If it’s Not Real Time Data, It’s Old Data

If you run reports on yesterday’s manually collected data, then you will only have information about yesterday.

We have so much real-time data around us in our daily routines.

A barista starts to prepare my order the moment that I purchase my daily coffee.

I instantly know how close I am to the speed limit thanks to my car’s speedometer.

And I see an accurate count down of the number of minutes before my computer turns off due to a drained battery.

Since all of this real-time data is available in our day-to-day lives, shouldn’t we expect the same for data we use in our manufacturing organizations?

Countless times I have walked into customer sites on Day 1 and seen old data everywhere.

I have seen four walls of a conference room covered with 8 ½” by 11” printed reports, most of which were multiple weeks old.

Or users that explain that they perform analysis based off of desktop spreadsheet files, with manual data loads. In each of these cases, people are operating off of old data, even if it was updated just a few hours ago.

If my speedometer had that same delay, I would have a lot more speeding tickets!

Old Data is Just… Old Data

Manufacturers today are asking themselves how they can do better and be better. They realize that to be competitive, they should look inside the factory first and explore their own processes to find areas for improvement.

If they analyze their data to see what it shows about their operations, they tend think that any data to go off of is better than no data, right? Not always, I say.

Based on how fast your environment changes, it could be detrimental to make decisions off of old data. Since the pace of business has increased for manufacturers, thanks to both technology and complexity, so too should the pace at which data is collected and made available to make informed decisions.

For example, consider everything that can happen in the span of an hour:

- Purchasing finds out that a truck shipment of raw materials will be delayed two days due to weather.

- A new customer puts in a rush online order double the size of previous months.

- Maintenance begins fixing a problem on a constraint resource that is estimated to take at least a couple of hours.

Wouldn’t your organization want to know about all of these situations as soon as it could? Certainly. Keep in mind, however, that as more and more data is available, you’ll need to discern if, when, and how you take action. That is, you’ll need to separate knowing that events occur versus reacting to them right away.

Each event could immediately impact your organization’s priorities, but you also don’t want to be jumpy and let every event disrupt your overall process. The important thing is that you are aware and that you have the right information at hand to make necessary decisions.

Better yet, your systems can also be aware of this same event data and alert you only to the issues that require your intervention. Technology solutions for manufacturers should be able to take real-time data, assess it against other conditions and values, and then notify you to respond only to the events that need your attention.

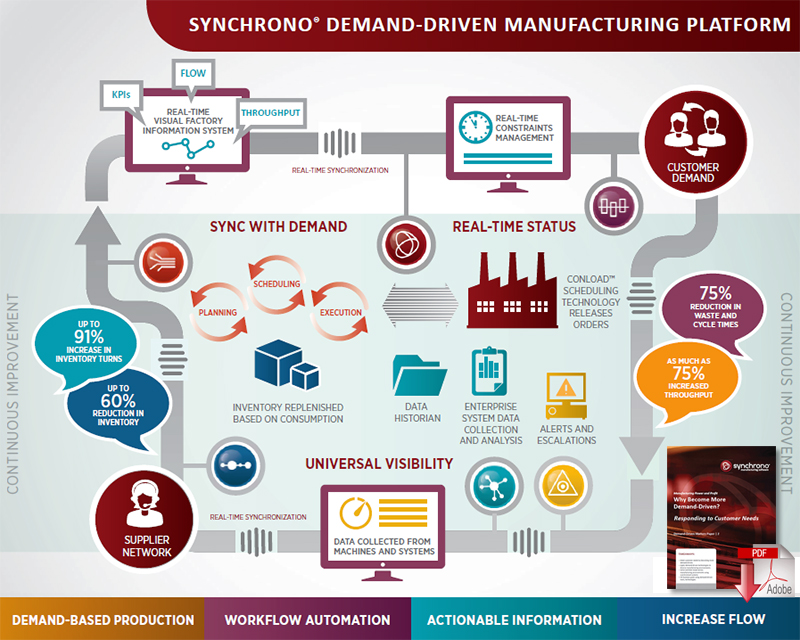

This is the nature of demand-driven manufacturing - since the focus is on overall production flow, you only need to address those issues that disrupt flow. The rest is probably just normal “noise” - or what becomes a normal day for a manufacturer.

Manual Reporting Makes Data Stale

So how did we get to the point where so many manufacturers are not using real-time information? Thankfully, manufacturing technology is catching up to provide all of the information and analytics that companies seek in an automated, real-time manner. Organizations have always had the desire for information and reports, but they’ve commonly only had manual methods as options.

Consider the volume of reporting that a typical manufacturing company does on a recurring basis - that’s a lot of manual reporting happening based on non-real time data. Think of the time drain that both the manual data collection and report running put on a company. If it takes an analyst only two hours to run a report, that means they are already using information that’s at least two hours old.

If you run reports on yesterday’s manually collected data, then you will only have information about yesterday. Further, we will still need a clear, straightforward way to display that information to users. I know my car’s current speed based on the easy-to-read dashboard, for example.

If we demand that our organizations collect real-time data – and we have a tool like a visual factory system to display this information - then we have a powerful platform from which to understand what is happening today and what to prepare for tomorrow within operations.

Related White Papers & Guides

Common Barriers to Moving from Push to Pull Manufacturing

Lean manufacturers continue to address throughput issues by automating systems and creating better processes to eliminate waste in all of its forms. Download Now!

The Next Generation of Planning and Scheduling Solutions

The primary goal of most manufacturers has remained constant over the last 50 years: make money now and into the future, yet the underlying process and objectives to achieve this goal have changed considerably. Download Now!

Manufacturing Metrics that Drive Action

As more manufacturers evolve toward a demand-driven (or customer centric) method of manufacturing, the metrics that measure their success change. Download Now!

Demand-Driven Manufacturing Metrics

Operational metrics that drive action in Demand-Driven Manufacturing environments. Learn more about the Metrics for Action by downloading the Guide. Download Now!

Gaining Control: Exploring Push v. Pull Manufacturing

If you’re considering a shift from a traditional, push-based MRP manufacturing system to a more progressive pull-based system, this white paper is a must read. Download Now!

Gaining Clarity: Drive Productivity, Flow and Profit with Data that Matters

Many of today’s discrete manufacturers are overcoming the challenges of legacy push-based systems by turning to pull-based eKanban systems that focus on throughput and flow and result in a reduction in costs and inventory. Download Now!

Gaining Confidence: Syncing Supplier Delivery to Customer Demand

Demand-driven and lean production allows manufacturers to be more responsive to consumer needs while increasing their own profitability, it also reduces the reliance on forecasts by linking demand signals and providing real-time data directly to suppliers. Download Now!

Gain a Competitive Advantage for Bottom-Line Results

Modern manufacturing is using automation and technology in new and ever changing ways, significant competitive advantage is gained through these advancements. Download Now!

Why Become More Demand-Driven?

In this paper, we will examine the nuts and bolts of “common” manufacturing environments and look at how software solutions help harmonize these processes using improved data, visibility and demand-driven practices. Download Now!

Article Topics

Synchrono News & Resources

Strategies for Managing Manufacturing Bottlenecks and Constraints Eliminate Production Bottlenecks; Manage Manufacturing Constraints Demand-Driven Manufacturing Can Help You Cost-Justify Your Next IIoT Project Technology will Connect Your Enterprise and Create the Demand-Driven Factory of the Future - Today Time for Manufacturers to Cut Ties with MRP and Spreadsheets How SyncKanban eKanban Software Addresses Lean’s 8 Forms of Manufacturing Waste The 8 Forms of Waste in Lean Manufacturing More SynchronoLatest in Technology

South Korea Finally Overtakes China in Goods Exported to U.S. SAP Unveils New AI-Driven Supply Chain Innovations U.S. Manufacturing is Growing but Employment Not Keeping Pace The Two Most Important Factors in Last-Mile Delivery Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds More Technology