area, such as electronics, aviation & aerospace, automotive, petrochemicals, equipment manufacturing, and biotech. The Port of Tianjin is the third largest in the world by cargo volume, and the 10th largest in the world by container traffic.

Second, China carefully controls and filters news and the severity of disruption events is frequently downplayed in China, especially when it comes to disasters that have environmental and human health consequences. What we do know is that environmental officials have expressed ‘concern’ that recorded levels of Sodium Cyanide in the explosion zone were as much as 350 times higher than the safety level and that Cyanide levels in the waters around Tianjin port had risen to 277 times the acceptable level.

This has direct implications for suppliers whose workforce will be unable to return until concerns about hazardous working conditions have been addressed or must stay home to care for children as result of school closures in the evacuation zone or disruptions to the transportation infrastructure.

Some of these suppliers that go lines down represent sole sources of parts required by large global electronics and machinery OEMs to ship their product. And, because these suppliers may be many levels deep in their supply chain, the impact to future shipments and revenue is unknown to them because of a lack of sub-tier supplier visibility.

Third, the potential for long-term environmental and public health impacts that may begin to manifest as a result of several tons of dangerous chemicals polluting the air supply and water table in the region. Chinese and trading partner government reactions could forever change the regulatory landscape for companies operating and utilizing these chemicals worldwide.

Companies should expect and prepare to be affected by new regulations, audit requirements, and heavier fines for their supplier’s non-compliance. I have seen this headline before: public outcry and media criticism about irregularities in compliance and safety standards leads to a government crackdown and shutdown of hundreds of suppliers overnight. Is your critical supplier one of them?

The last reason I am predicting more dire supply chain operational consequences is that companies have been slow to adequately invest in resiliency strategies, processes and tools, such as 24x7 global event monitoring, supply chain visibility/mapping, proactive risk mitigation, and crisis response planning.

The supply chain risk management leaders look at situations like Tianjin not as a threat, but an opportunity to exercise their competitive advantage by being faster to recover and meet customer demand.

About the Author

Bindiya Vakil is the founder and CEO of Resilinc, a cloud provider of supply chain resilience and risk management intelligence and analytics located in Silicon Valley.

Related: More Evidence to the Ongoing Existence of Industry Global Supply Chain Risk