Working With Goods-to-Person Picking to Deliver Parts to the Assembly Line

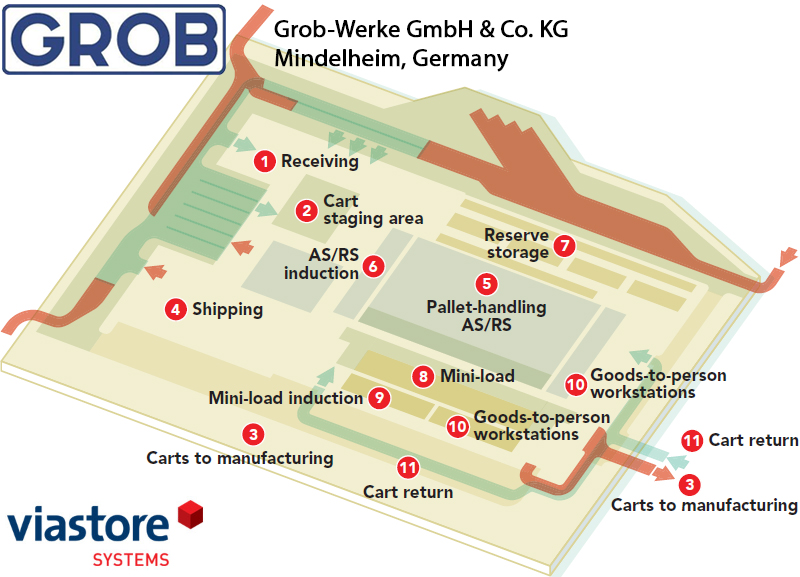

In Grob’s new parts and raw materials warehouse, automated and conventional storage work with goods-to-person picking to deliver parts to the assembly line.

Grob’s new logistics center, the company’s term for its parts and raw materials warehouse, is adjacent to a 1.2-million-square-foot manufacturing facility.

A pallet-handling automated storage and retrieval system (AS/RS), a mini-load AS/RS, conventional storage and goods-to-person picking methodologies provide the fulfillment engine that delivers parts to the assembly line.

Meanwhile, a vision system captures information about the items being picked and the amount of product left on a pallet or in a storage container.

That information is used to improve the quality and accuracy of picks and to drive replenishment.

Receiving and putaway: Trucks are unloaded and processed in the receiving area (1). From there, incoming merchandise follows one of four paths.

1. For immediate use: Product that is required immediately for assembly is placed on a cart in the cart staging area (2) for delivery to one of the assembly lines in the adjacent manufacturing area (3). Similarly, some items may be packaged and staged in the shipping area (4) for delivery to customers in need of spare parts.

2. Pallet-handling AS/RS: Product that is palletized on a Euro pallet receives a license plate bar code label and is delivered to the induction area (6) for the pallet-handling AS/RS (5). The remaining product can be palletized on a Euro pallet that is labeled for induction into the AS/RS (5).

3. Manual reserve storage: Items that are too large, heavy or cumbersome for the automated system are delivered by lift truck to the reserve storage area (7). The driver receives a suggested storage location from the warehouse management system (WMS), but has the option of choosing another storage location. The driver scans the license plate bar code and the storage location to confirm putaway into storage.

4. Mini-load system: Materials destined for the mini-load system (8) are identified in the receiving area (1) and placed in a storage container that then receives a license plate bar code label. The containers travel by conveyor to the mini-load system induction area (9). The container is scanned by the camera-based vision system before it is automatically putaway into a storage location chosen by the WMS.

Regardless of the storage location, the enterprise resource planning (ERP) system tracks the identity of the products on the pallet. The WMS system only tracks the storage location of the pallet.

Picking: The facility manages three picking processes, including manual picking from the reserve storage area (7), the pallet-handling AS/RS (5) and the mini-load system (8). Orders are downloaded from ERP system into the WMS and are then sent to a dispatcher who plans the work. They are released to the floor by a work center that monitors and manages the workflow in the logistics center.

Items that are stored in the reserve storage area (7) are picked to a pallet by a lift truck operator and then delivered to the cart staging area (2). Meanwhile, pallets in the AS/RS (5) and storage containers are delivered to goods-to-picking stations in each area (10).

The system delivers picking instructions to the order selector at one of the goods-to-person workstations (10). A pallet may be used in its entirety or just a few cartons may be removed and placed on a cart. Similarly, individual parts and items are removed from storage containers and placed in a carton on a cart. After picking is complete, the pallet or container is returned to storage in the respective area.

Once the last item for an order has been picked at the goods-to-person stations (10), the order selector is directed to take the cart to the cart staging area (2).

Cart delivery: Orders for carts are released on a just-in-time basis. The carts are delivered to staging areas for each of the assembly areas in the factory (3). A specialist in the assembly area identifies empty carts that can be returned (11) to the logistics center and is responsible for delivering the right cart to the right workstation.

System Suppliers

System design, pallet handling AS/RS, mini-load AS/RS, goods-to-person workstations, WCS & WMS integration: viastore systems

Related: Switching from a ‘Person-to-Goods’ to an Automated ‘Goods-to-Person’ DC Operation

Article Topics

viastore systems News & Resources

Updating Existing Warehouse Equipment and Software Can Mitigate Today’s Fulfillment Challenges Turning Existing Warehouses into Efficient, Optimized Fulfillment Machines Automation as a Cold Chain Labor Strategy Best Practices for a Successful Cold Storage Automation Implementation Automation: An Effective Labor Strategy in Cold Chain Warehousing and Distribution AS/RS Modernization Reduces Downtime and Saves Thousands of Dollars at Food Service Facility Automation Considerations for Frozen Product Storage More viastore systemsLatest in Warehouse|DC

North Carolina Welcomes Amazon’s Newest Mega-Warehouse SAP Unveils New AI-Driven Supply Chain Innovations U.S. Manufacturing is Growing but Employment Not Keeping Pace Maximize Warehouse Space with Mezzanine Automation: Expert Tips Most Companies Unprepared For Supply Chain Emergency Microsoft Unveils New AI Innovations For Warehouses Spotlight Startup: Cart.com is Reimagining Logistics More Warehouse|DCAbout the Author