5 ways to reduce hidden maintenance, repair and operations (MRO) costs

Looking at consumption, order policies and purchase orders can make an impact on your operations costs and MRO budget.

Some things, like death and taxes, never change.

But your maintenance, repair and operations (MRO) budget should not be one of those unchanging items. Many managers think of MRO as a bucket of inflexible costs, but digging into that bucket can reveal significant potential cost savings.

When I review MRO processes at industrial facilities, it’s not uncommon for me to find savings that total as much as 10%, and sometimes more, of the MRO budget. Based on my experience, here are the top five hidden MRO costs typically found and how you can reduce them.

- Unnecessary consumption. Managers often view the consumption of indirect items, such as supplies and tooling, as a fixed cost year to year during the budgeting process. But, there often are opportunities to reduce consumption by making consumption more visible, introducing controls and reducing unnecessary inventories. When fewer MRO items are used, less is spent.

The bottom line: Don’t assume your MRO consumption is fixed. - High purchase order costs. It’s easy to forget that issuing a purchase order isn’t free. Your PO process has costs involved, dominated by associate labor. Studies have found that the cost of issuing a PO often is higher than the value of the items ordered. These PO costs may show up elsewhere on your P&L, but they still can provide a savings opportunity.

How can you chip away at these costs? The biggest savings are usually found in automating some or all of the PO process. A fully manual process, for example, can cost hundreds of dollars per PO. Shifting to an electronic process might cut costs in half, and fully automating it could cut it in half again, or generate even more savings.

The bottom line: It costs money to spend money, so make your PO process as efficient as possible. - Inefficient order policies. Though you won’t find it listed in your expenses, inappropriate order policies also can drive up your MRO costs. One situation I often see is a supply crib filled with an item from an unreliable supplier. The order policy may maintain a relatively high level of inventory for these parts, even if they aren’t used often, require high minimum orders, or be set to reorder at relatively high inventory levels.

Imagine a crib with a maximum inventory level of five and a reorder trigger set to four. That means the facility is reordering every time one of these parts is issued, even though they may be used infrequently. This results in increased transaction costs—in purchase orders (see No. 2), shipping and the like.

The bottom line: Audit your order policies to optimize costs for whatever level of supply you truly need. - Too many suppliers. Taking MRO spend that is split among multiple suppliers and consolidating it with a single distributor can sometimes save money. When going through this process, you may find that consolidation savings can involve more than prices.

Going with a one distributor can cut your MRO supplies cost and reduce transactional overhead. Volume discounts may be the least important savings as transactions can become simpler, shipments can be combined to reduce shipping costs, and some distributors can even provide supply chain solutions to further reduce MRO consumption and costs.

The bottom line: Consolidating with a single distributor that provides additional services can boost productivity and reduce costs. - A narrow mindset on cost control. Finally, many companies end up with higher-than-necessary MRO costs because they approach the budget with a product pricing mindset rather than total cost of ownership. Improving your supply chain processes, increasing the efficiency of your processes and aligning yourself with the distributor and suppliers that provide the highest value can result in significant cost savings.

The bottom line: Focusing solely on price rather than total cost of ownership means you’ll miss on the greater additional cost savings.

Darr Greenhalgh is senior manager of customer solutions at MSC Industrial Supply Co., a leading North American distributor of metalworking and MRO products and services. He has more than 35 years of experience in procurement, project management, lean supply chain management and manufacturing in a range of industries.

Darr Greenhalgh is senior manager of customer solutions at MSC Industrial Supply Co., a leading North American distributor of metalworking and MRO products and services. He has more than 35 years of experience in procurement, project management, lean supply chain management and manufacturing in a range of industries.

MRO Products and Accessories

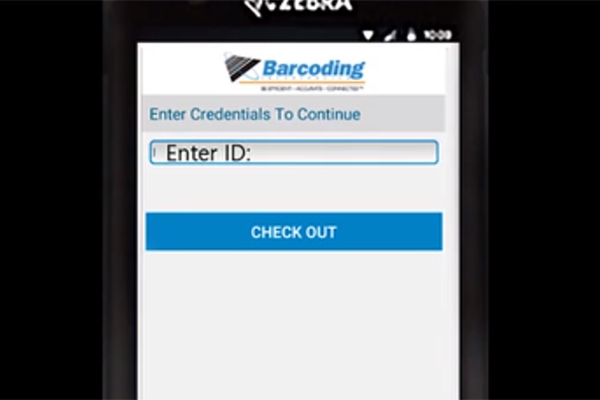

Get Smart mobile application

Get Smart mobile application

New mobile app captures and reports user and device usage data.

HIoTMeter Wireless Equipment Hour Meter

HIoTMeter Wireless Equipment Hour Meter

IoT wireless equipment hour meter helps manage maintenance schedules.

Leatherman Free collection of multi-tools

Leatherman Free collection of multi-tools

Magnetic multi-tool is reliable and easy to open.

Sentinel 1 onboard monitoring system

Sentinel 1 onboard monitoring system

Onboard monitoring system for better control functions.

Food Machinery Grease EP

Food Machinery Grease EP

Food machinery grease has pressure chemistry built-in.

Service program for robotic equipment

Service program for robotic equipment

Extend equipment life with training, parts programs and refurbishment.