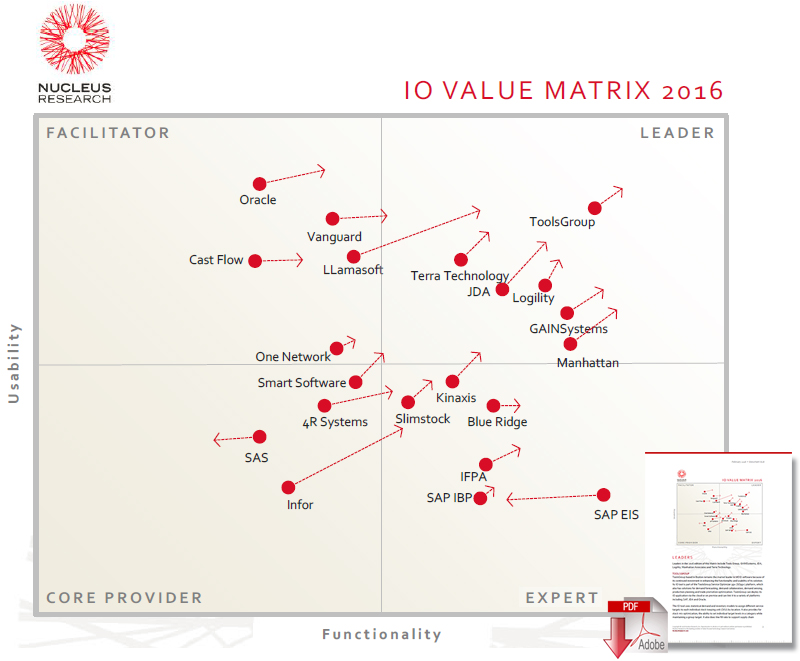

What’s New in Nucleus Research’s 2016 Inventory Optimization Value Matrix?

Principal Analyst James Cooke of Nucleus Research just published his 2016 Inventory Optimization Value Matrix which highlights this year’s key trends, including functionality and usability.

Nucleus Research is known for focusing on the financial impact of technology, so that is where James Cooke, principal analyst, begins.

He reiterates why his firm sees inventory optimization (IO) solutions as so important.

“More than almost any other supply chain application, IO solutions can have a huge impact on a company’s finances.”

Historically, Nucleus Research found that “IO tools provide the highest time to value for companies with complex or global supply chains with large stock holdings and numerous stocking location,” and can reduce inventory by 10-30 percent.

This, he says, creates a large value proposition for leading IO vendors who can “offer a high return on investment [ROI] by providing sophisticated solutions to streamline inventory across the entire supply chain while maintaining the correct amounts of stock to drive sales.”

Cooke says that minimizing inventory “frees up working capital for the business and, by guaranteeing that the company has the right stock on hand, ensures availability of products, parts or materials to provide steady sales for the enterprise.”

Interestingly, he notes that while most companies justify inventory optimization based on inventory savings, improving service to customers is actually the biggest motivation and payback in most projects.

Cooke says that IO strategies tend to differ by industry: retailers focus on what and where to hold inventory across a multi-channel environment; whereas manufacturers emphasize production capacity; electronics firms worry about obsolete inventory.

Inventory optimization vendors, Cooke says, are providing more prescriptive analytics and are working to improve usability. Leading vendors, he says, are reinvesting in functionality, analytics, and data and model visualization capabilities.

Cooke points to specific trends:

- Continued focus on improving multi-echelon inventory optimization (MEIO) functionality to balance stock across multiple sites in a supply chain network.

- Increased use of machine learning to find patterns in seasonal and promotional sales and for new products that lack sales history. Machine learning is especially helpful in calculating inventory for items with high demand variability an seasonality, says Nucleus.

- More scenario analysis that allows planners to balance cost and service trade offs when making decisions. That goes for reviewing past choices, too. Nucleus cited ToolsGroup’s Instant Replay supply chain simulation tool, which lets planners compare prior events, scenarios, and decisions by customer, SKU and location.

- Improved demand signals - As companies aspire to market-driven supply chains, Cooke says they need to sense demand as it occurs. Companies often use point-of-sale data to trigger inventory replenishment. For instance, ToolsGroup’s partnership with Retail Velocity incorporates a demand signal repository into its demand sensing platform to store and harmonize store demand information from multiple sources to get rapid upstream information.

- Usability is increasing crucial, Cooke says, emphasizing data visualization, dashboards and notification alerts, including for mobile devices. Small and medium-size companies don’t have sufficient staff to dedicate users to an IO tool. Planners at large firms are crunched for time and need facts quickly. Dashboards, drill-down capability and report builders provide visualization for analytics and models that they need.

Cooke adds that larger enterprises are starting to consolidate their planning operations into centralized teams of dedicated users.

At small and midsized businesses (SMB), the biggest obstacle he says is supply chain acceptance, hence intensifying the need to make tools easier to use and more intuitive.

Source: ToolsGroup Blog

Article Topics

ToolsGroup News & Resources

Digital Transformation in Supply Chain Planning: 2021 Study shows 74% of digital supply chain planning transformations influenced by Covid Machine Learning Steps Up Retail Performance Machine Learning, Little Black Dress or Accessory? Mastering the Long Tail & Intermittent Demand Intermittent Demand is Not Unforecastable Demand National Health Service Blood Supply Chain Study More ToolsGroupLatest in Supply Chain

UPS Struggles in First Quarter With Steep Earnings Decline How Supply Chains Are Solving Severe Workplace Shortages SAP Unveils New AI-Driven Supply Chain Innovations How Much Extra Will Consumers Pay for Sustainable Packaging? FedEx Announces Plans to Shut Down Four Facilities U.S. Manufacturing is Growing but Employment Not Keeping Pace The Two Most Important Factors in Last-Mile Delivery More Supply Chain