Five “Must-Have” Attributes of a Smart Warehouse

Enormous improvements in technology combined with operational enhancements have allowed facilities of all sizes to become what we call “Smart Warehouses.”

So what is a Smart Warehouse?

If we compare it to a “smart phone” or “smart appliance,” one may conclude that only the most highly automated facilities using robotics and being run by computers are considered “smart.”

While automated picking, loading and replenishment systems are indeed smart by today’s standards, this paper contemplates a more familiar warehouse operation scenario based on countless feedback from warehouse operators.

In this scenario, we define a Smart Warehouse as one that operates as efficiently as possible, always with an eye to best practices, under ever changing demands and within the budget constraints put on by the business itself.

These Key Attributes are “size neutral” and apply to anyone running a warehouse or distribution center that needs to stay responsive and competitive – no matter what the budget.

Our five Key Attributes include:

1. Automate - Pick off the Low Hanging Fruit

Perhaps the single most important factor is process automation. Smart Warehouses work to eliminate the use of manual labor and input wherever possible. In addition to helping reduce costs and manpower needs, process automation can increase shipping accuracy and the speed in which data is input, no matter what level of volume is being processed.

Effective automation requires a certain amount of consistency both in repetition and product throughput. And, of course, the more consistency and repetition in the business, the more justification for more sophisticated automation. Without either, however, the cost of hardware and/or software may not justify the expense.

So, how does a Smart Warehouse measure when and how much to automate?

While each Smart Warehouse needs to determine their own Internal Rate Of Return (IRR), we have observed a general rule of thumb that the labor savings from automation should exceed the automation costs by 2 to 1 within 24 months to justify the investment.

That said, a longer payback may be justified for more homogeneous or static products. And, also, it is important to remember to factor in maintenance and upgrades as hardware breaks and software may come with added costs.

If you’re not ready for a big investment in automation, the good news is that the technology of today takes care of a lot of the “low-hanging fruit” at an extremely affordable cost. On the business process side, software provides for Automatic notifications for virtually every step in the process flow - from Advanced Shipment Notifications (ASNs), to automated process execution, automated packing slips and more.

If you are a 3PL warehouse, automated billing is a key feature, allowing the 3PL to fully capture all the services provided.

In the area of customer service and satisfaction, automated email alerts foster an effective communication channel with the customer at every stage. Not only will communications be faster and more efficient, they can also be tailored on an individual customer level, further increasing customer satisfaction levels, without adding to any bottom-line costs.

With regard to simple hardware automation, mobile barcode scanners, wireless printers and other handheld devices are now priced in an incredibly competitive market, with new or refurbished products being within reach of many operations.

Optimizing Strategies for 3PL Warehouse Operators

Warehouse operators are continually looking for ways to stay competitive in today’s 3PL Central market. Analyzing system data at the warehouse level to support strategic decisions and improve customer service can help the operator make strides in operational efficiencies.

With a fully functioning warehouse management system, the 3PL warehouse operator should be able to look for trends in inventory both as to type of inventory as well as across 3PL customers and use those trends to serve their customers better. The key to identifying trends in inventory is based on the ability to compile and associate warehouse data so that it can be evaluated and understood and then ultimately delivered through effective reporting.

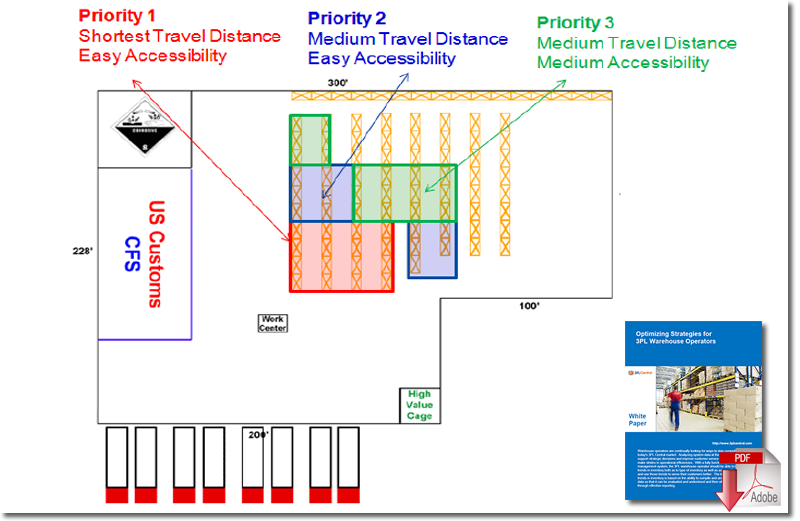

Warehouse Location Attributes: Allocation Priorities

Setting allocation priorities through location attributes and then segmenting data into groups helps integrate velocity picking and replenishment rules. The below image illustrates an example of three allocation priority groups from a racked storage location. In reality there could be hundreds of allocation priorities.

The intention is to put the fastest moving product in the top priority location. This will provide for the least travel and most efficient picking. The allocation priority should focus on:

- Leveraging allocation priorities for replenishment

- Assigning non-priority locations to serve as bulk storage

- Evaluating warehouse setup to determine priority locations

2. Be Nimble

The second attribute of a Smart Warehouse is to stay nimble - or at least as nimble as possible. As noted above, the higher level of consistent throughput and processes may dictate a larger investment in “fixed” automation, so there may be a tradeoff to some degree, and some loss of nimbleness as the investment in fixed automation goes up.

Notwithstanding, there are base areas in any warehouse operation that require ongoing management - to manage the business at hand, and the business that is soon to come. This can include everything from managing the physical environment, to staffing needs - to on-the-fly upgrades to software and management systems.

A Smart Warehouse has two essential tasks with regard to the physical warehouse – the first is to optimize the warehouse as it exists, and the second is to manage and plan for future growth. In optimizing the space, reconfigurable racking and pick shelves are often used so they can be changed out quickly in response to new products or needs.

The Smart Warehouse will also have flexible or alternative process flows that allow “all” goods to move seamlessly from dock to shelf, dock to work areas, dock to dock etc. efficiently. These processes should be documented and segregated for each product line to minimize disruption and maximize efficiency. For future growth, smart warehouse operators pay keen attention to their relationships with commercial brokers for temporary space, as well as nearby (or key area) 3PL operators for overflow or outsourcing specific product lines.

On the personnel side, Smart Warehouses need to have a strategy to staff up or down as business demands. One general rule of thumb that we have observed is that the Smart Warehouse employs a core fixed staff of versatile and cross trained professionals. This core group is generally sized to be sufficient to operate the warehouse at the third slowest month of the year.

From a planning perspective, this leaves the two slowest months for full time employees to take vacations, consider professional development training and other personal time. In busier months, established relationships with staffing agencies become a critical source of additional labor as the business grows. Fostering good relationships with reputable agencies ensures that candidates are properly screened and suited for the requirements of the job.

In addition to providing work, these additional employees also become part of the core group and are incorporated into the permanent framework of the business as part of the growth cycle.

With regard to software, staying nimble means employing a robust and customizable WMS that can handle the extraordinary range of platforms, sales systems and protocols with which it may interface. This can include everything from back-end CRM systems, to eCommerce programs - to such widely used and efficient communication technologies like EDI. Unlike the expensive deployed systems of old, the SAAS, on demand alternatives of today provide an abundance of nimbleness.

These on demand software packages are typically priced at affordable price points, often require subscriptions of one year or less, and have enormous flexibility to grow as the business grows.

Long story short – Smart Warehouses are now expected to perform flawlessly in today’s highspeed and ever-changing business environment. They must therefore secure the space, assemble the team, acquire the system and purchase the tools that will enable this level of execution from the start and allow them to move with the speed of business and remain profitable.

3. Make Sure You’re Ready to Scale

The Smart Warehouse is always asking the question, “Can We Scale?” In essence, a Smart Warehouse should be built to handle rapid changes in demand. And a Smart Warehouse is always positioning itself to scale, by having all the tools in place to attract and retain customers, and support new product releases. When all the basic operational requirements are in place, scalability is often dependent on the warehouse management software chosen.

When properly designed, a Smart Warehouse can be ready to handle new surges in growth or responsibility without missing a beat – or breaking a budget.

Modern Software as a Service (SaaS) WMS offerings are a particularly attractive option in this case, as they can provide access to new features quickly – usually without the need for new hardware purchases, consulting fees – or involvement from the IT department. This helps to minimize set-up and take down.

As noted, entry price points, particularly given the feature-rich nature of the basic software, are extremely reasonable. Even more importantly, modern SAAS offerings are so affordable, that they can be used to attract customers. Unlike the old expensive deployed systems in which the customer had to come before the system, the on-demand WMS can be used as a tool to attract customers and become an important part of the warehouse sales process.

4. Operating In Real-Time Is the New Standard

A Smart Warehouse is expected to be fully integrated, fully transparent – and fully capable of providing their customers and stakeholders information about their inventory – as soon as it is handled. Visibility and Real Time are the basic standards of any Smart Warehouse. And, for the 3PL operator, if your 3PL warehouse cannot demonstrate that capability, you can be sure that your competitors can and will.

For the Smart Warehouse, this means that information is updated as soon as tasks are completed – as opposed to waiting to process overnight. This allows the warehouse customer full visibility into the system so they can see the status of their inventory as it exists at the moment, as opposed to last night, or even two hours earlier.

Because Real-Time is the new standard, software and data collection devices such as handheld barcode scanners are an excellent tool to keep inventory levels accurate and up-to-date. It is just as important that Smart Warehouse personnel adopt a collaborative mindset where their customers, clients and other employees are viewed as partners with whom information should be shared freely.

The Smart Warehouse heralds the beginning of a new age of transparency, visibility and teamwork.

5. Web Centric is Customer Centric

And finally, a Smart Warehouse builds its business to provide for a Customer Centric experience, and a Web Centric approach is the perfect facilitator.

The advantages of the web in terms of delivering a 360 degree customer experience, fostered by competitive and affordable pricing, delivery of a superior warehouse and distribution service, and enabled by a WMS that is extremely robust, is a value proposition that is hard to ignore. In fact, cities around the country are already being “wired’ for the next evolution in the internet that will process data 10 times faster than the fastest connection today.

What’s more, web-centric systems allow the Smart Warehouse to access its operations 24 hours a day, 7 days a week, from anywhere in the world and on all types of devices. And, of course, this same benefit runs to their customers, partners and stakeholders.

With the proliferation of all things “Smart” and increasing availability of Wi-Fi access, this is a trend that will certainly continue to grow. Indeed, many experts are already anticipating the coming “Internet of Everything” – wherein every device, every system – and even the very inventory on their shelves – will be able to communicate with one another.

Summary

In short, the Smart Warehouse must be able to:

- Automate as it makes sense economically, but don’t ignore the easy stuff. There is a lot of automation available here and now without any significant investment.

- Remain nimble in terms of space, staff and software

- Scale instantaneously in response to need

- Provide 100% Visibility – in Real-Time

- Use a Web Centric approach to run the business and provide a Customer Centric experience