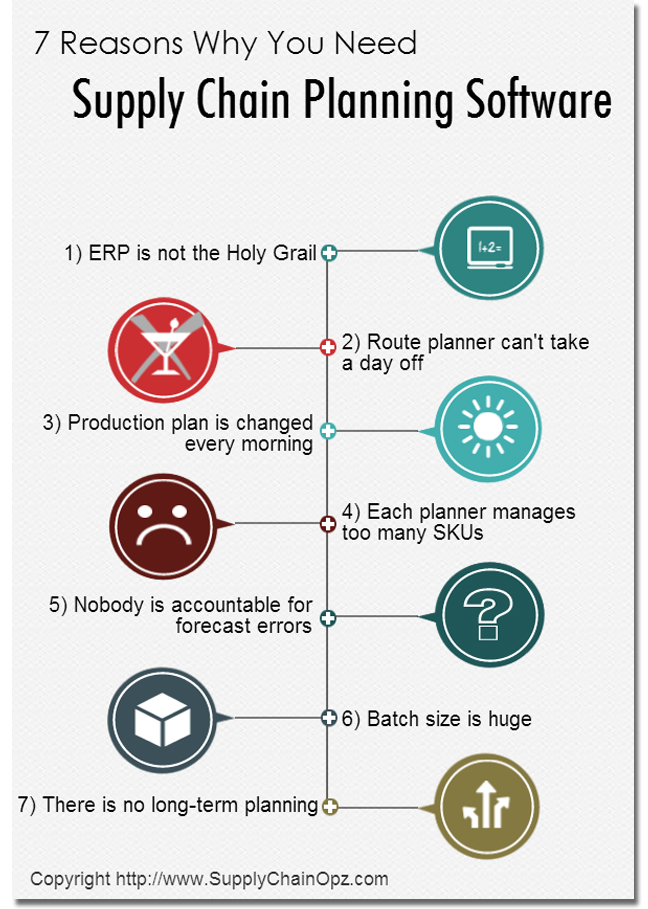

7 Reasons For Supply Chain Planning Software

Many companies use the word "supply chain planner" to describe an entry level job dealing with the demand forecasting and material scheduling but is this the entire scope of supply chain planning?

Supply chain planning has been recognized as one of the best practices due to the force behind globalization and higher level of competitions.

Considerable cost savings can be achieved when it’s implemented properly.

This article will explain its basic concept and some reasons why you may need the help of supply chain planning software.

Basic Concept

Many companies use the word “supply chain planner” to describe an entry level job dealing with the demand forecasting and material scheduling.

Is this the scope of supply chain planning?

According to the generally accepted principle, supply chain planning is the time based decision making process such as Strategic Level (Network Planning), Tactical Level (S&OP, Demand Planning), Operational Level (MRP, Capacity Planning, Production Scheduling, and Vehicle Routing) which is illustrated below;

- At the strategic levels, a company tries to figure out the best strategy to deal with long term capacities, facility locations, stocking points and management of distribution channels for the next 2-3 years.

- At the tactical level, planning process starts with the annual budgeting. A company makes a sales projection for the next fiscal year, identifies required investment, materials, capacity and labor and tries to bridge the gap between the demand side and supply side.

- At the operational level, a company deals with day-to-day operations such as Material Requirement Planning (MRP), material scheduling, production planning, sequencing, order release, order promising and vehicle routing.

Supply chain planning can be done manually but there are signs you might need a planning software as below;

1) ERP is not the Holy Grail: the expectation is usually high when a company decides to invest in a new enterprise software system. However, many of them find out later that a standard ERP system only enables them to manage the enterprise information in a big database. Many complicated analysis must be done outside the system. If you already have an ERP system in place, a good planning software can a very good addition.

2) Route planner can’t take a day off: if you’re still doing the vehicle routing manually, you’ll notice that the quality of the route is not very good. The reason is that many route planners have developed their own unique ways to handle real world constraints such as time windows, truck ban time period, vehicle capacity limit, rush order and so on. The process is so complicated that nobody can imitate the planning logic, that’s why a planner can’t take a day off.

3) Production plan is changed every morning: in some industries such as in Electronic Industry Services (EMS) in Asia, changing a plan every morning is the way of life. The reason contributing to this problem is mainly from the negotiation power of big customers who can ask for order insertion, deletion or cancellation any time. Then, you need a software that help you create a plan quickly.

4) Each planner manages too many SKUs: how many SKUs should a planner manage? Generic answer is something around 500 SKUs. If your planner is currently dealing with 2,000 SKUs or more, using a spreadsheet analysis can be problematic.

5) Nobody is accountable for forecast errors: a demand forecaster usually feels a bit lonely because he/she is to blame for the errors. Good S&OP software can be the ideal solution that brings marketing, production, logistics and finance department together and create a realistic demand and supply plan.

6) Batch size is huge: it goes without saying that a big production batch drives cost down a lot due to lower machine set-up and higher yield. The drawback of big batch size is the lack of responsiveness. A good planning software can help to create more flexible plan without sacrificing too much of the economy of scale.

7) There is no long-term planning: have you ever wondered what you should do for the next couple of years to come? Most companies do a strategic planning such as industry analysis, competitor analysis, new production development road-map and so on. The problem is that supply chain people usually don’t take part in this kind of initiative. Then, an implementation of supply chain planning software is highly recommended.

Source: SupplyChainOpz

Navigating a Course with Planning & Forecasting

When it comes to Sales and Operations Planning (S&OP), forecasters and planners need to work together to achieve financial performance targets…...read more