The Introduction of Supply Chain 4.0, Private Wireless, and 5G

Macro drivers such as the rapid growth in e-commerce and the introduction of Industry 4.0 are fueling a boom in logistics, 4.9 and 5G private wireless networks are helping operators stay competitive and help their customers take just-in-time management to another level.

Five Mega Trends Impacting the Logistics Industry

First, there has been major consolidation over the last decade driven by cost pressures, customer expectation for reduced delivery times, and improved quality of service.

Second, geopolitical tensions and trade disputes in the past few years have caused some global supply chains to consider moving manufacturing and distribution facilities closer to their customers (near-shoring).

The Third is the drive for environmentally sustainable solutions, which also drives a more decentralized supply network and solutions like rail transportation where possible.

Fourth is the new additional strain that Covid 19 has put on the global supply chain. Pre-Covid, some businesses wanted to optimize their supply chain by using warehouses in lower-cost jurisdictions and relying on effective logistics to manage spikes. But the pandemic caused abrupt breakages in the chain, forcing businesses to think again and get more resilient to ever-changing market dynamics.

Fifth is a new competition. Amazon and Alibaba have shown what is possible with supply chain management and operate their own distribution businesses.

Private wireless networks, starting with 4.9G (super-charged 4G) and migrating to 5G as business needs emerge, bring a number of enablers - ultra-low latency, high bandwidth, wide-coverage, and mobility - which, combined with simple deployment of IoT devices provide the perfect platform on which logistics businesses can drive digital transformation.

For instance, cost pressures can be managed by automating processes and using robots. These require low latency which can’t be provided by WiFi but can be delivered on private wireless networks. Digital twins of the supply chain process can give customers the confidence they need in a parcel’s logistics journey.

Enabled by IoT and analytics platforms, logistics operators can provide a step-by-step trace of where a package originated, how long it sat in a warehouse, and how it was handled in transport. As operators continue their digital journey they can upgrade to higher bandwidth 5G to scale warehouse automation and enable augmented reality and 4K drone inspections for improved quality of service.

Governments are recognizing the opportunity that private wireless and 5G brings to the business. Many countries have released spectrum for private wireless industrial site use and Ofcom in the UK, and Bundesnetzagentur in Germany is now providing license spectrum suitable for 5G private wireless.

Industrial Digitalization and Automation

As the world ships more goods, logistics operators are grappling to reduce delivery time, waste, and costs. At the same time, they are seeking to give customers transparency in the supply chain, they are having to adapt to changing levels of demand and supply, and they need to be able to offer customized solutions and higher quality service.

These goals will be achieved using digitization and automation in what the industry is calling Supply Chain 4.0. And it’s being made possible by new telecom networks and the Internet of Things (IoT) where sensors can be connected to almost anything. In this new world order, all goods are connected, machines are controlled remotely or autonomously, and big data analytics creates self-optimizing networks fueled by artificial intelligence.

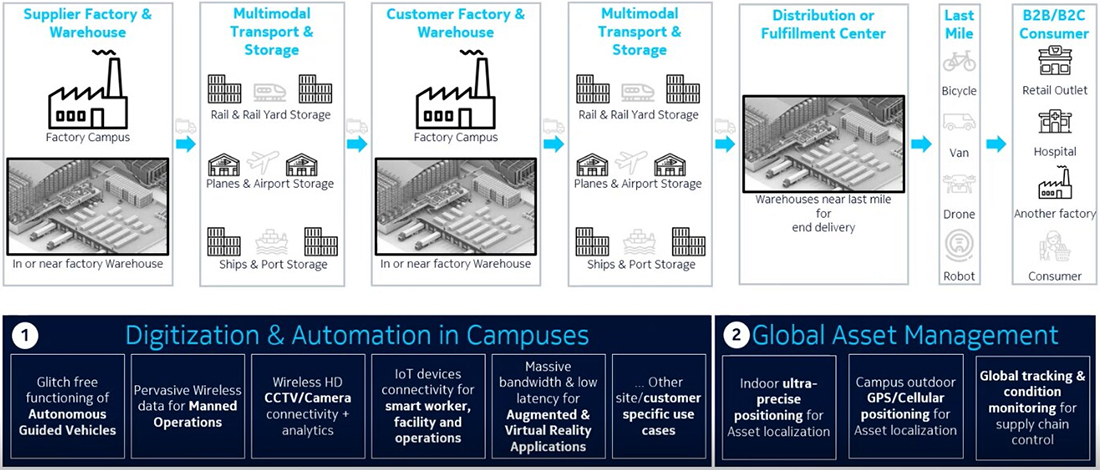

In a typical supply chain, materials travel from the supplier to the customer factory where they are assembled into goods and then sent to a distribution center. 4.9G and 5G private wireless networks and IoT have a role in digitizing and automating the factory, warehousing, and transportation environments. Processes that were done manually such as packing, moving, and controlling inventory can now be completely automated. Augmented and Virtual Reality can remove the operator from the immediate vicinity.

5G and IoT also support the last mile delivery whether that be to the retailer, another factory, or directly to the end consumer. Goods can travel by sea, plane, rail, road, and increasingly by drones; Asset management services such as indoor ultra-precise positioning, global tracking, and condition monitoring provide operators with asset localization and supply chain control.

Wi-Fi vs Private Wireless

Factories, warehouses, and ports share similar challenges. All require dynamic changes to the physical layout which would be impractical if fixed cables were used for connectivity. Likewise, the heavily metallic environments create Wi-Fi blind spots since signals can’t penetrate through the shelves, production line equipment, or containers. And all environments rely on automation which requires low latency and reliability in the network which Wi-Fi can’t provide.

Private wireless offers greater capacity, a more robust signal, lower latency, greater security and can be used when connected devices are on the move.

Transitioning to a private wireless network also simplifies the technology for logistics operators by replacing all the existing networks such as Wi-Fi for data, voice solutions over the public network, an IoT network such as LORA, and separate ultra-wideband networks for indoor positioning.

And Private Wireless can start today with 4.9G for reliable connectivity for critical use cases and be migrated to 5G as needs are expanded.

Moreover, private wireless enables network slicing whereby a dedicated slice of the network can be allocated for particular services, or in the case of a logistics park, the park owner can provide private wireless for the whole park and offer individual businesses their own dedicated slice of the private wireless network.

Private Wireless Network Advantage Over Wi-Fi

- Higher reliability with fewer blind spots and better signal penetration

- WiFi works better when devices are stationary. Wireless networks are also designed to connect devices that are on the move

- Greater capacity. A private wireless network can handle several thousand devices per cell, whereas Wi-Fi can only handle up to 15 devices per access point

- Most importantly, lower latency, even with 4.9G, for more sophisticated use cases such as robotics which work to Service Level Agreements (SLAs)

- Operators can start with a 4.9G network and upgrade to 5G with a software patch to add capacity and lower latency as required

Download the White Paper: Networking Solutions for the New Age of Industry

The early adoption of a private wireless network at Nokia’s Oulu facility enabled the company to maintain productivity and delivery for its customers during the pandemic. Robots can add telepresence and material transport to the production line, multiple sensors utilize the network for communication and video analysis assists quality assurance without having people physically present on-site (watch the video above).

The 5G Difference

While 4.9G private wireless networks can support many of today’s use cases for logistics operators, as their digital needs develop, operators can easily upgrade to 5G.

As warehouses and factories are automated, operators can reduce costs by migrating to edge computing; which requires the ultra-low latency and ultra-high reliability of 5G. Here the bulk of the computing power of the robots is moved to the network core, meaning robots can be lighter, more agile, use less energy, and are less expensive. 5G also enables the deployment of Virtual and Augmented Reality, 4K camera-based applications which can be used for ultra-precise monitoring and in-built indoor geo-positioning capabilities to help track assets.

Simplification is crucial when security is considered. With more connected devices, the rate of attempted attacks is increasing. According to the Nokia Threat Intelligence Report published in October 2020, there has been a 100% increase in IoT malware infections since 2018, and IoT devices now make up roughly 33 percent of infected devices, up from about 16 percent in 2019. By adopting network slicing over 5G, operators can create virtual private networks for insecure devices thereby securing them by default.

5G also provides a sustainability advantage. 5G is more energy-efficient and can potentially provide 100 times more traffic with the same energy.

Asset Management

A whole ecosystem exists for sensors that can be attached to packages and machines which can be tracked and monitored through services such as Nokia’s Worldwide IoT Network Grid (WING). At the basic end, sensors enable operators to track location and motion and can also provide geofencing whereby a response is triggered when the device enters or leaves a particular area. In the automotive world, carmakers (OEMs) subcontract the manufacture of many parts, but the OEM retains ownership of the tools, for example, the die used to press a door. Using IoT geolocation they can monitor the tools, which is essential for tax and production oversight. At the top end, operators can monitor the condition of packages through temperature and vibration checks.

Nokia’s Role in Private Wireless

Nokia has more than 220 private wireless enterprise customers worldwide, of which 30 comprise 5G. In July 2020 the company announced the first commercial 5G standalone (SA) private wireless networking solutions for enterprise customers, paving the way to accelerate digitalization in the most demanding of use cases, where cloud, robotics, and autonomous machine operations create mission-critical demands for reliable low latency and high data rate.

For a typical logistics operation of 5,000 m2 plus, the equipment to operate the network would fit in a suitcase including the radio antenna for inside and outside and with ranges of a few meters to 50km. Nokia’s Digital Automation Cloud (Nokia DAC) plug-and-play solution is an industrial-grade digital automation service platform that provides a reliable, secure, and high-performance private wireless network. A compact system with automation enablers, it comprises network equipment and a cloud-based operation monitoring system. With Nokia DAC, users can securely collect, process, and host all generated proprietary data on-site. For more complex operations, logistics operators can customize their network according to needs with Nokia Modular Private Wireless. Both solutions are available in 5G.

Alibaba’s Cainiao

Nokia has deployed a private wireless network at Alibaba’s Cainiao smart logistics network warehouse in China to control multiple automated guided vehicles (AGVs) operating at the facility. Communication control with the AGVs improved dramatically with reduced latency in the network to below 50Ms.

Read the Article and View the Alibaba Cainiao Video: An Intelligent Supply Chain for a Digitally Connected World

Related Resources

Building an intelligent Supply Chain of the future

This eBook shows you how Nokia networking and communication solutions enable a digitized and automated end-to-end supply chain that can help your organization eliminate supply chain resource waste and accelerate cycle times to transform efficiency and cost. Download Now!

Go Allwhere: The Architecture of Industry’s Digital Age

In this original storybook, Go Allwhere interactively captures the hyper-connected new possibilities of Nokia’s industry segments, including manufacturing, transportation, and the public sector Download Now!

Networking Solutions for the New Age of Industry

This white paper describes how the “Automation of Everything” era will be brought about by digital interfaces, data analysis, and control of the physical world through networks employing the Nokia Bell Labs Future X for industry architecture. Download Now!

More Resources from Nokia

Article Topics

Nokia News & Resources

Wireless mobility moves the bar higher Warehouse automation accelerated with private wireless networks An Intelligent Supply Chain for a Digitally Connected World Building an intelligent Supply Chain of the future Go Allwhere: The Architecture of Industry’s Digital Age The Introduction of Supply Chain 4.0, Private Wireless, and 5G Networking Solutions for the New Age of Industry More NokiaLatest in Technology

Spotlight Startup: Cart.com Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Apple Overtaken as World’s Largest Phone Seller Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Talking Supply Chain: Procurement and the AI revolution More Technology