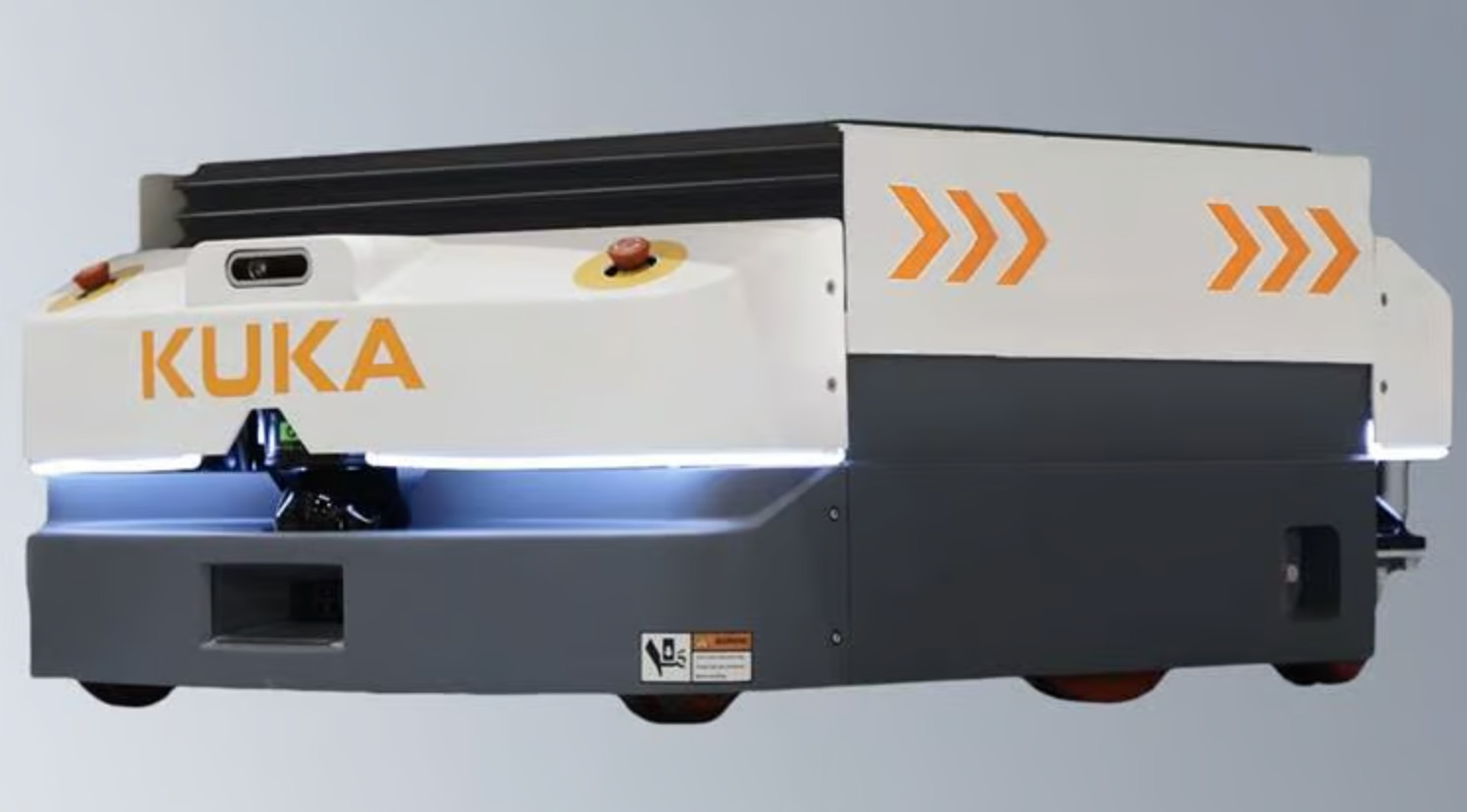

KMP 600-S diffDrive Mobile Robot From KUKA Designed for Swift, Safe intralogistics

KUKA said its collision-free "coworker" can take intralogistics to a new level, especially in the consumer goods industry.

Mobile platforms must meet strict requirements for industrial use, according to KUKA AG. The company last week said its KMP 600-S diffDrive provides its new automated guided vehicle, or AGV, with high-speed support for production intralogistics and a payload of up to 600 kg (1,322.7 lb.).

The AGV can move up to 2 m/sec. (4.4 mph). In addition, the KMP 600-S diffDrive is suitable for the everyday rigors of production environments, claimed KUKA. The robot's IP 54 design enables it to work reliably even under adverse conditions—including water spray and dust, it said.

Augsburg, Germany-based KUKA is a unit of China's Midea Group and provides industrial automation for healthcare, automotive manufacturing, and logistics, among other industries. The company has U.S. offices in Michigan.

KUKA designs for maximum safety, flexibility

KUKA said that all of its mobile robots guarantee employees maximum freedom of movement without the need for safety fencing. The KMP 600-S diffDrive includes laser scanners mounted at the front and rear.

These sensors allow for safety and high speeds in all directions of travel when required by cycle times, the company said.

“Safety is a central concern for us,” said Jakob Brandl, portfolio manager at KUKA. “That’s why the KMP 600-S diffDrive uses eight safety zones at both the front and rear – customizable for vehicle speeds and specific applications.”

KMP 600-S includes multiple interfaces

Engineers can add 3D object detection to expand the KMP 600-S diffDrive so it can detect obstacles from 50 mm to 2.1 m (1.9 in. to 6.8 ft.) above the ground. They can also link the new platform to a wide variety of workstations for specific load-handling options, said KUKA.

For example, the company epxlained, the robot can act as a top-load AGV, and it can lift pallets or cartons up to 60 mm (2.3 in.) via its integrated lifting device.

KUKA.NavigationSolution provides fleet management

Users can start up the KMP 600-S diffDrive with a manual controller and program applications in Java, said KUKA. With an operating time of around eight hours, the KMP 600-S diffDrive can recharge in two hours.

KUKA.NavigationSolution monitors an entire fleet, KUKA said. It detects battery charge levels and identifies which vehicles are connected to the WLAN.

After initial environment teaching through the SLAM (simultaneous localization and mapping) algorithm, the software takes over localization in space (on the vehicle itself) as well as vehicle coordination (on a central computer).

The fleet manager uses parameters such as distance and speed to determine the best route on the network of paths – avoiding all collisions, said KUKA.

The global market for mobile robots could expand from $4.7 billion in 2022 to $8.9 billion by 2028 at a compound annual growth rate (CAGR) of 11.2%, in part due to the COVID-19 pandemic, forecast Research Reports World.

Infiniti Research Ltd. predicted a CAGR of 16% and growth of $2.1 billion between 2022 and 2027. Similarly, Technavio estimated a CAGR of 16.43%, with 48% of that growth in Asia-Pacifc.

KUKA said it plans to show the KMP 600-S at upcoming events, including ProMAT 2023 in March in Chicago.

Article Topics

KUKA News & Resources

KUKA highlights next-generation mobile robotics for production and storage Swisslog names Jens Schmale as new CEO effective start of 2024 Food and beverage challenged to do more with less ABI Research: Manufacturer adoption of collaborative robots is strong Collaborative robot automates small-item picking at Swisslog Peek Inside Trinchero’s New Automated Warehouse Automated material handling equipment market is expected to reach $44.68 billion by 2022 More KUKALatest in Supply Chain

GXO Logistics Deploys 500 Robots for Top Sporting Goods Retailer Talking Supply Chain: Why a Stanley cup can disrupt the supply chain UPS Cuts Email Response Time in Half with AI Automation 2024 Salary Survey: Supply Chain Professionals Now Earn Over $100K Five Innovations Shaping the Future of Last-Mile Delivery Barge Hits Texas Bridge in Incident Reminiscent of Baltimore Collapse April Retail Sales Stagnate but Show Annual Growth More Supply Chain