Upgraded Cold Storage AS/RS Boosts Productivity and Labor Efficiency

Cold storage automated pallet storage facility implemented and modified by viastore systems to support new customers’ handling and order profile requirements.

When Americold—the leading global third-party logistics (3PL) provider of temperature-controlled warehousing and logistics services to the food industry— needed to expand its facility space to better serve regional customers from its Indianapolis, Indiana location, the company looked up.

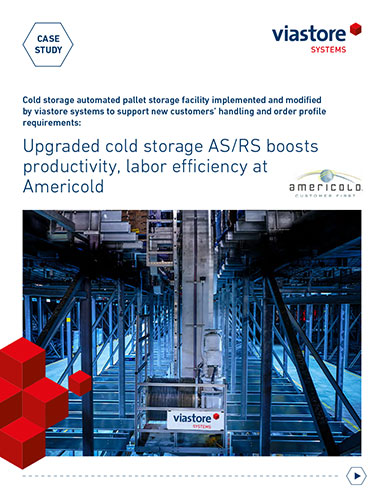

“Having previously expanded a conventional warehouse on this property, we had essentially run out of space to build out,” recalls David Bridger, Americold’s AS/RS Operations Manager at the Indianapolis location. “So in 2011 we worked with viastore to design and build a 110-foot-tall, rack-supported building with a conveyor-fed pallet-handling automated storage and retrieval system (AS/RS) to utilize the vertical space.”

The conventional facility already housed 28,000 pallet positions across 440,000 square feet; when the AS/RS building opened, it added another 21,000 pallet positions in just over 96,000 square feet. The AS/RS was initially engineered with the capability to automatically replenish multi-level order picking positions integrated within the racking structure and pick tunnels at floor level.

The AS/RS also interfaces with a pallet conveyor system for automatic receipt and delivery of pallet loads into and out of the system for storage, outbound staging and order replenishment. For inventory control and order/workflow management, viastore’s AS/RS and conveyor control system, viadat, communicates with a Warehouse Management System (Red Prairie) on the AS/RS side of the facility (the conventional side runs a legacy AS400 WMS but will be converted in the next WMS conversion wave).

viadat directs receipt of pallets through put away to designated storage locations and retrieves pallets to replenish pick locations and fulfill full pallet shipments.

What’s Related

Favorites