The Growing Risk of Transporting Crude Oil by Rail

Following the recent CSX incident, someone asked me “Why do we transport something so dangerous via rail?” That’s a good question. Why do we do it?

By now you have probably heard that a CSX train carrying Bakken crude from North Dakota’s shale oil fields derailed and caught fire.

The oil was bound for a coastal oil shipping depot owned by the midstream Master Limited Partnership Plains All American Pipelines in Yorktown, Virginia.

While the cause is still under investigation, the train was carrying 109 tankers of crude oil. 26 of the cars left the tracks, and several caught fire. Some reportedly ended up in a tributary of the Kanawha River.

Fortunately, there were no casualties from the accident, but one thing is certain: There will be more incidents like this, and it’s a matter of time before another incident like this happens in a more populated area. While there are safeguards in place to minimize the risks when these trains have to go through towns, the disaster in Lac-Mégantic, Quebec that claimed 47 lives emphasizes the risks of transporting flammable liquids.

Following the incident, someone asked me “Why do we transport something so dangerous via rail?” That’s a good question. Why do we do it?

It’s really very simple. Most of the country’s transportation system is based on oil. The production and sale of oil in the U.S. is a legal activity, and oil producers look to get the highest possible price for their product. Given that much of the nation’s refining infrastructure and demand is in coastal locations, and most of our oil production is not, in order for supplies in mid-continent regions like the Bakken Formation in North Dakota to reach the demand centers it must be transported.

An oil producer in North Dakota who could only sell oil locally for $40 per barrel (bbl) might obtain $60/bbl on the East Coast. Thus, as long as the local price plus the cost of transport is less than the price at the destination, the producer is going to want to ship the oil.

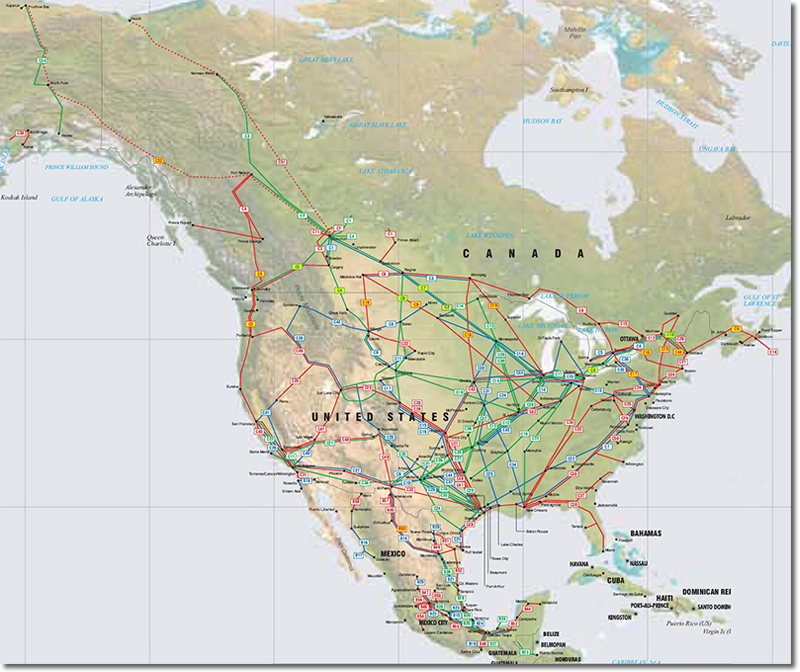

The preferred method of shipping crude oil, from a safety and cost perspective, is via pipeline. Pipeline transport also has a lower carbon footprint than shipping by rail. North America has an enormous underground network of oil and gas pipelines. In the U.S. alone there are 2.5 million miles of oil and gas pipelines - 53 times the length of the 47,000 miles in the US Interstate Highway System. Below is a partial map of just the largest pipelines that crisscross North America.

Major North American Oil, Gas, and Product Pipelines

Source: Theodora

It’s usually a bit cheaper to ship by pipeline. A 2013 investor presentation from the oil refiner Valero indicated that the company can ship Bakken crude by rail to the West Cost for $9/bbl, to the East Coast for $15/bbl, or to the Gulf Coast for $12/bbl. Pipeline routes are not available from the Bakken to all of those destinations (although the pipeline infrastructure is being expanded), but a rough approximation is that shipping by pipeline is ~$5/bbl cheaper than shipping by rail. The shipping distance is obviously a factor, but the point is that shipping by rail is not prohibitively expensive compared to pipelines.

Over the past few years as oil production continued to expand in places like the Bakken, there was downward pressure on oil prices. Meanwhile, global crude oil demand continued to grow, and crude oil production outside the U.S. was relatively flat. While U.S. crude oil production rose by 3.2 million bpd between 2008 and 2013, global production outside the U.S. only rose by 0.5 million bpd during that time. As a result, there was upward pressure on the price of crude oil that could be sold internationally, and downward pressure on crude oil in the continental U.S. This opened up a price differential that provided an incentive to ship Bakken crude to the coasts. As a result, shipments by rail skyrocketed:

There are a number of studies that show that shipping by rail is more dangerous than shipping by pipeline. In fact, a year ago the U.S. State Department did an analysis that projected that if oil is shipped via the (politically-delayed) Keystone XL pipeline, there will be 6 fewer deaths per year than if that same oil is shipped by rail. The environmental activists who work to block pipelines will dispute this, because they believe that blocking pipelines is an effective way to slow down the development of crude oil reserves. Their argument would be “There won’t be 6 additional deaths per year, because that oil will not take the rail instead.” I think this is a naive view, and is contradicted by actual observations.

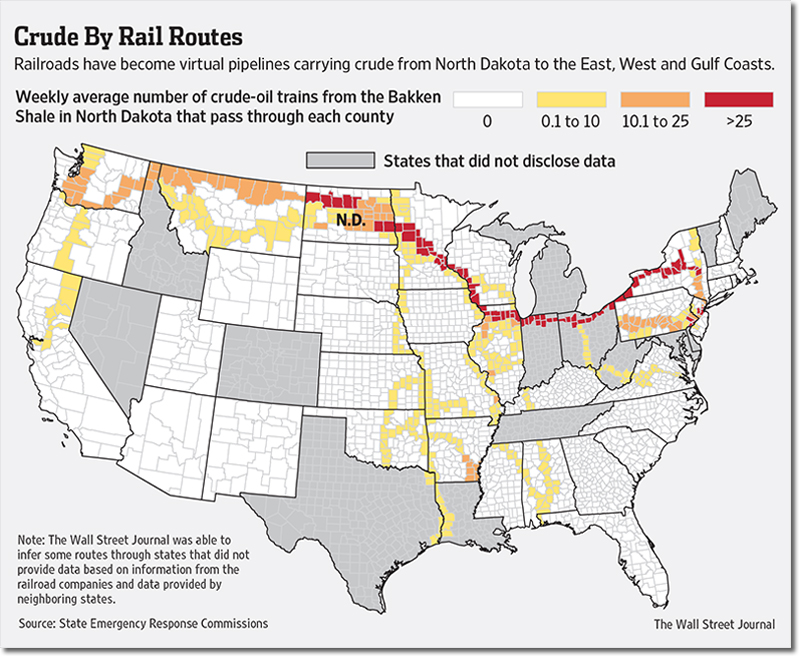

So, where is all of the new oil-by-rail traffic? The Wall Street Journal published a nice graphic detailing these routes:

The greatest increase in traffic has come from that Bakken to East Coast “virtual pipeline.” Warren Buffet’s BNSF Railroad, incidentally, is the biggest player in moving oil out of the Bakken region. The red line in the map above likely represents the highest risk for future accidents given the number of crude oil trains traversing that route. In my view the only things that will slow the oil-by-rail trend are if either

1. The price of oil drops so low that it makes development uneconomical; or

2. The price differential between the source and the destination vanishes.

These are issues related to demand. If demand is there, the oil will flow. Just look at the war on drugs to gauge the effectiveness of trying to cut off supplies in the fact of strong demand.

But back to the question of why we ship oil by rail. The reason is that consumers demand oil, and that drives the price higher. Where consumers are willing to pay, the oil is going to get to market one way or the other. In this case, insufficient pipeline infrastructure out of the Bakken is the major driver of the oil to rail development, but blocking pipelines will have the same effect as long as the demand is there.

Everyone who uses oil is culpable to some extent for these sorts of incidents. People will shake their heads at this latest incident, but few will change their driving habits to use less oil. Until that happens on a large scale, the oil will keep moving, perhaps right through your home town.

Source: Energy Trends Insider

Related: The Best Way to Transport Petroleum - Trucks, Trains, or Pipelines?