3D printing is emerging as a core focus for UPS

The March issue of Supply Chain Management Review featured an article on the state of 3D printing and additive manufacturing. The timing was prescient, I think, since many of the analysts I’ve read believe that COVID-19 will hasten the adoption of NextGen supply chain technologies.

Two of the co-authors were former and present UPS executives: Alan Amling, a former UPS vice president, is now a fellow at the University of Tennessee, and Dan McMackin is a public relations manager at UPS. While the article was not about UPS, their contributions as co-authors raised the question: So, what’s UPS’s interest in 3D printing and additive manufacturing? To find out, I spoke to Mara Hunt, UPS’s strategy manager for innovation.

“We look at 3D printing or additive manufacturing as the fourth modality of logistics,” Hunt began. “Land, sea and air shipments were the first three modalities, and the shipment of goods digitally is the fourth.” What she means by that is that in those first three logistics modes, physical goods are mass produced, stored in warehouses and then shipped from storage to a customer. Often, those shipments have large minimum order requirements.

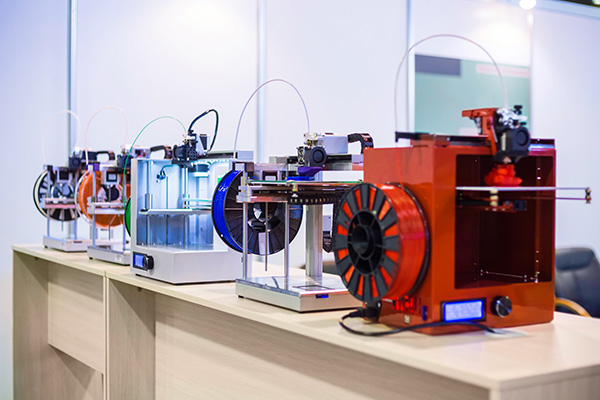

In the digital mode, it’s the design that is stored – not in a warehouse, but in the cloud - and parts are manufactured on demand and in small quantities at a micro-factory, such as space dedicated to 3D printing in a warehouse or distribution center. UPS, for instance, has a micro-factory location in Louisville. It also now offers 3D printing services in some 20 UPS stores around the country. “From the Louisville location, we can get parts almost anywhere in the world in 48 hours,” Hunt said. The company is partnering with Fast Radius, a Chicago-based provider of on-demand manufacturing solutions.

As it develops its digital manufacturing strategy, UPS is eyeing several categories of parts that lend themselves to additive manufacturing. The first category is parts that are difficult to make utilizing traditional manufacturing methods, like a lattice structure. A second is slow-moving service parts that are critical but used sporadically and in small quantities – utilizing 3D printing allows a service parts provider like UPS to reduce its inventory of parts that might otherwise sit on the shelf for months, or years; a third is mass customization, or the ability to customize a part, say with a different serial number, every time it’s printed; and the last is around accelerated product development and prototyping. Designs can be tweaked digitally and 3D printing provides a way to roll a product out at low volumes before shifting to traditional manufacturing at scale as demand increases.

So, where are we, and how might 3D printing change supply chain management? Hunt said that while the cost of printing production grade parts is coming down, we’re still “in a phase of large learnings and rapid innovation,” she said. “It’s a time for experimentation by customers looking to innovate.”

As to the future, Hunt views 3D printing as another tool in the supply chain manager’s toolbox. “It’s another way to optimize your logistics, inventory and warehousing capacity,” she said. “This used to be something we associated with the Jetsons and now it’s coming to life.”