Don’t Just Map Out Your Supply Chain Geographically but Geopolitically Too!

Geopolitical analyst Jacob Shapiro argues that the over-reliance on China as a primary supplier will drive significant changes across global supply chains including how to secure future political risk.

Overreliance on China

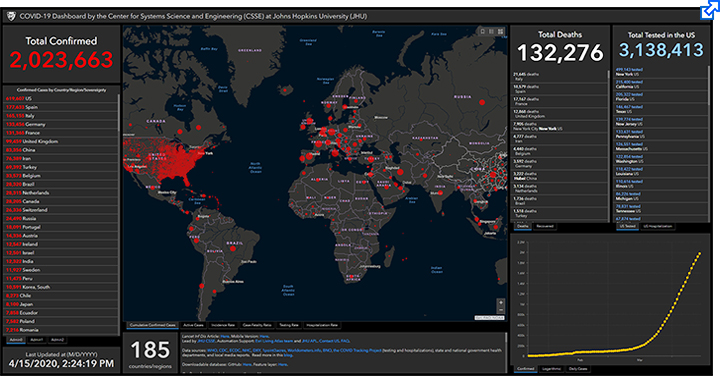

According to Jacob L. Shapiro, a geopolitical analyst, 90 percent of the businesses with a direct impact on their supply chains as a result of COVID-19 are based in the United States of America.

At the same time, China enjoys a dominant position, and in some sectors a monopoly, on supply in those global supply chains.

“While the first rule of supply chain resilience is to avoid single sourcing,” says Shapiro, who advises business clients on geopolitical and political risk, “U.S. and European companies have long been attracted by the cheap skilled labor China has to offer.”

“Regardless of the ultimate impact or duration of the pandemic, the rapid suppression of global economic activity has shown that overreliance on China as a primary supplier has become an intolerable single point of failure.”

I spoke to Shapiro back on March 31, which seems like a lifetime ago in the course of the pandemic. On that day, there were 185,000 confirmed cases in the U.S. and 3,800 confirmed deaths from the virus.

As I write this column two weeks later, there are about 588,300 confirmed cases and 24,480 confirmed deaths. On the 31st, those numbers were staggering; today, April 15th, they are unfathomable.

Decoupling of Supply Chains

While this is what we refer to as a Black Swan event, Shapiro was not so much focused on the here and now during our conversation, but on what comes next, which he predicts will be a decoupling of supply chains and not just a decoupling from China.

Moreover, from the perspective of supply chains, he sees COVID-19 as a catalyst, one of those agents you add to a mix to speed up a chemical reaction that was going to take place anyway. “In 2008, a financial bubble popped,” he said.

“I think the bubble to pop now is China.”

According to Shapiro, the relationship between the U.S. and China began to change in 2012, when Xi Jinping became president of the People’s Republic of China.

In the ensuing years, the Obama administration imposed tariffs on some Chinese-made products, such as tires, but “in 2014 and 2015, it was a chicken war with the Chinese,” Shapiro said during our call.

Meanwhile, companies began to at least explore other options, even if they didn’t fully embrace them, because of rising wages and China’s shrinking cost advantage.

“We continued to use them because China remained super-efficient,” Shapiro noted. “Things began to change in 2016 when the United States declared China a strategic rival. Once China saw that on paper, they reacted.” And, of course, a tariff war followed.

So What Comes Next?

Shapiro acknowledges that some, including some friends in the business community, maintain that “China is the next China.” He thinks that’s the wrong question to ask.

“To me, that question is thinking about a world that doesn’t exist anymore. It’s a completely new ball game. Changes were already underway, and COVID-19 could be the final nail in the coffin.”

Instead, think of supply chains that will be a lot more localized and regionalized. “What supply chain managers need to think about is not a comparative advantage but political risk,” he contended.

“It’s not cheap, but efficient and reliable. They should ask how they diversify so they don’t have all of their eggs in one basket. They should also think about how to secure their supply chains from political risk.”

While there has been a lot of talk about bringing production back to America, Shapiro thinks that it may be true for critical products, like satellites and vaccines, but probably not for the everyday things we’re used to buying on the cheap.

“It’s not going to be about re-shoring to the U.S.,” Shapiro said. “It’s going to be strategically defensible, or reliable, networks.”

If you’re operating in the U.S., you may be looking to Mexico and South America. If you’re operating in China, you may be looking in Central Asia. There are budding alliances forming between Japan, Australia and India that may be able to reduce the economic dependence on China.

Final Supply Chain Advice

Shapiro’s final advice to supply chain executives: Despite the current challenge of getting supply chains back up and running, focus on the long term.

“Don’t just map out your supply chain geographically but politically,” he said. “Ask how could a political squabble, like a trade war or a pandemic, mess up a company’s supply?”

Related Article: Lessons on Mitigating Risk When Unforeseen Events Disrupt the Supply Chain

Related Resources

Companies with Global Logistics Face Unpredictable Challenges

This white paper describes how automation technology helps companies manage market-specific issues by delivering full visibility into all facets - and every location - of their shipping and logistics operations. Download Now!

The Elemica SEE | Visibility Solution Platform

Unleash the power of a digital supply chain with visibility and exception management for optimizing and transforming your order-to-cash and procure-to-pay supply chain processes. Download Now!

The Elemica MOVE | Logistics Management Solutions

Connect to and collaborate with all of your logistics service providers for logistics execution, visibility, site logistics, and freight cost management, and digitize shipment responses quickly and cost-efficiently from your transportation providers for shipment booking and milestone visibility. Download Now!

More Elemica Resources

Article Topics

Elemica News & Resources

The Pharmaceutical Supply Chain Reform We’re Not Talking Enough About – Logistics & Transportation Application Programming Interface Management Ensures Flexibility and Frees Resources Is Your Supply Chain Control Tower an Asset or a Liability? Elemica Announces David Muse as Chief Executive Officer The Current State of Digital Supply Chain Transformation Building a Stronger, More Agile and Resilient Supply Chain through Application Integration Don’t Just Map Out Your Supply Chain Geographically but Geopolitically Too! More ElemicaLatest in Supply Chain

Dollar Tree’s Oklahoma Distribution Center Decimated by Tornado The Era of Self-Driving Tractor-Trailers Set to Begin Is the Trailers as a Service (TaaS) Model Right For Your Business? Why Grocery Shoppers are Leaving Stores to Buy Their Food Online Is There a Next Generation of Truckers? Data Reveals Grim Outlook A Look at Baltimore’s Key Bridge Collapse—One Month Later European Parliament Passes Law on Supply Chain Accountability More Supply ChainAbout the Author