Cobots Help Balance Reshoring and Worker Challenges

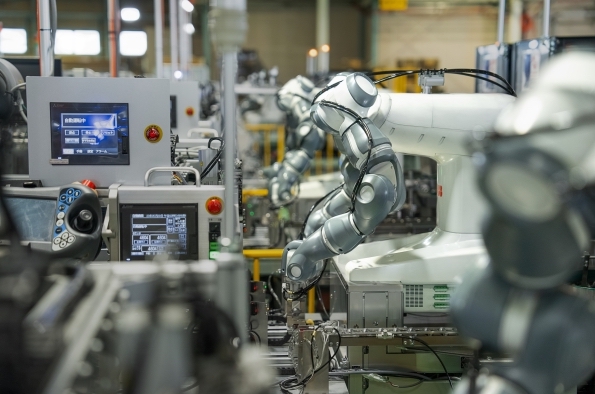

The dual-armed cobots are helping aluminum component supplier reduce assembly time, increase productivity, and increase flexibility.

Reshoring is the goal of many manufacturers, but worker shortages have slowed the process of ramping up production in plants on home turf.

SUS Corporation, a major supplier of aluminum frames and die-cast aluminum components for the automotive and other manufacturing industries, is one of those companies. In the wake of significant disruption to global supply chains in recent years, SUS chose to return to domestic production in Shizuoka, Japan, to better manage its lead times and introduce greater flexibility.

However, the manual and repetitive nature of the production process, coupled with mounting labor shortages, has made it difficult for the company to recruit and retain sufficient workers to achieve the required production volumes. SUS is now turning to ABB’s YuMi cobots to enable the reshoring of production while addressing workforce shortage challenges.

“Reshoring is increasingly viewed as a way to address the challenges of disruptive supply chains and uncertainty, but it can introduce complexities of its own,” said Joerg Reger, managing director of ABB Robotics Automotive Business Line. “Our range of flexible automation solutions can help resolve these, and we’re delighted to see that SUS is benefiting from significant time-savings, enhanced production efficiency, and the ability to quickly adapt to changing supply scenarios. This demonstrates how automation is no longer the preserve of large OEMs alone.”

The solution – a series of YuMi dual-armed collaborative robots – has reduced the assembly time, increased productivity by 20 percent, and introduced much-needed flexibility in response to fluctuations in demand. The company expects to achieve payback on its investment within two years.

The automated solution was developed using ABB’s RobotStudio® simulation software to design and optimize the operation in a virtual space, ahead of deployment in the real world. The simulation verified that YuMi’s seven-axes of movement per arm were able to replicate the complex twisting actions needed during the assembly process. RobotStudio’s accurate calculations for achievable production volumes also made it easy for SUS to make informed decisions about its investment. The company is now investigating adding further cells for other products and automating other processes.

“The robots have taken on monotonous, repetitive jobs, enabling workers to be reassigned to more rewarding tasks such as operation management,” said Akihiro Taki, team manager, Die-casting Team, at SUS’s Shizuoka site. “The new system has also made it possible to operate at night with fewer workers, with the number of dedicated assembly machines in operation reduced from 11 to five.”

SUS is by no means the only manufacturer grappling with these challenges. ABB’s recent Automotive Manufacturing Outlook Survey discovered that nearly a third (31%) of all respondents listed labor shortages among their top three challenges, while 35% ranked labor as their most concerning area when it came to rising costs.

Watch this video to see YuMi in action.

Article Topics

ABB Robotics News & Resources

ABB acquires AI-based autonomous navigation technology provider Sevensense ABB to invest $280 million in its European robotics hub in Sweden ABB Robotics opens U.S. Packaging and Logistics headquarters ABB to expand its robotics factory in Michigan ABB rebrands autonomous mobile robot portfolio ABB survey finds risk from global “education gap” in automation ABB joins Berkshire Grey’s Technology Alliance Program to deliver AI-enabled robotic solutions More ABB RoboticsLatest in Supply Chain

A Look at Baltimore’s Key Bridge Collapse—One Month Later European Parliament Passes New Law Requiring Supply Chain Accountability Baltimore Continues Bridge Recovery With Opening of New Channel How Shippers Can Prep for Hurricane Season Apple Accused of Multiple Human Rights Violations South Korea Finally Overtakes China in Goods Exported to U.S. Talking Supply Chain: Understanding the FTC’s ban on noncompetes More Supply Chain