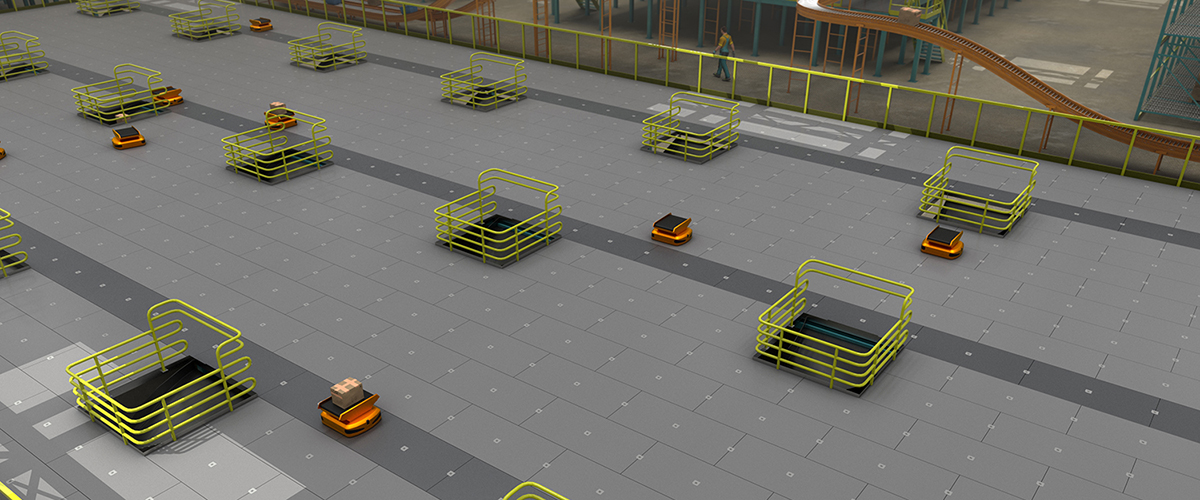

Flooring Is Critical for Successful AMR and AGV Mobile Robot Performance

With ongoing labor retention challenges, higher wages, and the significant increase in e-commerce demand, robotic solutions can deliver higher throughput and greater operational efficiency.

The market for autonomous mobile robots, or AMRs, and automatic guided vehicles, or AGVs, is expected to reach $13.2 billion by 2026, according to Research and Markets.

Fulfillment operations are adding more elevated work platforms and mezzanines to increase capacity. When AGVs and AMRs are to be used on upper levels, the right flooring is critical to ensure they function as intended. Scott McGill, director of sales at Cornerstone Specialty Wood Products (resindek.com), shared several key considerations when specifying automated flooring:

Q: How can a floor impact a robot’s operation?

McGill: To maximize efficiency, AMRs and AGVs must move quickly and consistently to maintain workflow. The surface of the floor must not impede the robot’s movement. If the floor is worn or has uneven surface, it can disrupt the functioning of laser-based navigation.

Concrete tends to crack and spall over time; this can lead to wear and tear on the robot wheels and hardware. If the floor is not level, the robot could roll away from its target point, requiring downtime and manual intervention to get it back to its proper position.

Q: What flooring attributes are most important in a robotic application?

McGill: There are five things to look for:

- Capacity: Has the floor, its steel decking, and elevated structure been engineered to handle both the robots and their loads?

- Coefficient of friction: Has the floor been tested for coefficient of friction and surface roughness? Will the robot operate on the floor as intended?

- Flat, level surface: The swales, dips, and valleys common in concrete flooring can cause a robot to roll away from its intended path.

- Reflectivity: Shiny finishes reflect more light than dull ones. Robots navigating via lasers that aim down to read waypoints on the floor can be confused by a shiny finish.

- Wear resistance: Robotic traffic is highly repetitive, so the floor’s wear resistance is incredibly important to its longevity.

Q: What other flooring alternatives to concrete are there?

McGill: Our ResinDek® floor panels specified with either TriGard® or MetaGard® finishes have been extensively tested with robotics for coefficient of friction, surface roughness, wear resistance, and light reflectivity.

In the last decade, we have provided a variety of ResinDek flooring products to numerous AGV and AMR manufacturers for their testing labs. As a result, millions of square feet of ResinDek panels are in service worldwide with robotic traffic in distribution centers, warehouses, and retail environments.

Q: Any other robotic flooring recommendations?

McGill: Before selecting a floor, involve the robotic supplier to ensure that any testing and evaluation happen early on. The floor should not be considered a commodity, but instead be chosen based on the automation’s requirements. View the entire interview here!

Article Topics

Latest in Supply Chain

The Rise of the Stanley Cup: A Supply Chain Challenge U.S. Blocks Imports from 26 Chinese Cotton Firms Over Forced Labor DP World Expands Freight Network with New Texas Offices GXO Logistics Deploys 500 Robots for Top Sporting Goods Retailer Talking Supply Chain: Why a Stanley cup can disrupt the supply chain UPS Cuts Email Response Time in Half with AI Automation 2024 Salary Survey: Supply Chain Professionals Now Earn Over $100K More Supply Chain