Inside the Odom Corporation’s Warehouse: Beverage distribution in Alaska

The Odom Corporation is using lift trucks, high density storage and a pick module to streamline its case-handling operations in Anchorage.

The Odom Corporation

Location: Anchorage, Alaska

Square Footage: 235,000 square feet; 1 of 20 distribution centers of varying size

Products Handled: Beverages including soft drinks, beer, wine and spirits

SKUs: 10,500 active SKUs; more than 30,000 SKUs in Odom’s database

Throughput: 20,000 orders per day, but varies based on seasonality

People/Shifts: 2 shifts per day; 5 days per week

Read the related feature article on Odom Corporation's Alaskan distribution center.

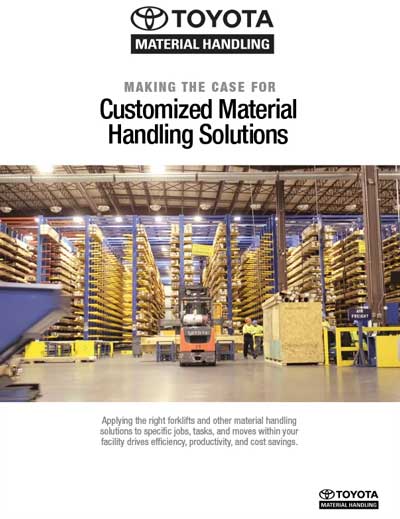

The Odom Corporation’s fleet of 64 lift trucks, with seven more on order, are used in putaway and replenishment, picking and shipping.

Receiving

Receiving happens during the day shift. Given its location, product for distribution arrives by container at the port in Anchorage, Alaska. When containers arrive at the inbound receiving area (1), pallets are unloaded by lift truck and scanned into the warehouse management system (WMS). They are now available in the system.

Putaway

Putaway is system directed. When a lift truck operator scans a pallet, the WMS identifies the storage location. If the item is out of stock in the pick area, it is scanned into a location on the pick line (2). Otherwise, kegs are stored in a cooler area (3), while pallets are stored in selective rack (4) or in the reserve storage area (5) where radio-controlled shuttles choose a location in the 17-deep pallet drive-through rack system.

Picking

Odom delivers full cases, mixed cases and the occasional full pallet. Each has its own process.

Full pallets

Pallets for a full pallet order are scanned and retrieved from the reserve storage or selective rack areas and delivered to the staging area in shipping (6).

Full cases

Full cases are picked from pallets stored at the ground level on the pick line and scanned to a pallet on a pallet jack. There are also ground level pick paths in the reserve storage area.

Mixed cases

Picking of wine and spirits takes place in a three-level pick module known as the bottle room (7). An order begins on the bottom level of the pick module when a case is inducted onto the conveyor system. The case travels through the levels until the case is picked complete and is then conveyed to a staging and merge area (8) where orders are aggregated and retrieved by a lift truck operator.

Packing

Once all of the cases for a pallet have been picked, the pallet is inducted onto an infeed conveyor that feeds an automated stretch wrapper (9).

Shipping

Once pallets are wrapped for shipment, they are staged for loading and shipping.

System suppliers

- Lift trucks, forklift fleet management system, labor management system, pick-to-light and radio-controlled pallet shuttle: Raymond

- WMS: eoStar

- Bar code scanning, mobile computing and voice recognition technology: Honeywell Safety and Productivity Solutions

- Automated stretchwrapper: Wulftec International

- Direct-store-delivery and routing software: Omnitracs (Solera and Roadnet Anywhere)