Advances in Technology Needed for 24/7 Warehouse Operations

CaPow founder says challenges of continuous robotics use needs to be overcome

Today’s warehouse never stops running, but operating seamlessly, 24 hours, seven days per week doesn’t come without its challenges. Inefficiencies, financial drain, and ongoing labor shortages across the logistics industry indicate a change may be needed to keep warehouses profitable and able to meet growing demand.

While companies once would just throw more labor at their problems, the lack of skilled and willing warehouse employees has left room for innovative solutions. Warehouses are increasingly automating manual, repetitive tasks, but as the need for a 24/7 warehouse cycle grows, companies are looking for other technologies to fill the gaps.

Fortunately, this increase in demand goes hand-in-hand with advancements in technology and the way automation complements and adds value to the logistics industry, according to Mor Peretz, professor, CEO and co-founder of CaPow.

“As opposed to the huge facilities of a decade ago, now, there are many smaller or localized logistical setups, sometimes even in the middle of like the metropolitans, because people want to order, and they want to get it very quick. And I think that's where automation really kicks in,” said Peretz.

Overcoming the robotic barrier to entry

Peretz breaks automation into two major segments, the fist being conventional automation in large infrastructure-based warehouses. The second category, which is where he sees an untapped growth opportunity, is a more flexible warehouse, where many of the operational tasks are done by robotics.

In 2022, the warehouse robotics market was worth nearly $6.1 billion worldwide, with estimates the market will reach almost $16 billion by 2030. Peretz believes the use of robotics in the warehouse will continue to grow as they become an essential part to maintaining 24/7 operations. Seeing holes in how facilities currently use robotics, Peretz and his team at CaPow identified several areas they believe are leading to a lack of operational efficiency.

“With today’s typical type of fleets, the downtime issue of the robots in general introduces a significant issue on both the throughput and the operational efficiency of logistics,” said Peretz.

1. Cost of entry

Number one is the number of robots needed to operate continuously. This is not only an energy suck, but it drives up the overall cost of entry. According to Peretz, the ratio between work to charge of robots is between 3-to-1 to 5-to-1. This means that if you have a fleet of 100 robots, you need 130 robots to compensate for the downtime as robots are replenished.

“There are several big players in the industry that are still hesitant of introducing full automation or heavy automation to their to the setups, and one of the reasons is the entry price,” said Peretz.

2. Battery concerns

Another hurdle is battery use. Most traditional robots rely on lithium batteries, which add a layer of safety concerns and maintenance issues. If lithium batteries are damaged or not working, they present a significant risk of fire or explosion. Many warehouses shy away from solutions with lithium batteries because recycling them is also complicated and expensive due to their reactive qualities.

3. Multi-fleet operations

Warehouses that operate with multiple fleets or different makes and models of robots also pose challenges. This means you need multiple chargers and different types of bulky batteries that all allow for different time allocations. This results in a lack of energy and flexibility, and Peretz’s team found it is the root cause of downtime in these facilities.

Is wireless energy the future?

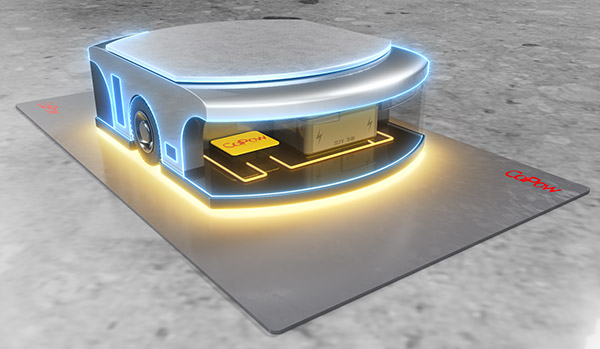

CaPow recently introduced a solution into the market that compensates for the downtime that keeps logistical facilities from operating continuously.

“What CaPow is presenting to the market is basically a way to have energy in motion,” said Peretz. “This translates immediately to 100% of the fleet would work 100% of the time.”

CaPow’s solution works by providing a wireless energy solution that either eliminates or greatly reduces the need for batteries. It also consolidates energy use into a single source, rather than relying on several different types of chargers and batteries for different robotics solutions. The solution allows for a warehouse to simply calculate the robots needed to execute the task.

“When you sum up all of these benefits, you significantly increase the operational efficiency of the logistical fleet and provide much better utilization of the robot,” said Peretz.

Article Topics

CaPow News & Resources

CaPow’s power-in-motion solution eliminates charging downtime Advances in Technology Needed for 24/7 Warehouse Operations Perpetual Power Comes for AMRsLatest in Warehouse|DC

Ranking the World’s 10 Biggest Supply Chains The Top 10 Risks Facing Supply Chain Professionals Walmart’s Latest Service: Ultra Late-Night Delivery Dollar Tree’s Oklahoma Distribution Center Decimated by Tornado European Parliament Passes Law on Supply Chain Accountability Transforming Warehousing with AI: Five Key Reasons to Adopt Now Talking Supply Chain: Understanding the FTC’s ban on noncompetes More Warehouse|DCAbout the Author