Zara’s Fashion Retail Supply Chain Strategies

Zara has maintained it’s stand as a leader in the apparel industry and what makes it so profitable is it’s unique supply chain strategies.

“One day it’s in and the next day it’s out” – a popular phrase that often resounds when the apparel industry comes to mind.

The fashion industry is known to run on a high degree of uncertainty.

With ever changing trends it is even harder to predict the market and hence forecast the required raw materials and supplies. In the past the apparel industry has been categorized as more of a push model where the retailer outlets push styles and new outfits to the market.

However, the same strategy is doomed for failure as of today, with new entrants and competitors at every corner, brands are being forced to listen to their customer. It’s important to recognize what chimes with the consumer and quickly respond by satisfying this need. Additionally, every geographic location differs in spending patterns, styles, per capita income etc. and all the clothing lines need to accurately evaluate the demand that will exist in every market.

What increases the complexity of the supply chain is the dependence on exports from other developing countries. Almost 30% of all garments produced in the world are exported in developing nations. Hence, there is a large cost involved in transporting materials and finished goods.

Zara has maintained it’s stand as a leader in the apparel industry and what makes it so profitable is it’s unique supply chain strategies. Zara uses the following principles to increase their net income and maintain a standing of being a brand that is both fashion forward and affordable.

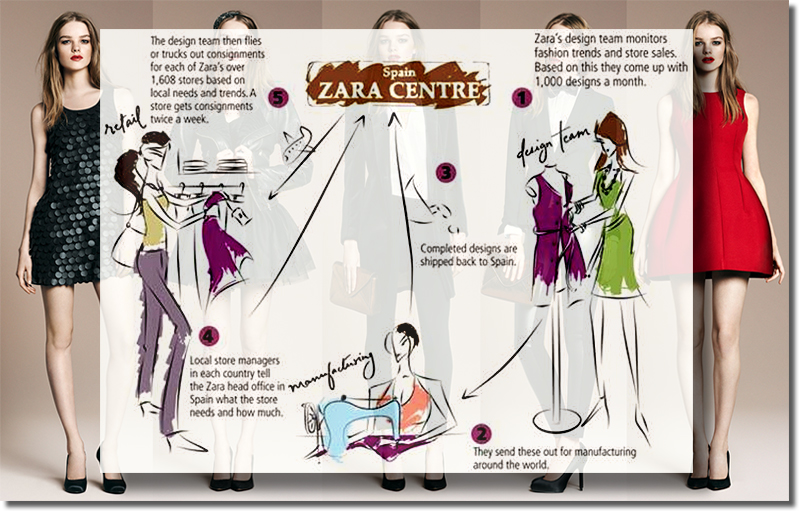

- Quick response to Demand – Zara follows a pull model in their inventory and supply chain management. They create up to 1000 designs every month based on store sales and current trends. They monitor customer spending’s in the store to evaluate and understand what types of designs are being consumed and then accordingly iterate on their next designs.

- Small Batch Productions – Zara has a fast turnover, they produce small number of quantities for every product. This gives them the opportunity to quickly understand what designs are successful. It is also a great way to explore new designs and understand its acceptance rate in the market. This also heavily reduces the risk of producing large quantities of something that the customer does not want. Even though it might seem like a bad idea to invest in different designs, Zara optimizes by using the same material only in different ways.

- Central Distribution Center – Zara has very strong IT systems that back it’s distribution. All the clothes are shipped back to Spain, the central location. From here, it is distributed to different countries and stores is based on individual requirements and needs of the particular locality.

As industries and competitors follow up on Zara’s unique supply chain model, it is. Will Zara not be threatened by the new entrants or old catching up and continue to practice it’s well tested and tried model or they will they be agile and innovate to sustain a competitive edge through supply chain?

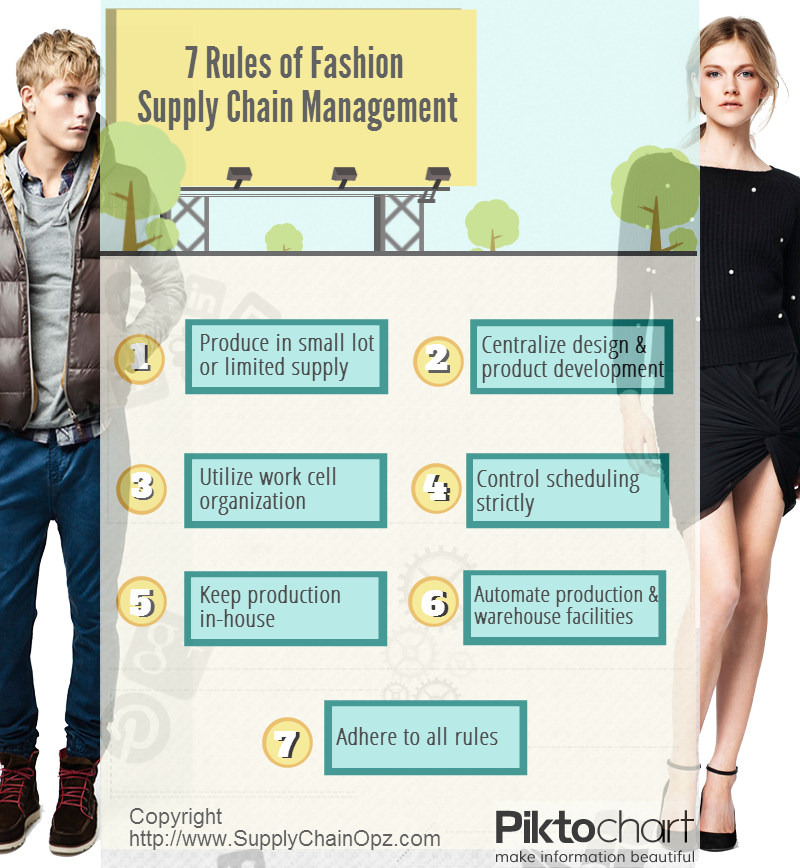

7 Rules of Fashion Supply Chain (Zara Case Study)

Fashion industry is one of the most primitive form of supply chain management and its practices have been extended, adopted and become the best practices that we use today. This article will show you the development of fashion industry and how one company manages to bring the operations into the next level.

Fashion SCM 1.0

In 1984, US Apparel Industry created the task force called “Crafted With Pride in the U.S.A. Council” with the goal to improve the overall competitiveness of the industry. One year later “Kurt Salmon Associates” was assigned to investigate the whole apparel supply chain. The result showed that materials were in the warehouse or in transit as long as 40 weeks! In order to reduce lead-time, Quick Response (QR) strategy was developed and there are 2 core principles, namely, partnership between retailers and suppliers to improve the information sharing and the adoption of technologies such as EDI, UPC Code and point of sales data (POS).

Fashion SCM 2.0

When QR strategy has become saturated, companies have to find the ways to differentiate themselves, some adopt ERP system, others adopt Just-in-Time manufacturing concept. However, there is one company that stands out.

Zara who is the fashion retailer in Spain, has managed to get the attention from academics and the first case study about its strategies was published by Harvard Business School in 2003. In 2004, Kasra Ferdows, Michael A. Lewis, and Jose A.D. Machuca published the article on Harvard Business Review named “Rapid-Fire Fulfillment”. This article was the result of 3-year interviews with the senior management of Zara. We’ve identified 7 rules that we can learn from them as below.

- Produce in small lot: small lot is the unique characteristics of lean manufacturing which is not the case here. The logic behind this is that small lot creates the sense of exclusivity. Customer need to make a quick decision otherwise the next day the products they want will be gone. So customer visits Zara’s stores to see new products more often and this creates the huge amount of traffic and revenue.

- Centralize design and product development: the norm in the apparel (and some other) industries is to develop new products by both in-house staffs and through merchandisers. In the latter case, suppliers need to send samples (through merchandisers) to buyers many many times. Elimination of this back-and-forth communication reduces the time to market drastically.

- Utilize work cell organization: each new product development team has its own designers, sales, procurement and production planners the same way as in a cellular manufacturing. This help Zara to streamline the internal communication a lot.

- Control scheduling strictly: at Zara, store managers can place order 2 times a week, shipments are prepared and delivered within 24 hours (in Europe) and products will be on displayed at stores the same day they arrived. Since everything runs in a stead pace, they can reduce a waiting time at every step of the way.

- Keep production in-house: Zara tries to stay away from low-cost country sourcing and make an investment in the in-house manufacturing as much as possible. The reason is that they believe the in-house production help them to increase the overall flexibility.

- Automate production and warehouse facilities: since Zara believes in time based competition, automation is the key to help them to increase the speed and the accuracy of the operations.

- Adhere to all rules: implementing any one of these rules alone is not quite effective. Then, they have to stick to all rules so the whole supply chain is running like the well-oiled machine.

Source: SupplyChainOpz

Conclusion

Zara’s supply chain is a very good example of the strategic alignment because people, processes and practices support time-based strategy perfectly.

Related: Omni-Channel Expertise in Fashion Retail

Article Topics

Blue Yonder News & Resources

Blue Yonder announces an agreement to acquire One Network Enterprises for $839 million Blue Yonder Acquires One Network Enterprises for $839M Frictionless Podcast: Understanding Your Supply Chain Goals with Ann Marie Jonkman Blue Yonder announces acquisition of flexis AG Supply Chain Management (SCM) applications keep the supply chain humming How Collaborative Efforts Can Enhance Reverse Logistics Netlogistik partners with SVT Robotics to resell SOFTBOT platform More Blue YonderLatest in Supply Chain

U.S. Manufacturing is Growing but Employment Not Keeping Pace The Two Most Important Factors in Last-Mile Delivery Most Companies Unprepared For Supply Chain Emergency Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam More Supply Chain