Challenges in Your Supply Chain & a Directional Approach to Integrated Business Planning

This first part of this two-part paper evaluates how one should take advantage of the new capabilities SAP brings to the planning arena and also elaborates on how one can mitigate any risk inherent during this transition process, the second part of the paper evaluates the complexity of options faced by customers who may be interested in IBP.

Today's new supply chain strategy is built around the customer and speed of delivery.

The presumption is that if demand sensing is sped up, then supply chain planning and execution will become more aligned with short-term changes in the market.

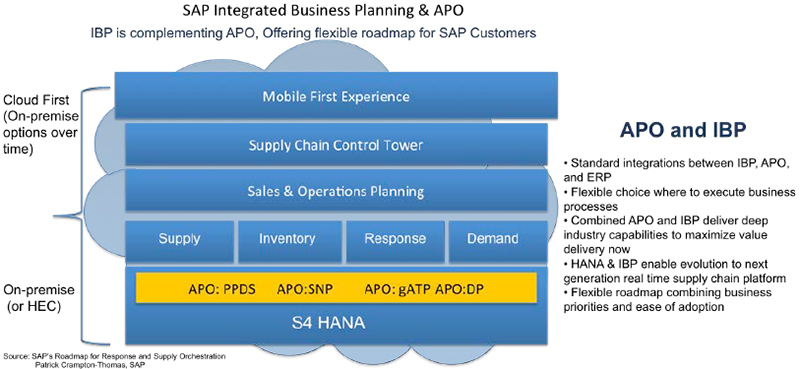

As SAP’s Integrated Business Planning (IBP) platform rolls out, APO will remain accessible during the transition period till 2020 and may continue beyond that with an extended maintenance.

New functionalities of IBP will be made available and can be adopted by organizations as these components are deployed in incremental phases.

This first half of this paper evaluates how one should take advantage of the new capabilities SAP brings to the planning arena and also elaborates on how one can mitigate any risk inherent during this transition process.

SAP is stepping up it's offering beyond the traditional static planning denizens that they have occupied over the last 18 years.

One should understand that APO was delivered for a static planning paradigm, and current requirements in business demand additional capabilities which IBP will address; hence this is not a technology swap but an enhancement of core planning capabilities.

The underlying message is that the new capabilities are required as supply chains evolve into demand networks. This transition will enable users to take advantage of modern technology and the new functionalities to support emerging business needs.

Over the last two years, Integrated Business Planning (IBP) has been gaining popularity in the enterprise software market and has further accelerated in SAP shops with many new customers coming on board.

Non-manufacturing enterprises that are not privy to SKU centric planning are discovering IBP as an excellent solution for orchestrating business rhythms.

The SAP IBP platform has evolved to include planning components beyond Sales and Operations Planning (S&OP).

These additional components now include Predictive Demand Management (PDM), Inventory, Response Supply Orchestration (RSO), and Supply Chain Control Tower (SCT).

Components like Response and PDM are accelerating adoption for IBP among SAP customer base in Consumer Products & Technology. Inventory Optimization is now being received in almost every IBP play.

The second part of this white paper evaluates the complexity of options faced by customers who may be interested in IBP and need clarity on a number of questions.

We address most of the common questions that clients have and provide a directional approach.

For further details and insight, our experienced team is on-deck anytime and anywhere to offer strategic guidance.

Download this paper and discover how you should take advantage of the new capabilities SAP and questions about Integrated Business Planning can be best answered.

What’s Related

Favorites