Zebra Expedites Orders with Its Own Real-Time Locating Technology

RTLS Drives Productivity and Efficiency at North American Distribution Center.

The Challenge

From its 72,000 square foot distribution center in Vernon Hills, Illinois, Zebra Technologies processes and picks more than 16,000 items comprising printers, RTLS equipment and accessories every day. The location serves customers and partners across North America and Latin America.

Zebra’s North American operations recently initiated a multi-year program focused on systems and processes to support its overall business transformation. As part of that, the company deployed Oracle, allowing it to connect many stand-alone systems into one and drive operational efficiencies. With the deployment, Zebra identified opportunities in its North American distribution center to enhance operations.

“With our Oracle implementation we improved our operational efficiency and capabilities from a business process perspective, but we still lacked visibility into the actual actions taking place in our warehouse,” said Ashley Ford, Vice President & General Manager – North America.

With the move to Oracle, Zebra had to change its process for consolidating orders. When pickers move products from the warehouse to staging areas, they often need to combine items with other picked goods before they are ready for shipment. Items remain in a staging area until the entire order is complete.

However, in Oracle, orders are “blind” to the size of the area required for staging. At times, they would relocate an order multiple times before it was complete and pickers frequently had to search through products already in the staging area to complete an order.

“It was very difficult to locate individual items to pair up orders,” said Daniel Larkin, Warehouse Control Board Manager. “It was taking one to two minutes to find where to put the material we had just picked.”

Pairing reconfigured products with the rest of orders presented another challenge. Reconfigurations refer to customizations of printers and other accessories for specific customer needs.

Team members would stage completed reconfigurations in the aisles until the finished goods were moved to the shipping area. Yet, they had no way to notify the shipping staff when it was time to remove items from the aisle. Goods accumulated in the narrow aisles, blocking picking, creating a safety hazard, and slowing order completion by up to 15 minutes – several times a day.

The Solution

Real-Time, Accurate Data for Staging Orders.

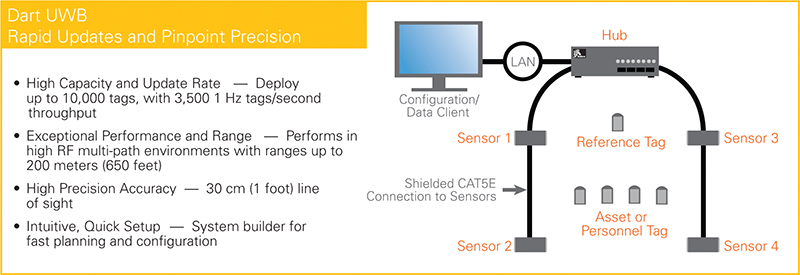

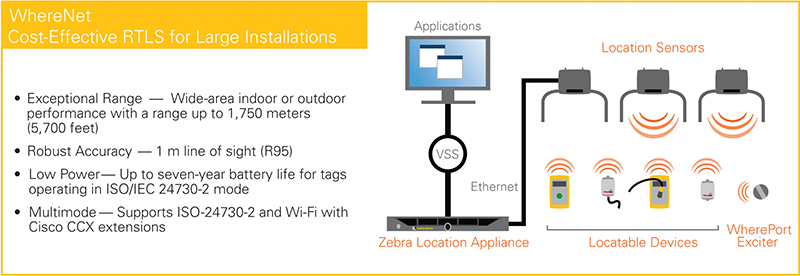

Zebra turned to its own real-time locating systems (RTLS) technology to improve communication and efficiency at the Vernon Hills distribution center. RTLS provides precise positioning solutions with active RFID for real-time identification and tracking of objects and people. Already, the warehouse had the Zebra WhereNet ISO/24730-2 and Ultra Wideband (UWB) infrastructure in place.

To improve communication regarding staging areas, Zebra leveraged its Dart Ultra-Wideband (UWB) RTLS hardware and Visibility Server Software (VSS). The warehouse assigns a DartTag to each order and places it in a staging area. Oracle specifies the staging location associated with a UWB tag where pickers should deliver items for a specific order.

To find each staging area, pickers consult one of several large monitors placed strategically throughout the warehouse or handheld devices and bring items to the right location. They now move orders to the most appropriate location in the warehouse without concern over whether others will find it. Once an order is complete, the DartTag is sent to a new zone in preparation for the next order.

“We can have multiple people looking for different locators,” Larkin said. “The map displays the exact location of UWB locators to an accuracy of a foot on the screen.”

To relieve congestion associated with reconfigurations, the warehouse added Zebra WhereCall wireless call and messaging tags in the reconfiguration/kitting staging areas. When it’s time to move completed orders for shipping, reconfiguration team members simply press the buttons that alert material handlers via a pager that items are ready for pickup. If orders are not cleared within a designated timeframe, a second escalation message is sent to a shift supervisor, ensuring fast response. After material handlers retrieve items, they turn the WhereCall tag off.

“The technology makes visibility possible with live data from tags associated with orders and material handling equipment in the warehouse,” Ford said. “This means our personnel on the warehouse floor have better information to process orders.”

Results

‘Fantastic Leap’ in Efficiency

RTLS immediately improved communication, efficiency and safety at the Vernon Hills warehouse. “We rolled out the locating system here, and the difference was astonishing,” Larkin said.

Now, all team members involved in assembling an order know where to bring items and when the order is complete, saving three minutes on total order search and staging times. Reconfigured items no longer linger in the aisles, decreasing congestion and safety concerns. With the dynamic staging process, Zebra achieved a 40 percent space savings reduction. All this helps orders move along to shipping and out the door faster.

Distribution center efficiency ultimately results in happier partners and customers. Plus, Zebra now has a way to measure its reconfiguration and warehouse processes to determine how to improve them in the future.

“The capability of knowing where things are at any particular time eliminates search time and locating challenges in everyday tasks,” Ford added. “With the location solutions technology, we’ve turned the lights on in terms of the visibility in our warehouse. In a nutshell, the system has improved our warehouse throughput by reducing order search and staging times, so much so that we are now extending it to our warehouse in the Netherlands. It’s been a fantastic leap from previous methods.”

Article Topics

Zebra Technologies News & Resources

Data Capture: Bar coding’s new companions Zebra Technologies introduces wearable computers Data Capture: Bar coding’s new friends Retail distribution closes in on the customer Enhance Your 3PL Operations in 2024 with the Latest Technology Solutions Automatic data capture (ADC): Accelerating the process Van Meter: Saving space while increasing throughput More Zebra TechnologiesLatest in Technology

South Korea Finally Overtakes China in Goods Exported to U.S. SAP Unveils New AI-Driven Supply Chain Innovations U.S. Manufacturing is Growing but Employment Not Keeping Pace The Two Most Important Factors in Last-Mile Delivery Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds More Technology