What generative AI means for supply chain work

The new technology will touch most aspects of the supply chain and make professionals more productive in their day-to-day work.

Fifty-eight percent. This is the portion of supply chain processes that generative AI will either automate or augment. The number comes from research Accenture has done recently and provides a sense of the technology’s transformative potential.

The changes generative AI drives cover all domains of the supply chain.

1. Designing and engineering. Generative AI solutions that tap into historical data will save designers and engineers time and effort, especially during design iterations.

Take packaging design. Professionals must consider many factors like sustainability, ease of transport, durability, regulations and branding, which eats into their timelines and resources. Generative AI can serve up multiple design concepts and propose suitable packaging copy at will. Designers and engineers can then review these concepts to ensure compliance with product and regulatory requirements.

Another example are applications for biopharmaceutical companies. Terray Therapeutics uses generative AI for small-molecule drug discovery. Its foundation model for chemistry translates chemical structures into numerical representations, allowing generative AI to design novel optimized molecules.

2. Planning. Generative AI promises better access to the insights supply chain professionals need to plan and optimally match demand and capacity.

Many companies have analytics solutions in place to generate these insights. However, these insights are often complex and could be easier to use in practice with the right context.

Generative AI solutions cut through the maze with easy-to-use interfaces through which workers query recommendations and receive explanations in everyday language. It also allows more unstructured data sources, such as market reports, news articles, and social media, to be added to the models for forecasting calculations.

3. Sourcing and procurement. Imagine if every business user had an assistant buyer powered by generative AI. When they need to buy something, the assistant guides them to the right buying channel, supports any call-off or spot buy, and connects them with a professional buyer to handle the purchase.

“Applying generative AI to large volumes of unstructured procurement information, such as contracts, policies, and product specifications, could quickly identify common patterns and requirements. ”

Text-heavy tasks like contract generation stand to make significant gains as well. Applying generative AI to large volumes of unstructured procurement information, such as contracts, policies, and product specifications, could quickly identify common patterns and requirements. The AI could then instantly draft a new contract to be reviewed and enhanced by the procurement team.

4. Production. Maintenance teams often grapple with complex activities and bulky asset-specific documentation. Generative AI can digest this information and summarize it into a series of logical steps as part of a maintenance work order. Expert know-how is decoded and made available across the workforce in real-time and everyday language.

Now consider maintenance planning. Many companies in heavy industries apply risk-based inspections. Planning for these inspections is a manual, time-intensive and repetitive process. It also needs highly skilled field engineers to create planning

documents and experts to review them.

Generative AI can write precision maintenance job plans for equipment classes or specific equipment wholly and accurately. This reduces the time needed to create and review planning documents significantly.

5. Fulfillment. Fulfillment operators benefit from generative AI through better transportation management and forecasting. The technology lets them consider more factors from unstructured information, such as weather forecasts and competitor activity, in their final decision-making.

Consider a generative AI-powered import/export document generator for shipping and export processes. It could tap wagonloads of unstructured information, including historical internal records and governmental regulations, in various formats. Shipping and export documents are automatically populated to be reviewed and verified. This would reduce errors and save time and manual effort.

Other key areas of impact

Companies are under pressure to increase the sustainability of their supply chains. The information they require to do so is usually dispersed across many sources. Collecting and analyzing it requires intense manual effort. Even for subject matter experts, this is often slow work.

Generative AI offers solutions to this challenge.

A global pharmaceutical company spent years painstakingly compiling data on how many suppliers had science-based targets—until a new generative AI solution delivered the insights in an hour.

Take Scope 3 emissions reporting. A generative AI solution from Accenture sifts through millions of lines of spend data in multiple languages and automatically maps each line item to emissions factors, which procurement teams can review. A process that once took days can now be completed in minutes.

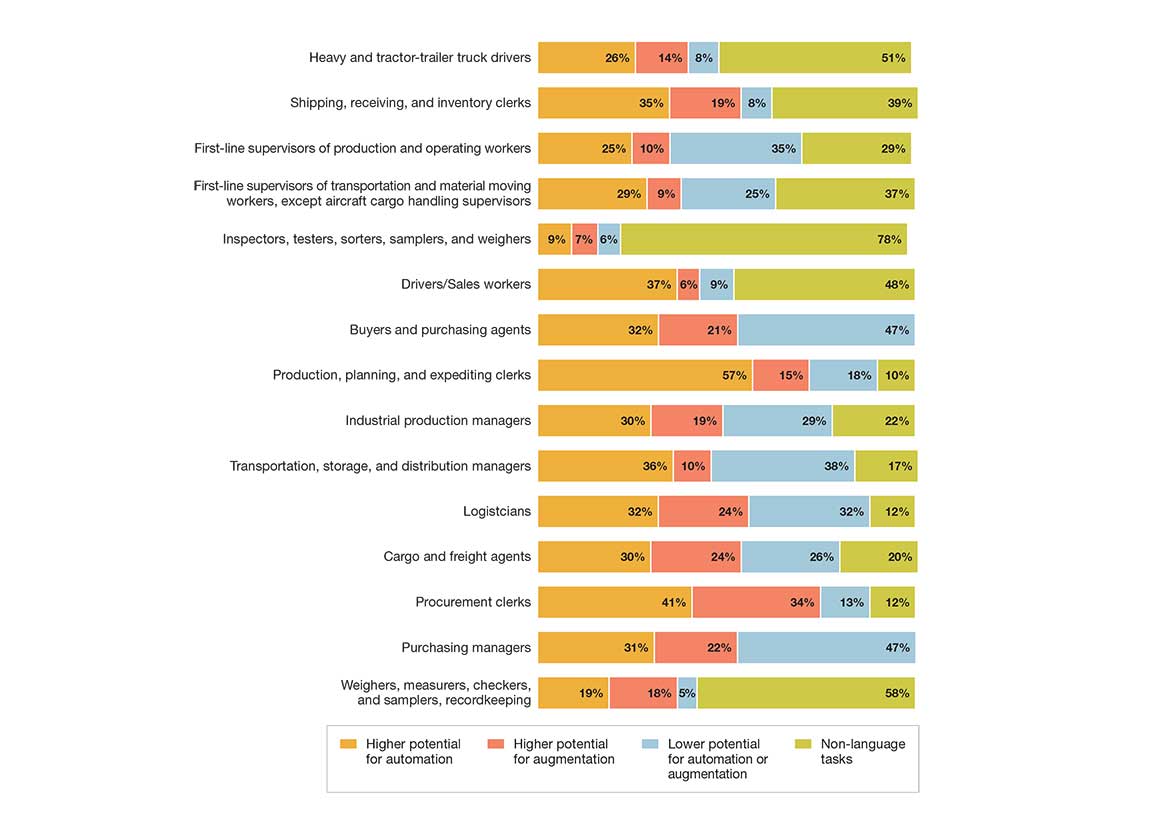

Work time distribution by occupation and potential impact of generative AI

(Ordered by employment levels in the U.S. in 2022)

Accenture’s research also found that generative AI could change 43% of all working hours for supply chain professionals in the United States.

The roles of procurement clerks and production, planning and expediting clerks are likely to change the most. Seventy-five percent and 72% of their time, respectively, are susceptible to change.

The high numbers don’t necessarily equate to job losses. Rather, they indicate that generative AI technologies could augment many of their tasks. Procurement clerks, for instance, could rely more on generative AI applications when evaluating the quality and accuracy of data and determining the value or price of goods and services.

Using such applications would allow them to reallocate their time to more value-added activities, such as supplier development programs, joint new product development, and strategic interaction with business partners.

“It’s incumbent on supply chain leaders and workers to understand and plan for this change of work on two dimensions: which tasks can be automated or augmented, and which people need to be upskilled to use generative AI.”

It’s incumbent on supply chain leaders and workers to understand and plan for this change of work on two dimensions: which tasks can be automated or augmented, and which people need to be upskilled to use generative AI. By analyzing these factors, companies can map out what it would mean for their people and develop the right upskilling programs in a responsible way.

Companies should approach generative AI not merely as “just another” technology implementation. It’s part of an effort to reinvent the enterprise, with implications for how an organization thinks about its data, talent, processes and ways of working.