Forklift Operators and Technicians Safety Evolution

From small adjustments to organization-wide messaging, ensuring safety amid a pandemic will take vigilance.

Modern Materials Handling spoke with Craig Brubaker, senior vice president of operations for Alta Equipment’s Industrial Group. Alta is a Hyster-Yale dealer with 41 locations across 10 states serving the Midwest, New England, New York and Florida.

How did the dialogue with customers first develop about sanitation related to lift truck operators and technicians?

Brubaker: The dialogue didn’t actually start with the customer. I feel like we had to anticipate their expectations. As a dealer, we partnered with our OEM, Hyster-Yale, and we wanted to be ahead of that as far as what the customers could expect from us when we show up at their facility.

The first thing that came to mind for us was PPE (personal protective equipment). We needed to make sure we could shield or protect their people but also protect our skilled technicians. First and foremost, like a lot of companies we went out to secure a supply of gloves and masks for employees.

The very next thought that came to mind for us was the need for sanitation products so our technicians can sanitize both before and after each repair. Sanitizing beforehand protects them and sanitizing afterward protects the operator, who can then step back into that truck confidently and comfortably.

What challenges did your customers experience as they tried to balance serving demand while effectively managing health and hygiene?

Brubaker: It evolved so quickly and I would say it was crisis mode for everybody. There’s no playbook for this. Our customers experienced the same challenges we did. How do we run our operation without people getting sick? What happens if someone gets the virus and how would we prevent it from spreading? Our goals were the same.

They did a lot of what we did and what most businesses did; you had to put processes in place for cleaning, distancing and contactless interaction. For example, one of the first things we implemented was a contactless parts pickup and drop-off. I know it sounds very simple, but it was very important.

How did you develop guidelines for operators and service technicians?

Brubaker: I need to give a lot of credit to our panel of dealers across the U.S. and Hyster-Yale, our OEM partner. We formed a task force and as a group we were able to create some best practices to keep technicians and operators safe. Part of this offering included a DIY sanitation kit for operators.

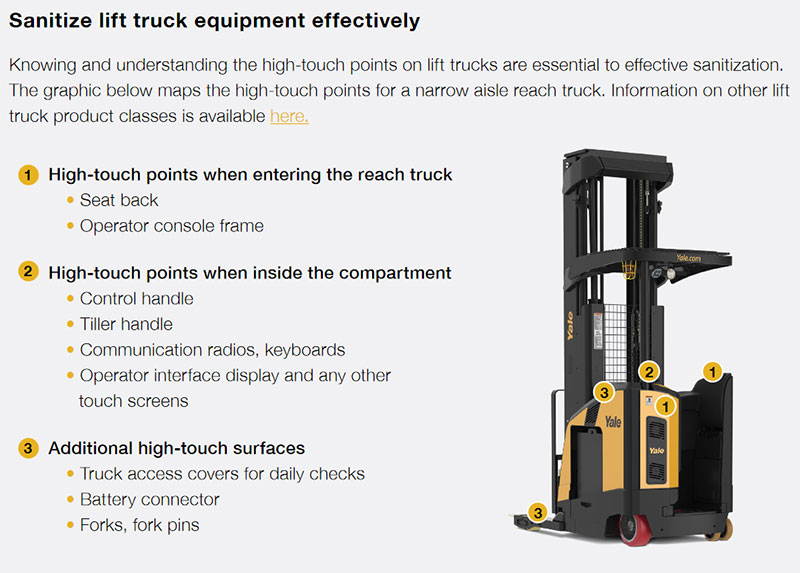

One of the most impactful things that came out of it was the cataloging of touch points for Class 1 through Class 5 equipment. What part of a lift truck is touched the most and therefore needs to be sanitized? There are the obvious, knobs and steering wheels, and there are areas you wouldn’t expect. How often does the operator touch the overhead guard, and where?

You can make a list, but people don’t tend to read lists, so it was incredibly important to turn these into visuals. A picture is worth a thousand words, so the visuals made it easy for technicians to understand what areas needed to be sanitized on each class of equipment to protect them and operators.

Knowing what you know now, what advice would you give yourself back in March?

Brubaker: Anything is possible. Expect the unexpected. We never thought we’d see another downturn like ‘08-‘09, but this has been life-changing and eye-opening for everyone. You talk about being prepared, but I think we all need to think a bit more about that and prepare for the impossible, or at least do everything we can to be ready for another situation like this.

For operations opening back up or scaling up now that states are reopening, what advice would you give them?

Brubaker: First and foremost you need to make sure your buildings are set up for when people start to return to work. We have a few buildings where we had to raise partitions between cubicles for more protection.

There are also simple things like moving chairs out of your lobby to provide enough space between guests. I think the most important thing at this point is realizing when “Covid fatigue” sets in. We can’t let our guard down. You need to enforce the social distancing and keep your people safe. It really only takes one case that could spread and shut down your business.

How will you disseminate updated guidelines as conditions change, especially since there will be differences in each state?

Brubaker: We will work with our panel of dealers and our OEM partner, Hyster-Yale, to relay updated data and resources. We have ongoing conference calls to improve the materials available and it’s about consistent messaging. It’s very important, throughout your organization internally, to make sure you’re consistent and continuing to provide the necessary information.

Related White Papers

Effective Lift Truck Safety as the World Moves Forward

All industries must make adjustments to keep personnel safe and healthy; consistency and collaboration are key, as in order for guidelines to combat the virus to be effective, they must be strictly followed at every opportunity by all involved. Download Now!

Article Topics

Yale News & Resources

Should you lease or buy your lift truck fleet? Electric Trucks are Poised to Tackle the Pressures of E-commerce Improving Distribution Center Metrics New Technology Can Give Lift Truck Operators a Hand 2022 Warehouse Benchmarks Study 70% of forklift accidents in the United States are preventable Robotic lift trucks can cut operating expenses up to 70% More YaleLatest in Warehouse|DC

European Parliament Passes New Law Requiring Supply Chain Accountability Talking Supply Chain: Understanding the FTC’s ban on noncompetes North Carolina Welcomes Amazon’s Newest Mega-Warehouse SAP Unveils New AI-Driven Supply Chain Innovations U.S. Manufacturing is Growing but Employment Not Keeping Pace Maximize Warehouse Space with Mezzanine Automation: Expert Tips Most Companies Unprepared For Supply Chain Emergency More Warehouse|DC