InOrbit Connect Certification Can Simplify the Scaling of Robot Operations

inOrbit says companies can connect robots from different vendors to the cloud with a single click to improve efficiency.

DETROIT—At the Automate trade show here today, InOrbit Inc. launched the InOrbit Connect certification program, which is intended to make it easier for companies to connect robots to the cloud. Operations deploying robots to improve internal processes can add one system or hundreds of robots to their InOrbit accounts with one click.

In addition, with a growing list of robotics providers, a free robot directory will be an invaluable industry resource, said the Mountain View, Calif.-based company.

“Robots are the ultimate data-driven machines, yet it’s still hard for people to get the right insights from their robots at the right time,” said Florian Pestoni, co-founder and CEO of InOrbit. “With InOrbit Connect and the robot directory, we’re able to reduce the friction for end users, who just want their robots to do their job, and robot developers can now focus on addressing the specific needs their robots were designed for. They can each get the data they need, whether it’s to drive operations, detect and resolve incidents, or make their product better.”

InOrbit said its cloud-based, robot-agnostic data platform enables businesses to master “the four O's” of robot operations, or RobOps: observability, operation, orchestration, and optimization. The technology provides secure, real-time analytics and data collection, robot performance monitoring (RPM), incident response, and root-cause analysis.

InOrbit Connect provides single source for data

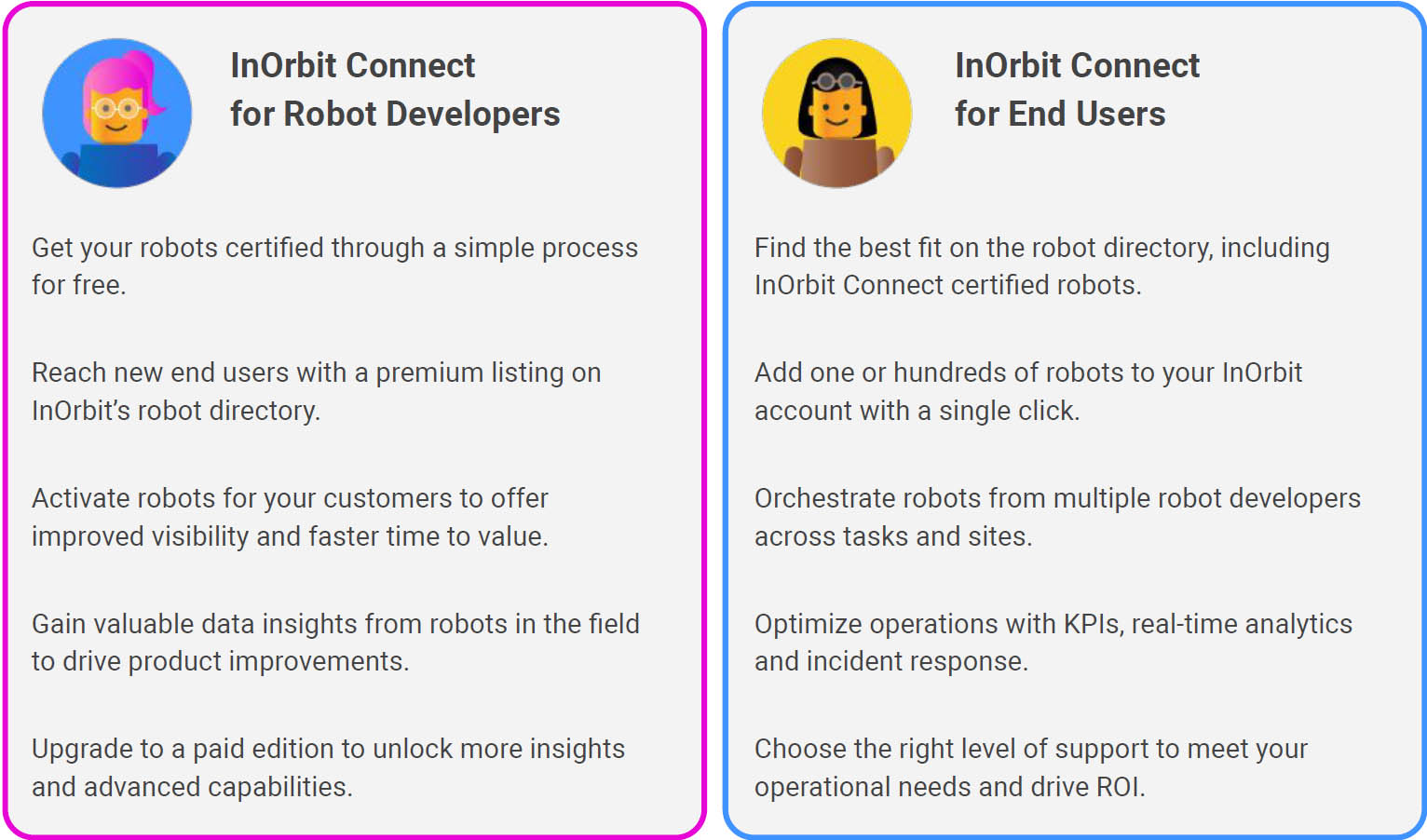

InOrbit claimed that InOrbit Connect is a first-of-its-kind certification program to help connect robot developers and end users. It includes InOrbit Connect-certified robots and is designed to remove barriers to getting valuable, real-time RobOps data across vendors, said the company.

The new program enables robot developers to gather data from all their robots in the field to drive continuous improvement, said InOrbit. By connecting their robots to the cloud with a single click, end users can access all critical operational data in one place, regardless of vendor.

“InOrbit Connect makes this as easy as watching Netflix on a smart TV,” said Pestoni, who is also co-founder of the Robot Operations Group (ROG).

InOrbit offers free and paid editions of its scalable, cloud-based RobOps platform, making it accessible to everyone from early-stage startups to large enterprises.

“In combination with InOrbit Connect, the InOrbit platform provides a single pane of glass for operating diverse and growing fleets while keeping each part of the ecosystem focused on what it does best,” said the company.

Robot suppliers, users to benefit from RobOps data

InOrbit Connect can help robotics suppliers and users manage RobOps data and interoperability among systems.

“Through our work with InOrbit, we are getting critical operational data on our smart autonomous mobile robot [AMR], KIRA B 50,” said Marco Cardinale, vice president of floor care solutions and robotics at Kärcher. “With InOrbit Connect, our customers get the benefits of RobOps with minimum effort, gaining access to real-time, actionable insights that match their needs.”

“As autonomous cleaning robots from Kärcher are deployed in environments such as warehouses and airports with other types of robots, InOrbit can provide an integrated view for maximum efficiency,” he said.

“We are thrilled to be part of InOrbit Connect and to be listed in the robot directory,” said Lucas Jagodnik, CEO of demolition robot maker Apelie Robotics. “As a startup in Argentina working on robotics solutions for specific local needs, we face many unique challenges. InOrbit Connect lets us offer our customers a complete solution for robot operations that’s on par with or above what the largest robotics companies provide.”

InOrbit is exhibiting at Booth 4355 at the Automate trade show, which the Association for Advancing Automation (A3) is hosting this week.