Can Manufacturers Drive High-Performance Supply Chains?

Manufacturers have become increasingly reliant on service providers to run their supply chains, these partnerships offer incredible advantages, but working with multiple enterprises also inevitably introduces risks.

Supply Chain Disruptions

In the last few years, supply chain disruptions have become more rampant.

Today’s gridlock - from geopolitical tensions to increased consumer demand amid material and labor shortages and rising inflation – can be challenging to navigate for even the most advanced, digital supply chains, let alone those with limited visibility and digitization.

While supply chain leaders see technology as a competitive advantage, half of the organizations don’t have a roadmap in place to implement it. Many are focusing on the short-term needs of reducing costs and increasing efficiency. While this is necessary, supply chain technology strategies often focus on narrow sectors and solutions, making investments less than ideal for a long-term digital transformation.

Driving Supply Chain Excellence Through Intelligent Visibility

In the past decades, manufacturers have become increasingly reliant on service providers to run their supply chains. These partnerships offer incredible advantages, but working with multiple enterprises also inevitably introduces risks, such as transport delays, limited visibility, and many interdependencies. The lack of supply chain visibility has caused many manufacturers to adopt a reactionary approach at every point of the supply chain - from managing inventory levels to meeting delivery times.

So, what can be done?

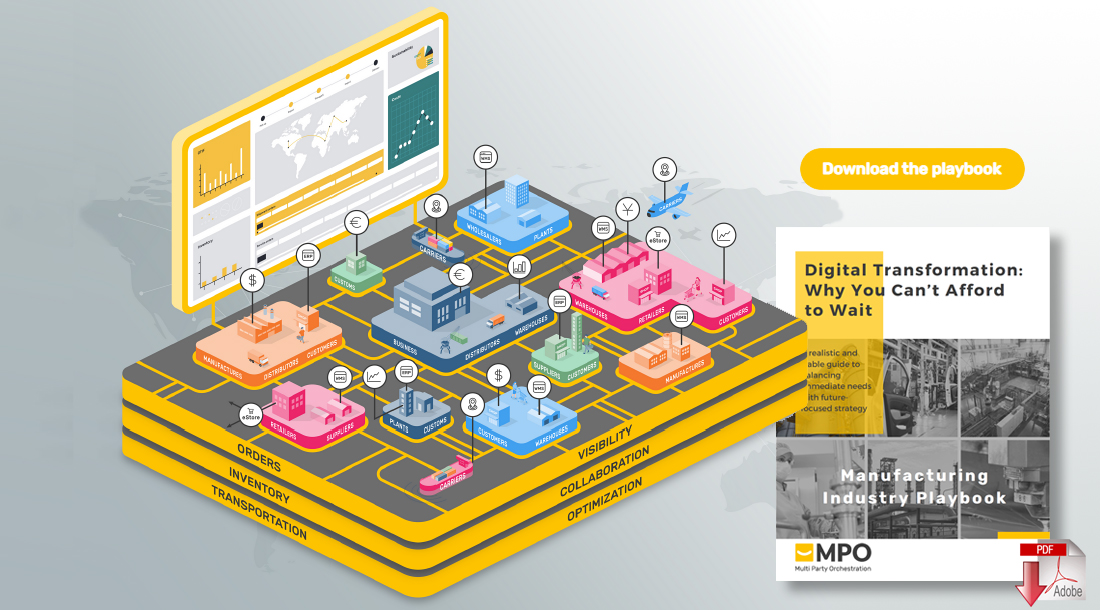

Addressing Wide-Ranging Priorities Begins With Visibility

A good visibility solution for both immediate pain points and future-focused resilience should span the supply chain end-to-end. Supply chain platforms that can integrate with any system, including proprietary ones, enable manufacturers to get real-time visibility into their own facilities, their multi-tier network of suppliers’ facilities, as well as all warehouse and transport activities during order execution. Having visibility over every movement - from order allocation to logistics processes, such as warehouse operations, customs management, handling, and transportation across all modes through to last-mile delivery – improves efficiency, partner collaboration, costs, and service levels.

Applying Automation & Intelligence

Supply chain visibility is only as good as what you can do with it – and how fast. Visibility backed by embedded intelligence and automation helps manufacturers streamline and optimize order planning and execution processes. Supply chain platforms, for instance, can leverage data to support an organization’s “just-in-time” inventory approach. Teams set tolerances based on anticipated orders and client buying cycles, receive notifications if inventory is low, and automate timely replenishment.

Read Strategic Inventory Management: An Alternative to Safety Stock vs Just-in-Time

On the execution side, manufacturers can consolidate shipments and intelligently manage exceptions to increase productivity, service levels, and OTIF delivery. Automation and smart business rules can also be used to optimize reverse supply chains, which often have separate channels. And with a dynamic replenishment plan for manufacturing parts, it’s easier to calculate and maintain the optimal inventory level.

Holistic supply chain software helps manufacturers better utilize their resources, enable smart and proactive event management, and minimize inefficiencies and cost leaks within a volatile environment. With the flexibility to prioritize around inventory, orders, logistics, or returns management, manufacturers benefit from solving immediate pain points anywhere in the order lifecycle, while agilely growing and implementing long-term resilience.

An Eye on the Long Game

The core benefit of adopting a holistic digitization strategy is breaking down silos within an organization’s systems architecture and across partner networks. One central platform for insight into the entire order journey: all legs, transport modes, processes, and parties. Exhaustive documentation into an order’s every movement through the supply chain – whether inbound or outbound – for a full cost-to-serve picture beyond logistics. And the ability to immediately and intelligently act on these insights.

Central platforms lay the critical groundwork for continued growth and expansion. The Internet-of-Things (IoT) is helping to streamline data sharing and communication as more devices, vehicles, and appliances connect to the Internet. Central platforms that are sensor-agnostic help businesses make better data-driven decisions by connecting to the IoT through APIs and make smart use of large amounts of data for improved, actionable visibility.

Artificial intelligence and Machine Learning drive advanced analytics for risk assessment and proactive strategies. Gartner predicts that half of supply chain organizations will have invested in AI and advanced analytics by 2024. But the impact of these technologies will be limited if applied to individual sectors and silos. Every area of the supply chain impacts the other, so manufacturers with their eye on the long game will first unify their systems landscape on centralizing platforms to maximize their ROI on such investments.

Customers and governments also have higher expectations around sustainability initiatives from the manufacturing industry. Embedding sustainability as a key metric will become necessary as companies are required to efficiently meet their CSR goals in the coming years. Holistic, unified platforms support green initiatives from planning and executing orders against the lowest carbon footprint to better managing returns and controlled recycling.

Balancing a long-term strategy while solving immediate pain points is easier than ever before. In today’s volatile global market, manufacturing industry executives are quickly recognizing the value of a digital-first strategy to achieve agility and lasting supply chain resilience. Today’s supply chain platforms offer agile implementation so executives can scale their transformation initiatives and lay the critical groundwork for continuous growth.

CASE STORY

Chemicals Manufacturer Supports Critical Need with Precision & Velocity by MPO

The Power of the Unified Platform

MPO delivered on a systems integration with SAP ECC, ocean booking, customs broker, and dray, as well as the customer’s own plants and 3PL warehouses, enabling go-live in three months. The platform enabled online end-to-end visibility and tracking by connecting multiple legs across multiple modes, and multiple partners.

The manufacturer leveraged the MPO platform to streamline the flow in 3 key ways:

- Automate the order planning process, incorporating customer-specific rules

- Communicate with all service providers for execution

- Proactively alert users of any issues for timely resolution

Download the Playbook - Manufacturing Industry: Why You Can’t Afford to Wait for Digital Transformation

MPO offers a unified cloud platform for Multi-Party Orchestration. The platform complements existing enterprise systems with visibility and control and optimizes order, inventory, and transportation across dynamic, multi-party networks. MPO helps diverse brand owners and logistics service providers embrace the increasing complexity of their global, regional, and domestic supply chains to become more flexible, agile, efficient, compliant, and reliable to their customers. For more information, please contact [email protected] or visit www.mpo.com.

Related Resources

Multi-Party Orchestration Platform

In this brochure, you'll find a guide to MPO's unified cloud platform for multi-party orchestration, including its rich and flexible solutions: Control Tower, Supply Chain Visibility, Digital Order Management, Transportation Management, Network Inventory Management, Returns Management, Spare Parts Management, and Supply Management. Download Now!

Manufacturing Industry: Why You Can’t Afford to Wait for Digital Transformation

This playbook offers Manufacturers a realistic and viable guide to balancing immediate needs with future-focused strategy. Download Now!

More Resources from MPO

Related Article: Why a Lack of Supply Chain Visibility is Costing Your Business

Article Topics

MPO News & Resources

TMS+ Go Beyond Transport to Optimize Cost, Service, & Resiliency Multi-Party Orchestration Platform When It Comes to Digital Transformation You May Not Be Doing What You Think How Chief Operating Officers are Achieving Results with Supply Chain Software SPARK Matrix Transportation Management System Software Analyst Report Top Trends Driving Change and Technology Strategy Within Logistics & Transportation Management 5 Key Steps for Optimizing your Last Mile Delivery More MPOLatest in Supply Chain

Ranking the World’s 10 Biggest Supply Chains The Top 10 Risks Facing Supply Chain Professionals Walmart’s Latest Service: Ultra Late-Night Delivery Dollar Tree’s Oklahoma Distribution Center Decimated by Tornado The Era of Self-Driving Tractor-Trailers Set to Begin Is the Trailers as a Service (TaaS) Model Right For Your Business? Why Grocery Shoppers are Leaving Stores to Buy Their Food Online More Supply Chain