Using SWOT Analysis to Prepare Your 2020 Supply Chain Technology Strategy

Supply chain expert Daniel Stanton explains how to conduct a SWOT analysis to prepare your 2020 strategy and define the challenges your supply chain will face and how you should use technology to drive improvements.

Using SWOT Analysis to Create Your Strategy

In my last article, “The Big Supply Chain Story of 2019: Transparency and Risk” I argued that 2019 was a year of risk and uncertainty for supply chains.

Now it’s time to look forward to 2020 and prepare for the future.

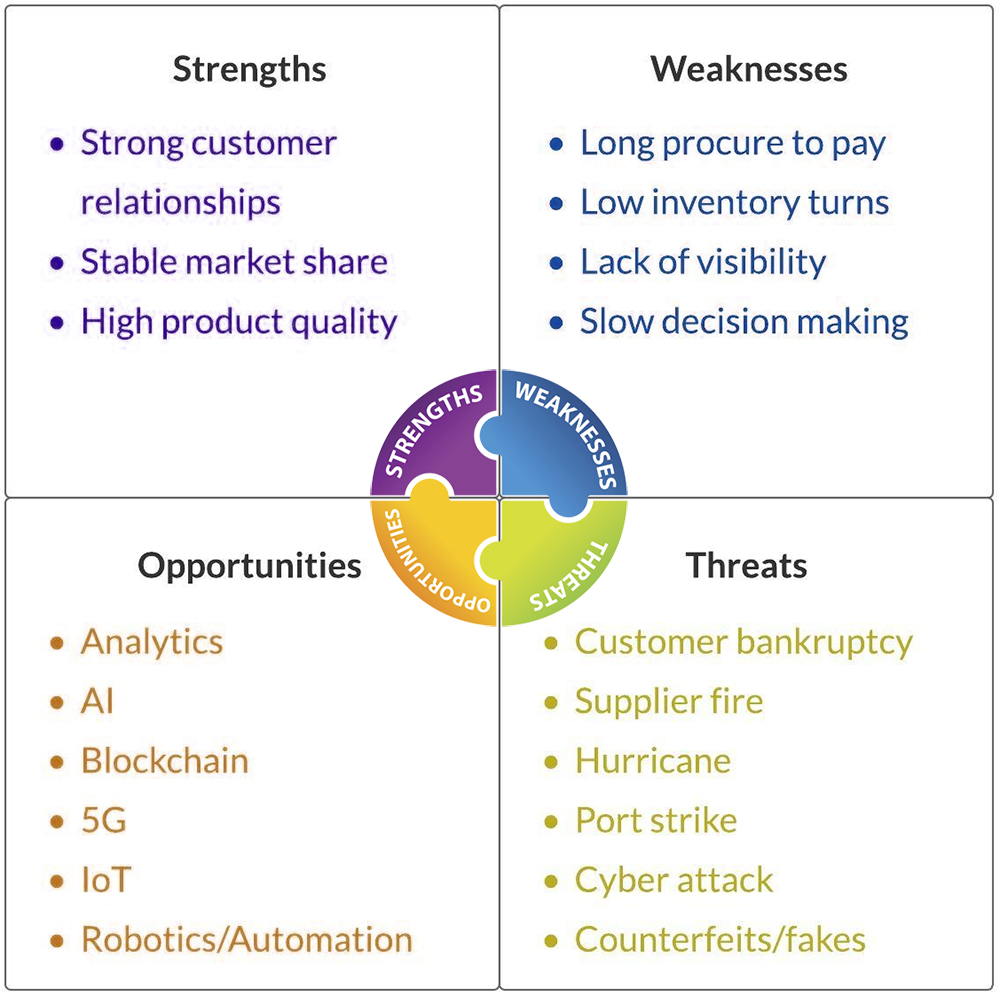

A good place to start developing your supply chain technology strategy is with a tool called a SWOT Analysis.

SWOT stands for Strengths, Weaknesses, Opportunities, and Threats.

Here’s a simple example of a SWOT Analysis for Acme Corporation, a (fictional) mid-sized company that manufactures widgets:

- Strengths: Acme has a solid position in its industry. They’re known for making quality products and have stable, long term relationships with many of their customers.

- Weaknesses: Acme’s supply chain is not very agile. They’ve gotten complaints from suppliers about paying invoices too slowly. They have inventory gathering dust in the warehouse. And they have limited visibility to shipments coming in from suppliers or going out to customers.

- Opportunities: Acme’s leaders know that new technologies could help them make improvements. But they don’t have a good understanding of how they work, how much they cost, or what it would take to implement them.

- Threats: The Acme supply chain is vulnerable to all kinds of risks. Last year, a significant customer went bankrupt, leaving Acme with unusable inventory and unpaid receivables. And one of their suppliers suffered a fire, leading to a shortage of raw materials. There are lots of other risks that could emerge at any moment, and cause major challenges for Acme. From cyber-attacks to the threat of counterfeit products, to the potential for trade wars and port strikes. The list of threats is long!

A good way to organize a SWOT Analysis is with a chart like this one:

You can create a SWOT Analysis on your own, or with input from your team. As you do, you’ll notice that the items on the left of the SWOT Analysis chart are basically “good,” and the items on the right are basically “bad.” You’ll also notice that the items on the top of the chart are “internal” to the company, and the items on the bottom are “external.’

Preparing Value Propositions

The great thing about SWOT Analysis is that it provides the foundation for creating a focused, forward-looking supply chain strategy. And it helps you strengthen the pitch for investment opportunities by creating a solid value proposition for each of them.

Just take a look at the items on the right side of the SWOT chart and then ask, “What could we do to mitigate or eliminate these Weaknesses and Threats?” Your answers to that question should all be added to your SWOT as opportunities.

As you do this, you’ll often discover synergies, because some of the opportunities can help to mitigate several different weaknesses or threats. For example, implementing technology like GPS tracking that improves the in-transit visibility of inbound shipments could simultaneously provide faster response times to disruptions, better metrics for carrier performance, and improvements in inventory management.

“Just take a look at the items on the right side of the SWOT chart and then ask, “What could we do to mitigate or eliminate these Weaknesses and Threats?”

You may also notice that some of your opportunities start to overlap or converge. Going back to our example, GPS technologies might need to be combined with a cloud-based transportation management system, and an artificial intelligence processing engine. That convergence makes it easier to see how technologies need to be bundled in order to provide solutions that will be valuable for your business.

Next, we need to create value propositions. Your value propositions should clearly explain the benefits that you expect from each opportunity. Synergies and convergence help you strengthen the value proposition for each investment opportunity. Then, once you have a clear perspective on the impact an opportunity could have, you can frame the value proposition as a sentence:

“(Opportunity) would solve (problem) for (user) by (benefit).”

Here’s an example: “GPS transmitters would solve the problem of shipment tracking for our logistics analysts by providing real-time location data about every container.” Because of synergies, you might end up with several value propositions for the same solution. In other words, there could be multiple reasons to pursue an opportunity.

Linking each opportunity to your supply chain’s weaknesses and threats makes it easier to explain the basic value proposition. Of course, you can then build on the value proposition by providing quantitative and qualitative data to support it. Acme might discover that they had ten incidents in the past year in which logistics analysts spent 100 hours trying to track down lost shipments. So they could use that cost data to help justify the investment in their GPS trackers.

Pursuing the Best Opportunities

When you’ve defined the value proposition for each opportunity, the next step is to establish your priorities and create a strategy. You might be able to do a simple cost-benefit analysis. For example, sometimes you can calculate a return on investment (ROI) or a net present value (NPV) for each opportunity.

But while we all want to have a clear cut business case before investing in a project, the benefits of some investments are hard to quantify in advance. And this happens a lot with new technologies. That doesn’t mean they’re bad investments – it just means they have more risk.

We can mitigate this investment risk in three ways:

- Professional Development. As supply chain leaders, part of our job is to educate ourselves about the new technologies that are out there, and how other people are using them. Industry publications and conferences are fabulous opportunities to do this kind of reconnaissance. And there are tons of online courses and webinars that are cheap, or even free. The more we know, the easier it is to separate the signal from the noise.

- Strategic Partnering. Instead of focusing purely on cost, we can seek out vendors, integrators, and consultants who take the time to learn our business and help us understand the value that new solutions could provide. Tools like Gartner’s Magic Quadrant can provide a starting point for identifying vendors that we should consider.

- Project Management. Using solid project management processes can make sure that implementations go the way they are supposed to and minimize the opportunity for surprises or failures. While vendors have an important role to play in managing a project, there tend to be a lot fewer surprises when there’s a trained project manager from the client who is actively involved in implementation.

Planning for 2020 and Beyond

To deal with the uncertainty our supply chains are facing, we need to focus on identifying and implementing technologies that help us be more flexible and responsive. Using SWOT Analysis is an easy way to define the best opportunities for investment and craft value propositions to support them. But at the end of the day, successful execution depends on our commitment to professional development, strategic partnering, and effective project management.

About the Author

Daniel Stanton is President and Co-Founder, SecureMarking, also known as “Mr. Supply Chain” and is the author of Supply Chain Management For Dummies and several popular supply chain courses on LinkedIn Learning. He is also a co-founder of SecureMarking, which has developed a robust solution to address the growing threat of counterfeit, black market, and grey-market products in global supply chains.

Related Article: 3 Facts Your Supply Chain Track & Trace Visibility Platform is Not Telling You

Case Study Paper

Solving Supply Chain Problems Outside the TMS

In this case study paper, we detail how Rockwell Automation uses RateLinx’s Data-as-a-Service to improve its freight management operations without a traditional transportation management system. Download Now!

More from RateLinx

Article Topics

RateLinx News & Resources

Optimizing Parcel Spend with Reveel and Ratelinx Improving Your Logistics Carrier Request for Proposal Process Focusing on Transportation Costs Instead of Manually Resolving Freight Exceptions Improving Customer Service Through Freight Spend Visibility 5 Reasons Your Logistics Cost-Savings Initiatives Are Suffering Integrating Data Streams Improves Retail Supply Chains Using SWOT Analysis to Prepare Your 2020 Supply Chain Technology Strategy More RateLinxLatest in Supply Chain

Microsoft Unveils New AI Innovations For Warehouses Let’s Spend Five Minutes Talking About ... Malaysia Baltimore Bridge Collapse: Impact on Freight Navigating TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility More Supply Chain