How to Embrace the New Normal for Demand Planning

One thing that has caught the world of supply chain entirely unawares during this global pandemic is demand volatility.

In the duration of the last four months we have seen demand patterns ranging from huge spikes, deep troughs and everything imaginable in between.

Suddenly, what were once out of the box planning tools have now become entirely defunct because they continue to rely heavily on historical trends.

A side-effect of this situation is that many companies which relied heavily on statistical forecasts are not being able to find an alternative approach to demand planning in such a short time.

Excel based planning has once again assumed a centerstage as planners try to adjust forecast based on regional, local trends to the best of the information and tools available to them.

Not surprisingly, one of the biggest outcomes of this pandemic is that business conversations have lately become – a lot more ‘customer centric.’

And all the basic assumptions around customer consumption behavior are now being challenged every day. This has prompted many planning organizations to go back to fundamentals and re-think and re-jig their demand planning processes.

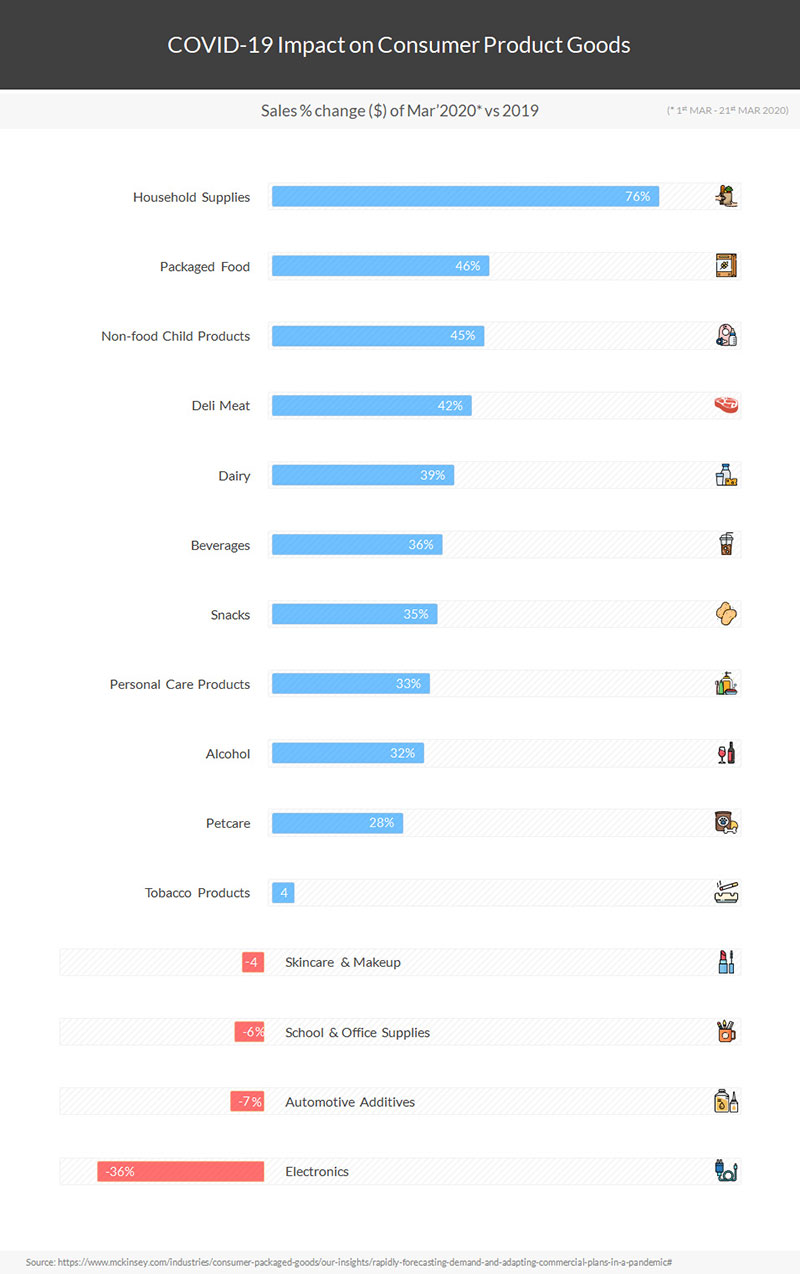

To do an overhaul of the planning process, it is imperative that we first understand the impact of COVID-19 on consumption patterns.

- Consumers are not buying few things any more… at all for instance new cars.

- Consumers are buying fewer of some things i.e. things like makeup and grooming products

- Consumers are buying more of some things and consuming them at a faster rate for e.g. cleaning supplies

- Consumers bought more of a few things and just hoarded them e.g packaged food, essentials etc.

This raises a more important question – how long will these consumption patterns last? If the answer is anything between 0-6 months, then it is essential to relook at the planning solutions.

- Start by asking if your traditional statistical forecasts are enough?

- Or, if the current systems allow you to expand features and capabilities beyond the norm?

Organizations which invested deeply in intelligent tools that not just focus on statistical forecasts but also consider the environmental variables to drive planning have survived and managed demand volatility better. And there is data to prove that:

~40% increase in forecast accuracy

~10% reduction in operational costs

~20% reduction in overstock

So, what does this mean for you, and what does the forecast in today’s scenario look like?

1. Visibility into true volatility

Visibility into end customer demand has become most significant during these times. This means getting access to PoS (Point of Sales) information. If this is not feasible or economical, then the second-best option is to triangulate orders, shipments and your forecasts. The end goal is to infer volatility and while getting hands on relevant data is step one in the right direction, it is not enough.

2. Visibility is great, but now what?

Analyze it.

There are several demand sensing tools in the market that help with sharing and analyzing end customer demand data with powerful underlying platforms. These bring the power of a platform to ingest and analyze humongous amounts of data, primarily PoS. Their focus is to analyze short terms trends and infer if any changes are needed to envisaged supply plans.

Imagine that you are in the business of selling spare parts. Intuitively you know that newer cars are less likely to be sold due to shrinking spend.

Through your PoS data analysis, you are informed that a carburetor in Auto Zone is selling more by the day. In a traditional world, you would see that spike after a week or even month depending on when your systems refresh or maybe when an Auto Zone coordinator gives your supply manager a call. With demand sensing all these dependencies and delays are erased.

What you get instead, is the ease of an actionable alert which pulls you into action – you can now commission more carburetor because they seem to be selling more or start to pull in more safety stock for carburetors to beat volatility.

3. Reinforce your forecast

That environmental factors impact your forecast is a known fact. And most smart planners intuitively know which causal factors drive demand more than others. During COVID, it’s been proven that it helps to know which areas are lifting lockdown, where the economic activity is resuming, what the current employment index is etc. Yet, what planners like yourself may not accurately be able to infer is by how much.

These leading indicators could vary widely based on industry and use case, but they could directionally give a boost to the accuracy top down. Correlating the indicators with demand drivers and running scenario analysis could help you build out a few best- and worst-case scenarios.

Such an analysis once layered with your PoS volatility analysis can give you a more informed and data backed picture of true demand.

Related White Paper

Automotive Company Leveraged Machine Learning to Improve New Launch Forecast

Learn how an automotive aftermarket leader reduce forecast error from 111% to 55% in Year 1 for new product launches. Download Now!

Article Topics

Bristlecone News & Resources

Bristlecone and Aera partnership addresses “cognitive” supply chain capabilities Managing Supplier Risk in the Age of the Coronavirus How to Digitize Your Supply Chain Without Losing Your Mind How to Embrace the New Normal for Demand Planning How a Biotech Manufacturer Leveraged AI, ML, and IoT to Gain Supply Chain Visibility How Trace.ai Enhances Supply Chain Visibility Fighting Billion-Dollar Weather and Climate Disasters with Sense.ai More BristleconeLatest in Supply Chain

A Look at Baltimore’s Key Bridge Collapse—One Month Later European Parliament Passes New Law Requiring Supply Chain Accountability Baltimore Continues Bridge Recovery With Opening of New Channel How Shippers Can Prep for Hurricane Season Apple Accused of Multiple Human Rights Violations South Korea Finally Overtakes China in Goods Exported to U.S. UPS Struggles in First Quarter With Steep Earnings Decline More Supply Chain