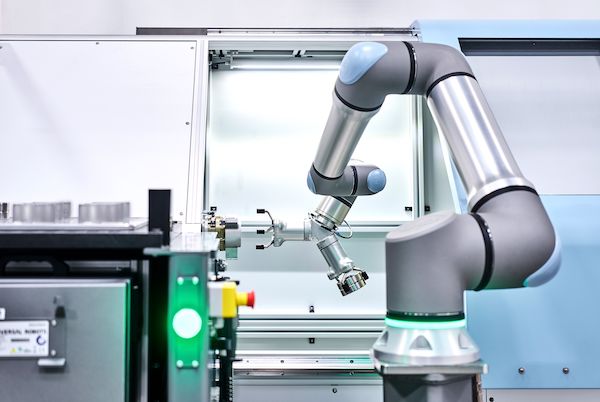

Meet Universal Robot’s New 30 kg Payload Cobot

The UR30 works at higher speeds and can lift heavier loads.

Universal Robots, the Danish manufacturer of collaborative robots (cobots), is expanding its product portfolio with a new 30 kg payload cobot.

UR30 is the second in Universal Robot’s new series of innovative, next-generation cobots and is built on the same architecture as the award-winning UR20. Despite its compact size, UR30 offers extraordinary lift and its superior motion control ensures optimized placement of large payloads, allowing it to work at higher speeds and lift heavier loads. This makes UR30 ideal for several applications, including machine tending, material handling, and high torque screw driving.

“The unique combination of being shorter and smaller, but still being able to handle heavier loads has unlocked a number of applications even our current portfolio of robots with long reach didn’t serve well,” said Anders Billesø Beck, Universal Robots’ vice president, Strategy & Innovation, at the press conference announcing the new offering.

For machine tending, the high payload brings new possibilities as it allows the cobot to use multiple grippers at the same time. This means it can remove finished parts and load more material in one single pass, shortening changeover times and maximizing productivity. UR30 will also effectively support high torque screw driving as it can handle larger and higher-output torque tools.

Thanks to a steady mode feature, UR30 delivers straight and consistent screw driving. This will be beneficial to the automotive industry, for example. In addition, the 30 kg payload makes UR30 a great match for material handling and palletizing of heavy products across all industries, and its small footprint ensures it fits into almost all workspaces – relieving humans of heavy lifting.

Weighing in at only 63.5 kg, the cobot can also be easily moved between work cells. “The higher payload and greater flexibility underpin a new era in automation,” said Universal Robot President Kin Povisen. “Industries around the world are embracing more agile manufacturing and modularity in production – part of achieving that modularity and agility is about mobility, and this cobot delivers that despite its payload.”

Povisen said the UR30 not only meets, but anticipates shifting demands, enabling businesses to adapt and respond to changing needs effectively. “As we continue to innovate, the UR30 is another step in UR's journey in pushing the boundaries of what is possible in the world of automation,” Povisen said.

The UR30 is available for pre-orders now and will begin shipping in Q1 2024.

In other news, Universal Robots announced it is doubling production capacity to meet customer demand for its UR20 cobot, which has become the go-to choice for manufacturers seeking a long-reach, heavy-payload cobot.

Watch this video to get a look at the UR30 launch.

Article Topics

Universal Robots News & Resources

Siemens, Universal Robots, and Zivid partner to unveil smart robotic picking solution Automate 2023 analysis: Simplicity and speed will further robotics uptake Universal Robots predicts 2023 automation trends helping manufacturers meet New Year goals Universal Robots now connect with industry standard protocol Universal Robots launches leasing program in collaboration with DLL Columbia/Okura announces new cobot strategic alliance with Universal Robots Universal Robots launches authorized training centers More Universal RobotsLatest in Supply Chain

Trucking Industry Pushes Back on Government’s Electric Mandates Senators Take Aim at Amazon with Warehouse Worker Protection Act Maersk Sees Silver Lining in Red Sea Shipping Challenges Happy Returns Partners With Shein and Forever 21 to Simplify Returns S&P Global Market Intelligence’s Rogers assesses 2024 import landscape Frictionless Videocast: AI and Digital Supply Chains with SAP’s Darcy MacClaren Baltimore Opens 45-Foot Deep Channel Following Bridge Collapse More Supply Chain