Study Highlights Pressing Need To Evolve Manufacturing Risk Management

Improved risk assessment provides greater agility and greater protection against disruptive and potentially catastrophic events that characterize prolonged periods of decline - the manufacturer becomes more agile and able to recognize and respond to such events, and to capitalize on the opportunities such events reveal.

This study, jointly conducted by Deloitte and MAPI, looks at how manufacturing companies are assessing and responding to risks today and in the future.

It finds that the current operating environment demands a more analytical, agile, and clinical view of risk to effectively address the complexity and velocity of critical risks and disruptions to their businesses.

“The pace and impact of innovation, coupled with cybersecurity risk, creates a risk environment that must be carefully managed,” said Brian Clark, partner, Deloitte & Touche LLP, and co-author of the study.

“Product innovation can rapidly make existing products obsolete, potentially delivering considerable value to the innovator while leaving the unprepared facing competitive disadvantages.

Further, technological innovation enables the manufacturing business model more, but can present a strategic risk as well. For manufacturers to thrive amid the ever-changing risk landscape, a company’s risk assessment practices should align with those changes.”

Unique Risk Aspects Manufacturers Should Consider

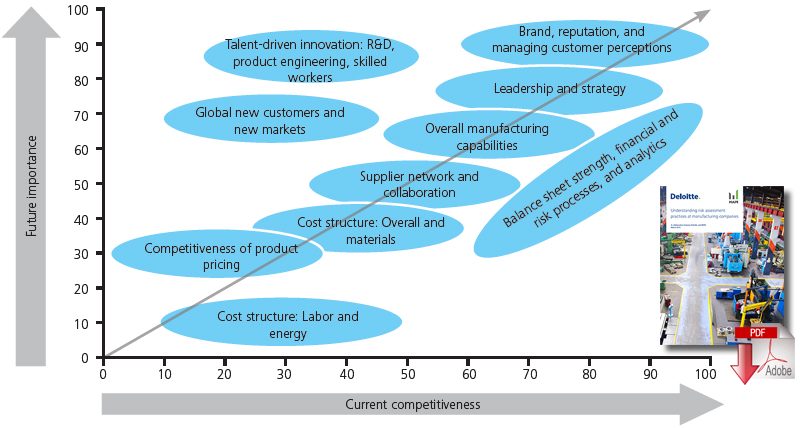

Defining what characteristics can set a company apart competitively - today and in the future - is critically important for risk management. Survey respondents ranked competitiveness drivers such as innovation and talent management as priority business risks, indicating leading practices in these areas may set a company apart.

Additionally, risk management and data analytics - areas where internal audit and risk executives are making significant investments - were also classified as competitiveness capabilities.

Supply chains are highly complex and continuously exposed to a variety of internal and external risks, and, if not managed carefully, can result in potential adverse impacts to manufacturers’ sales and brand reputations.

The study indicates manufacturers should build resiliency into supply chains to address critical vulnerabilities proactively, as well as balance risk and costs to prevent or recover quickly from risk-related disruptions.

Implications of the skills gap in manufacturing can also pose a material impact on manufacturers’ growth and profitability. Internal audit can play a key strategic role in assessing programs - such as recruiting and retention initiatives, HR IT systems, and deployment of data analytics capabilities to monitor trends - designed to mitigate the anticipated talent shortage and skills gap risks.

Can Today’s Risk Assessment Techniques Assess Tomorrow’s Top Risks?

Survey respondents indicated a variety of successful and ineffective assessment practices.

Successful practices include:

- interviews;

- periodic presentation of specific risk topics to the board committee tasked with governance; and

- integrating risk assessments into the strategic planning process with business units.

Least-effective practices include:

- risk questionnaires or surveys that are too long or sent to too many people;

- accepting canned or repetitive risk mitigation responses; and

- risk assessments that are too narrowly focused.

Defining Characteristics - Clusters of Capabilities - of Current and Future Competitiveness Capabilities

Graphic: Deloitte University Press | DUPress.com

Related: Supply Chain IT Risk Mitigation Still Work in Progress

Article Topics

Deloitte News & Resources

MHI Report: Investment increases as supply chains become more tech-forward and human-centric Global Trade Tensions, Material Shortages Not Expected to Ease in 2024 Blockchain in Supply Chain Continues to Mature Supply Chains Struggle to Access Reliable Emissions Data from Suppliers State of the industry: MHI releases annual report at ProMat 2023 MHI and Deloitte launch 2023 Annual Industry Report survey How Amazon Is Preparing For Fully-Electric Drone Delivery More DeloitteLatest in Supply Chain

Happy Returns Partners With Shein and Forever 21 to Simplify Returns Baltimore Opens 45-Foot Deep Channel Following Bridge Collapse El Paso Border Delays Cost Juarez $32 Million Per Day in Economic Losses Ranking the World’s 10 Biggest Supply Chains The Top 10 Risks Facing Supply Chain Professionals Walmart’s Latest Service: Ultra Late-Night Delivery Dollar Tree’s Oklahoma Distribution Center Decimated by Tornado More Supply Chain