STORD to Build Fulfillment Center in Atlanta Using Locus Robotics

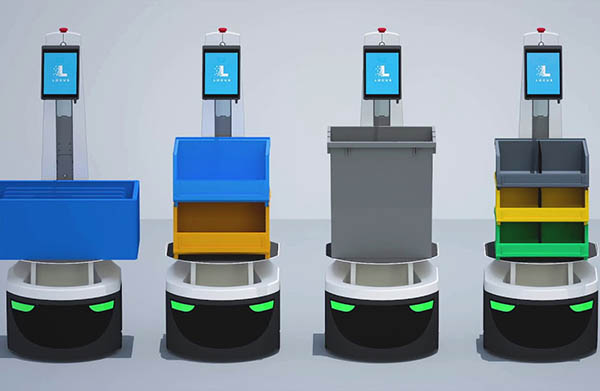

Locus mobile robots to be integrated with STORD's cloud platform in a new facility to meet growing logistics demands.

STORD Inc. today announced that it is building a warehouse and fulfillment center that will integrate technology from Locus Robotics. The Atlanta-based company said it expects the 386,000-sq.-ft. facility to provide additional logistics capacity for its customers and bring hundreds of jobs to the area over the next two years.

Global e-commerce could reach $5 trillion this year, and business-to-business (B2B) online commerce is projected to reach $20.9 trillion by 2027. Analysts predict that the warehouse market will reach $625 billion by 2025, with the same-day delivery market growing to $20 billion by 2027.

Founded in 2015, STORD's provides shipping visibility, on-demand scale, and a unified logistics network to more than 500 companies. The company raised $65 million in Series C funding in March and said it is growing revenue 300% year over year.

Sean Henry, co-founder and CEO of STORD, replied to the following questions from Robotics 24/7 about his company's partnership with Wilmington, Mass.-based Locus Robotics.

In terms of the e-commerce surge, what challenges are your customers currently facing?

Henry: Our customers are telling us that today's supply chain and software tools haven't evolved sufficiently to meet the needs of consumers expecting Amazon Prime-type rapid service or the complex needs of B2B businesses. Companies rely on a patchwork of disconnected 3PLs [third-party logistics providers], creating a logistics network that is inflexible, expensive, and opaque. The result is slower packages, higher prices, and unhappy customers.

STORD is leveling the playing field. We are the cloud supply chain for companies that urgently need world-class logistics. Leading B2B and B2C companies like Body Armor, Advance Auto Parts, and Dollar General use STORD to transform their supply chains to operate with the speed, flexibility, and ease of the cloud.

Built by experts from Amazon, XPO, Coyote Logistics, Convoy, and Ryder, STORD provides businesses with access to end-to-end logistics—including warehousing, freight, and fulfillment—via a single, integrated platform that's available whenever and wherever companies need it.

Why did STORD pick Locus Robotics out of all the mobile robot suppliers out there?

Henry: First and foremost, we chose Locus because we found them to be the best product and best partner for our needs. Locus offers superior flexibility, high productivity, and seamless scalability. Their bots work nicely in combination with human associates and work with a diverse set of pick methodologies.

We found their mindset and business model to be very complementary to ours in that they are building solutions to future-proof supply chains and adapt to the demands of modern business. Locus’ ability to move quickly and their flexibility in scaling were key factors in our decision to partner.

How much work was required to integrate STORD's software with that of Locus Robotics?

Henry: Thankfully, this part of the process is one that we haven’t had to worry about. Both organizations have robust integration teams and significant libraries of pre-built integrations.

Given this, the integration process between STORD and Locus has been incredibly smooth, highly automated, and has not required significant manual work.

How many LocusBots will the new fulfillment center be using?

Henry: Our goal is to provide the best customer experience and develop innovative processes and strategies that we can use across our entire network. To that end, our usage of LocusBots will vary as we scale. Out of the gate, we are starting with 30 bots, but we plan to expand as we grow.

Locus Robotics specializes in robots that work with human pickers. How much training do you expect associates to need?

Henry: Associate training is part of the Locus onboarding, which our employees are undergoing now. We will be fully operational with the bots and necessary human processes by Sept. 1. Part of why we picked Locus is the ease of use for our human employees. Training typically takes just a few minutes, enabling workers to be productive almost immediately.

Because the bots can change their on-screen display to the preferred language of the worker, it helps reduce errors and helps speed up their productivity. Bots and humans can easily coexist and work together in aisles, and the system provides flexibility for a number of different pick-and-pack methodologies.

Since STORD provides on-demand capacity and Locus supplies robots as a service (RaaS), how are your business models complementary?

Henry: The complementary nature of our businesses made our decision to partner easy. Both organizations are incredibly agile and equipped for the demands of modern business. STORD offers companies the supply chain flexibility that they need to keep up with their customers. This includes quickly adding new locations, optimizing inventory routing, and adding new shipping carriers.

For us to be able to do this, we need to partner with providers that can operate with a similar level of agility. Locus was a perfect fit due to their ability to move quickly and scale up as needed, whether that be adding new bots to existing facilities or deploying bots to new facilities, often in just weeks.

In addition, Locus’ performance dashboards and reporting capabilities allow us to monitor productivity and manage workflows in real time, right in the warehouse.

Are you designing anything differently, since you have robots in mind, such as more networking? Or is the facility still mostly human-focused?

Henry: A major reason for opening this facility is to fuel further innovation so we can hone our practices for optimal efficiency across our network of hundreds of facilities. To that end, we will be testing several different uses of the bots and several different methodologies for fulfillment.

We are investing heavily in our network infrastructure within this new facility to support both robotics and other innovations and automation. We see the network investment as the showcase for how STORD develops and supports innovation.

When will the new facility be complete?

Henry: We are in the late stages of completion for the space now, and the facility will officially open and be ready for customers in September.

Article Topics

Locus Robotics News & Resources

Autonomous mobile robots (AMRs) on a mission to automate Transforming Warehousing with AI: Five Key Reasons to Adopt Now Maximize Warehouse Space with Mezzanine Automation: Expert Tips Autonomous mobile robots (AMRs) on a mission Up close and personal with mind twisting special purpose robots Locus Robotics Unveils New Warehouse Optimization Tool Locus Robotics showcases warehouse fulfillment and automation innovations More Locus RoboticsLatest in Supply Chain

C-Suite Executives Investing Heavily in Generative AI Trucking Industry Pushes Back on Government’s Electric Mandates Senators Take Aim at Amazon with Warehouse Worker Protection Act Maersk Sees Silver Lining in Red Sea Shipping Challenges Happy Returns Partners With Shein and Forever 21 to Simplify Returns S&P Global Market Intelligence’s Rogers assesses 2024 import landscape Frictionless Videocast: AI and Digital Supply Chains with SAP’s Darcy MacClaren More Supply ChainAbout the Author