The Four Must-Haves of S&OP

Even though enterprises have been implementing sales and operations planning (S&OP) programs to better anticipate and synchronize supply and demand for more than 30 years, the success of such initiatives still eludes many.

Though S&OP success has proven to be difficult to achieve, executives still recognize its importance.

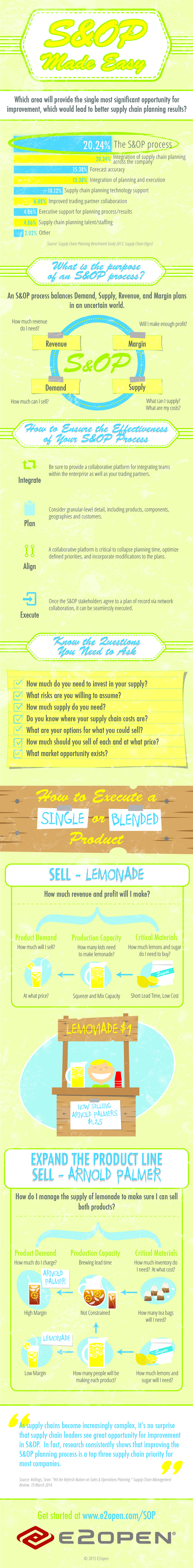

In fact, in a recent study that I read, business leaders viewed the S&OP process and the integration of supply chain planning across the enterprise as the top two areas of improvement to attain better supply chain results.

So, given S&OP’s long-standing history in supply chain operations and its recognized importance among executives, just why has it been so difficult to successfully implement an S&OP program?

For one thing, the goals of S&OP have evolved. S&OP was initially meant to get different stakeholders of an enterprise on the same page, which is still key.

However, based on what I’ve seen in today’s marketplace, the new normal is the timely and systemic involvement of the trading partners (e.g., distributors, customers, logistics providers, contract manufacturers, suppliers) in this process. Bringing them into the fold is a must, as they directly impact the ability to achieve the operational, commercial, and (ultimately) the financial plan.

Yet, as I’m sure we’ve all noticed, with today’s incredibly complex supply chains, this has proven to be quite the feat. Globalization has been a driver of this complexity, with outsourced manufacturing and distribution leading to information fragmentation and overload. In addition, demand is volatile, product lifecycles are shrinking, and product variation has complicated the elements of supply, making forecasting and planning more difficult.

Further compounding the issue is the fact that spreadsheets continue to be the method of choice for managing demand and supply translation. Due to this manual process, valuable information is often lost, miscommunicated, or painfully slow as it makes its way through the enterprise to various stakeholders in one-to-one communications. As a result, information gets out of sync, and key S&OP participants simply aren’t on the same page.

To help businesses overcome these multiple roadblocks, E2open recently released a white paper, “Commit with Confidence: The Four Must-Haves of S&OP,” outlining the four essential steps to succeeding in S&OP:

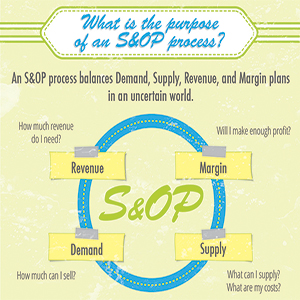

Integrate. S&OP is really about people collaborating to execute and course-correct plans to achieve departmental, corporate, and trading partner goals, as opposed to simply automating a process with technology. However, it’s important to recognize that most companies have an S&OP process that is either immature or does not yet exist. With that in mind, be sure to provide a collaborative platform for integrating teams within the enterprise, including supply chain or operations, commercial (typically sales and marketing), finance, and executives, as well as your trading partners (i.e., manufacturers and distributors on the supply side, and distributors and customers on the demand side).

Plan. Organizations should enable planning for demand-driven supply optimization with the unique ability to match granular demand with granular, often constrained, supply and capacity. The demand plan is important to S&OP, but to get the most value out of it, the plan should consider granular-level detail, including products, components, geographies and customers. Next, think about your customer priorities. Does your demand plan translate product SKUs to component part numbers on the supply plan? Can you commit with confidence at this level of demand/supply matching?

Align. In my experience, one of the greatest challenges of getting S&OP to work is gaining agreement among stakeholders. As a result, this triggers a series of additional actions, including testing the feasibility of the proposed plans and modifying those plans collaboratively in a timely fashion. However, because of the time lag associated with manual, serial sharing and analysis, the process can often take so much time that another S&OP meeting arrives before plans from the previous one are vetted and executed. A collaborative platform is critical to collapse planning time, optimize on defined priorities, and incorporate modifications to the plans.

- Execute. Once the S&OP stakeholders agree to a plan of record via network collaboration, it can be seamlessly executed, meaning no more swivel chair, manual movement of plans among systems with the inherent errors and latency of data transfer and entry. But you’re not done quite yet. As a further opportunity, be sure to go beyond the role of “system of process” to enable the integration and updating of plans in the typically standard system of record: ERP. Now the operational, financial, and commercial plans can be in sync so that all teams work together to achieve common, corporate objectives.

In short, S&OP teams need information that is comprehensive, timely, and trustworthy. With collaboration and evaluation tools embedded throughout the process, stakeholders are able to commit with confidence to their operational, financial, and commercial plans for S&OP success.

Article Topics

E2open News & Resources

E2open President and CEO Farlekas Provides Logistics Trends and Themes Overview E2open Transportation Management Solution to Simplify Your Logistics Supply Chain Disruptions and the Next Normal for Logistics in 2023 Outsourced Quality and Sustainable Manufacturing in a World of Disruption Mitigating Supply Chain Disruption in the Wake of Severe Weather and Disasters Uber Freight & E2open to Provide Real-time Transportation Rate and Capacity Options Tracking and Reducing Transportation Emissions More E2openLatest in Supply Chain

Ask an Expert: How Shippers Can Prep for Hurricane Season Apple Accused of Multiple Human Rights Violations South Korea Finally Overtakes China in Goods Exported to U.S. UPS Struggles in First Quarter With Steep Earnings Decline How Supply Chains Are Solving Severe Workplace Shortages SAP Unveils New AI-Driven Supply Chain Innovations How Much Extra Will Consumers Pay for Sustainable Packaging? More Supply Chain