Dock Doors: Critical Valves in the Supply Chain

Many shippers and receivers are lax about their dock operations, but it's the carriers and drivers who pay.

Tales from the Trail: The Rough Road Through the Dock Doors

Last week a friend who’s the manager of a large store in a national retail chain and I went for an evening trail run.

I was looking forward to it as I had just read DAT’s survey of truckers and their complaints, and wanted to get his perspective as a store manager.

He’s the manager of top performing store in a $60B company, so I figured I’d get some insight.

I wasn’t disappointed, but it wasn’t quite what I expected.

Delays and Missed Opportunities are a Major Problem

According to a recent DAT survey of the carriers surveyed, 54% of them said that they wait between 3 to 5 hours every time they’re at a shipper’s dock. Another 9% said that they wait more than 5 hours on average.

From the survey results and the responses to it, it is clear that dock delays are a major problem for carriers, everyone knows about it, yet little is done to remedy the situation.

Most of the carriers said they are seldom paid for the detentions, and when they are, it does not cover their costs, particularly if they miss other load opportunities due to the delay.

“Many shippers and receivers are lax about their dock operations, but it’s the carriers and drivers who are forced to pay for that inefficiency.”

Don Thornton, senior vice president at DAT

Andy, my trail running accomplice, was not surprised at the survey findings, and admitted that drivers were frequently delayed at his store too.

“How do they react, do they get mad?” I asked. “The new drivers do, the regulars stand around and chat.”

“How do you manage the doors?”

“With pen and paper.”

Perhaps I misheard through our panting as we wove our way through the woods.

“Wait a minute, you’re a $60B company… did you say you manage your dock doors with pen and paper?”

“That’s what I said.”

He explained that some appointments are standing appointments; some are scheduled, while others are unscheduled. Even the scheduled appointments are headache. He said it can take a carrier 3-4 calls to reach the scheduler as they’re often away from their desks and sometimes out of the store.

Dock Door Delays and Driver Confusion

On busy days, congestion at the dock doors is common. The store tried to give scheduled loads priority over the unscheduled, but a wait of 2-3 hours is not unusual.

To make matters worse, some dock doors have constraints and cannot accept loads over 15 feet long due to the lack of space inside the store. New drivers don’t know this, so they often dock there then have to back out and re-dock at another door if and when that door is available.

Andy confirmed the survey’s results, dock doors were a major source of delay and loss for drivers. But he was just getting started…

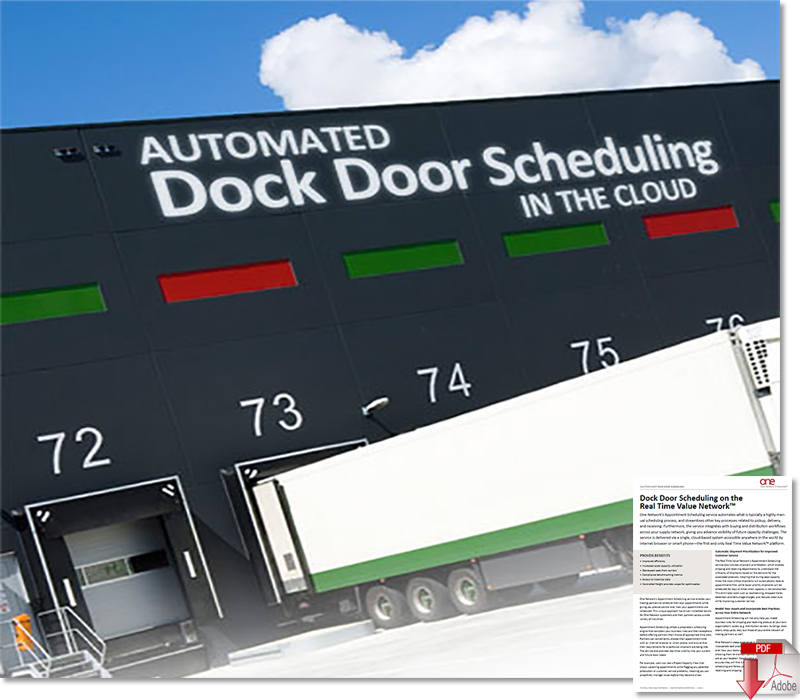

Andy knew the drill, but I told him anyway, “You realize that’s a pretty easy problem to fix? A dock scheduling solution will allow you to time your deliveries, and carriers can do it themselves. They won’t need to call and play phone tag with your guys trying to get an appointment. You can set up various types of doors so the truckers know exactly when and where to dock. Plus, you’ll know what’s in the trucks ahead of time and can prioritize them on based on that if you want to, say if you’re having a promotion and are running low on an item.“

“You don’t know half of it.”

“What do you mean,” I asked.

Beyond the Dock Doors

He went on to explain the ripple effect the dock door chaos had on his job and his store.

- No Process, No Information. “I have a guy that has to manage the doors, be available to take and return calls. And if he calls in sick, it can really throw us off and be a major problem. A lot of the info and the process are in his head.”

- The Doors Tie Up His Resources Unnecessarily. “Since we don’t know what’s coming and when, I often have at least four people tied up at the doors, expecting deliveries that are often delayed for whatever reason. We usually have no idea where the truck is or how late it’s running. I need those people; they could be helping out on the shop floor, restocking and cleaning.”

- Lack of Data, Lack of Insight. “Worst of all, I have no historical data. I can’t look back and review the volume of traffic and resources we’ve used in the past. This makes it really difficult to plan resources and prepare for busy seasons, holidays, and weather-related events. We have to go by memory and guesstimates, but those are pretty imprecise. For example, we know we get roughly double the daily deliveries February through May, so that’s what I plan for but we’re still off quite a bit.”

Yikes. Andy’s team has a lot of experience between them, so they do better than most “flying blind.” I couldn’t help think his day to day job resembled us crashing through the woods at night on a slippery, rocky trail, not knowing what was around the next bend.

Penny Wise, Pound Foolish

Given the critical role dock doors play in the supply chain, that they regulate the flow of goods through the supply chain, it’s astonishing that companies pay so little attention to them.

Dock doors are like valves in your supply chain, they can clog and be the source of major inefficiency.

Andy admitted that their process was very inefficient and unreliable, not to mention frustrating for all involved, for the truckers, for his staff, for him as a manager, and ultimately to his customers.

The good news is that a good dock scheduling solution is probably one of the easiest and most cost-effective ways to gain shipment visibility, automatically prioritize shipments, and to ease bottlenecks and streamline the supply chain.

It’s less exciting than stumbling through the dark and stepping on the occasional snake, but your customers and colleagues will thank you.

Article Topics

One Network Enterprises News & Resources

Blue Yonder announces an agreement to acquire One Network Enterprises for $839 million Blue Yonder Acquires One Network Enterprises for $839M Companies Need to Develop New Innovative Approaches to Supply Chain Design How to Improve Cost of Goods Sold Horizontally Across the Supply Chain How the Global Pandemic Accelerated Supply Chain Visibility, Digitalization, and Automation AI and Data, the Future of Supply Chain Management AI and Supply Chain Problem Solving More One Network EnterprisesLatest in Supply Chain

Trucking Industry Pushes Back on Government’s Electric Mandates Senators Take Aim at Amazon with Warehouse Worker Protection Act Maersk Sees Silver Lining in Red Sea Shipping Challenges Happy Returns Partners With Shein and Forever 21 to Simplify Returns Baltimore Opens 45-Foot Deep Channel Following Bridge Collapse El Paso Border Delays Cost Juarez $32 Million Per Day in Economic Losses Ranking the World’s 10 Biggest Supply Chains More Supply Chain