Meltio Robot Cell Includes Industrial Arm for Safe 3D Printing of Metal

Meltio said its new system comes pre-integrated with robotic hardware and software for additive manufacturing of metal parts.

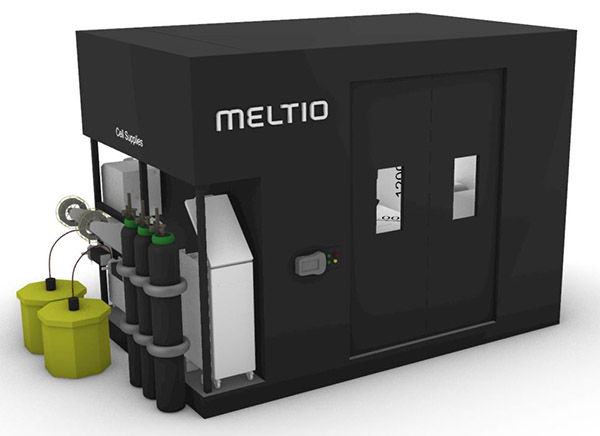

Meltio recently launched its Meltio Robot Cell, which it described as “a turnkey additive manufacturing solution to boost the performance of a industrial robotic arm.” The company said it can improve safety, reliability, and accuracy by controlling the entire process and with its new Meltio Space slicing software.

“Meltio's main commitment with the launch of Meltio Robot Cell is to offer all types of industries the ability to manage the entire manufacturing process using our metal 3D printing technology consisting of a Meltio head integrated in a robotic arm and in a safe environment, in order to just produce parts,” said Alejandro Nieto, Meltio Engine product manager, in a release.

Linares, Spain-based Meltio said it has developed high-performance, affordable, and easy-to-use metal 3D printing systems using wire laser metal deposition (w-LMD) technology. The company said its portfolio includes the Meltio M450 metal 3D printer and Meltio Engine Integration, a 3D printing module that can turn almost any CNC machine, robotic arm, or gantry system into a hybrid manufacturing center.

Meltio Robot Cell comes pre-integrated

The Meltio Robot Cell allows standard metal 3D printing starting from a build plate in a factory, as well as for part repair or feature addition, said the company, whose formal name is Directed Metal 3D SL. By standardizing the integration of the 3D printer, robot, and software, Meltio said it can provide competitive lead times.

“This new hardware system allows the customer to receive a ready-to-use cell for robotic metal 3D printing, removing the integration process and long assembly lead times,” he explained in a release. “The Meltio Robot Cell has a specific area for every supply the cell requires on a daily basis. Only connecting to the inert gas and electric supply is enough to start manufacturing.”

Both the Meltio Engine Integration and the Meltio Robot Cell use the same patented LMD-based process to manufacture parts with both wire and powder simultaneously with the same print head, the company claimed. The Meltio Robot Cell's workspace also includes monitoring and safety features, it added.

The Meltio Robot Cell is tested and certified to operate with an ABB robotic arm in a standard configuration. The base production model is aimed at all industries, said Meltio.

It builds on the Meltio Engine to enable manufacturers to incorporate additive manufacturing with the Meltio head integrated into a robot into their production systems, the company said.

“Meltio Robot Cell also provides the industrial customer with a working protocol,” it said. By being compatible with an open hardware platform, Meltio said it can integrate its 3D metal printing head with any brand of robotic arm to meet customer needs.

The robot and positioner are installed on a self-supporting platform within a laser-safe enclosure with Meltio Engine, Meltio Space, and accessories. Meltio said it designed Meltio Robot Cell as a plug-and-play system, with a single electrical power supply and a single inert gas supply.

The system operates in standard controlled environment, but it is not designed to be used outdoors or unprotected from the sun or dust, noted Meltio.

Pricing and accessories

Meltio said its Meltio Robot Cell is priced below $300,000, which is competitive when compared with other offerings on the market. It claimed that it is also competitive with thermoplastic and concrete 3D printing systems for structural parts.

It said the product has lead times no longer than four to six weeks in 2023.

Upcoming features include an inert bubble, said Meltio. The welding industry has already implemented this hardware option to ensure the best results when printing with high-oxidizing materials such as titanium and related alloys. This could be mandatory in the aerospace sector, said the company.

While the feature's final design is still in development, Meltio reiterated that the Meltio Robot Cell can increase productivity and augment manufacturing capabilities for its clients. The company said it will consider customer requests on a case-by-case basis regarding certification needs and/or low oxidation requirements.

Article Topics

ABB Robotics News & Resources

ABB acquires AI-based autonomous navigation technology provider Sevensense ABB to invest $280 million in its European robotics hub in Sweden ABB Robotics opens U.S. Packaging and Logistics headquarters ABB to expand its robotics factory in Michigan ABB rebrands autonomous mobile robot portfolio ABB survey finds risk from global “education gap” in automation ABB joins Berkshire Grey’s Technology Alliance Program to deliver AI-enabled robotic solutions More ABB RoboticsLatest in Supply Chain

Meet Bluicity: The Startup That’s Predicting and Perfecting the Supply Chain Impending Canadian Rail Strike Could Paralyze Country’s Economy Auto Parts Makers Receive $100 Million to Help Ease Switch to Electric April Employment Update: Trucking Sector Faces 300 Job Losses Reveel Expands Shipping Intelligence Platform with New Parcel Carriers Integration Porsche Gets Greener, Shifts to Sustainable Transport Logistics How Much Will it Cost to Repair Baltimore’s Francis Scott Key Bridge? More Supply Chain