The Difference between Procurement & Supply Chain Management and Why the Two Should Converge

Many companies globally have kept the procurement and supply chain functions independent of each other, consequently, they have not been able to leverage the efficiency of merging the two.

Procurement and Supply Chain

- Procurement and supply chain teams should respond quickly to challenges and must be resilient and dynamic in rapidly changing environments

- Organizations with a streamlined supply chain end up with 15% lower supply chain costs, hold 50% lower inventory, and produce three times faster cash-to-cash cycles than those without

- Investing in a unified supply chain and procurement software solution helps enterprises gain end-to-end visibility, reliable master data, and real-time analytics

Procurement management strategically optimizes the organizational spending while acquiring quality goods and services from a panel of approved vendors within a given budget and an established deadline.

Supply chain management (SCM) manages the activities from acquiring raw materials for production, logistics, and the delivery of finished products to the consumer who placed the order.

Organizations often fail to respond quickly to disruptions due to a lack of timely information exchange between procurement and supply chain teams.

Many companies globally have kept the procurement and supply chain functions independent of each other. Thus, they have not been able to leverage the efficiency of merging the two.

However, global disruptions like the shortage of materials, pandemics, war, trade barriers, lack of skilled workforce, and unrealistic expectations of customers brought up in an era of instant gratification and flagging economies have added immense pressure on the supply chains to an already complex activity.

You can further imagine an organization having each department operating as silos toward its mission and goals in delivering value to all stakeholders and failing miserably at the enterprise level.

Why does this happen?

Because, even though each of these entities increased efficiency at the regional level, there was no exchange of timely information or communication between these disparate entities, inevitably, failing to respond quickly to disruptions, leading to the disarray of supply chains.

In such a scenario, would it make sense to unify procurement and supply chain activities under a single head and deploy a unified procurement and supply chain software?

Here’s a quick review of the definitions of these terms, and an understanding of their importance in an organization.

What is Procurement?

Procurement management strategically optimizes the organizational spending while acquiring quality goods and services from a panel of approved vendors within a given budget and an established deadline.

Sourcing, requisitioning, ordering, quality checks, vendor payments, and reconciliation form part of the procurement function.

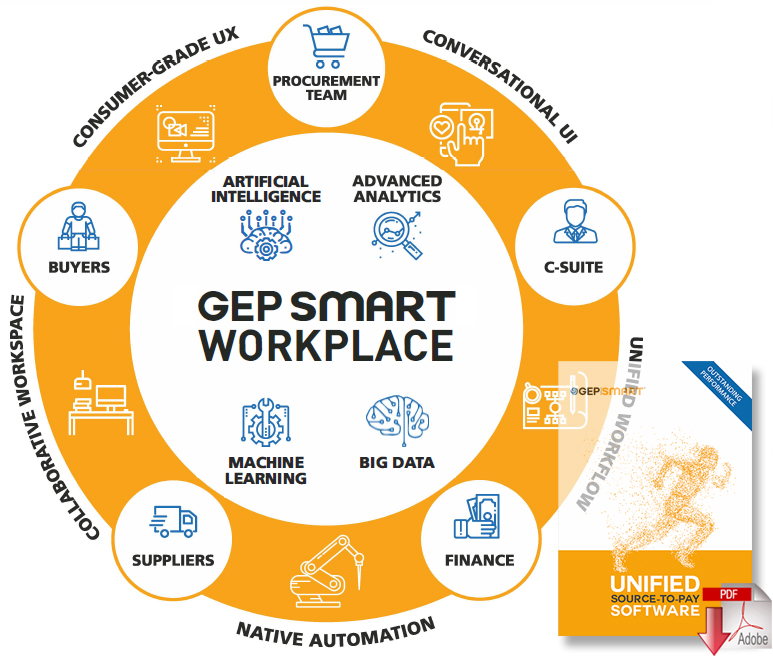

In addition, businesses desiring control and better visibility are already investing in cutting-edge procurement software. Automation too has become vital for procurement organizations to be more effective and efficient in achieving higher growth.

An intelligent procurement software offers a seamless source-to-pay platform that provides a great user experience and effortlessly integrates into the existing business.

Strategic procurement management directly impacts an organization’s revenue and business operations.

Moreover, it adopts a digital transformation by investing in a unified source-to-pay platform built on AI and advanced process automation.

Also Read: Procurement Is Turning Autonomous

A unified source-to-pay means the software allows you to identify opportunities helps you to save on costs, negotiate contracts, raise purchase orders, manage vendor relationships and pay invoices all under one platform.

What is Supply Chain Management?

Supply chain management (SCM) manages the activities from acquiring raw materials for production, logistics, and the delivery of finished products to the consumer who placed the order.

Additional Read: Types and Stages of Supply Chain Management

It spans all logistics movements, inventory control of both raw materials and finished products, and ensures the finished goods reach the end-user safely and on time.

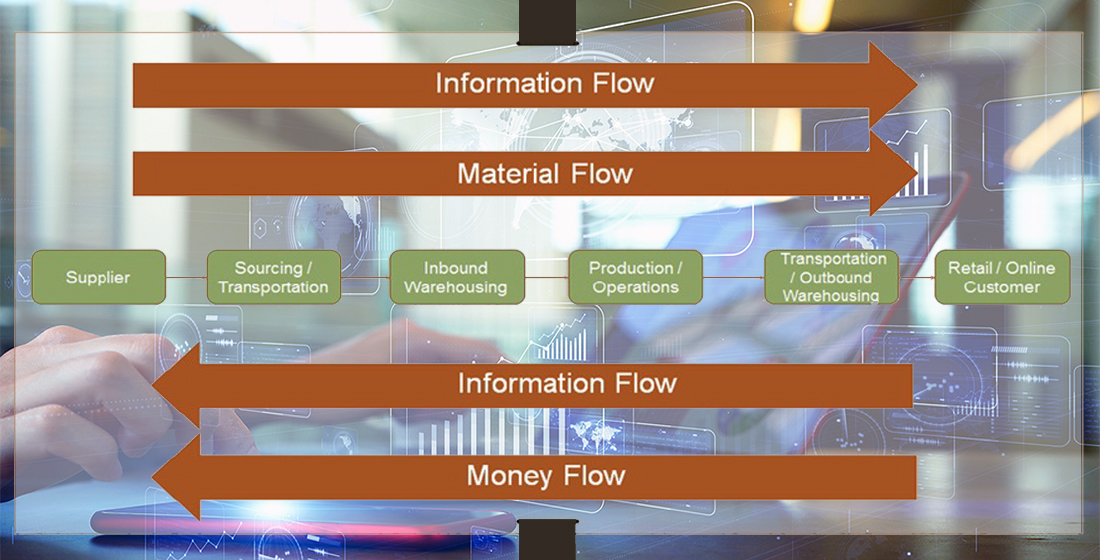

Moreover, the supply chain also involves the flow of materials and information in both upward and downward directions, as depicted in the Supply Chain Management Flow below.

Supply Chain Management Flow

Today’s supply chains should respond quickly to challenges and must be resilient and dynamic in rapidly changing environments. These unforeseen changes in the form of natural disasters, political instability, trade barriers, and inflation are impossible to get a handle on unless the SCM process is digitalized and part of it automated.

The cloud-based unified supply chain software solution integrates effortlessly with the legacy systems of your business and offers unparalleled visibility to every feature of a global complex supply chain. In addition to the standard attributes, advanced supply chain software provides predictive analytics, cognitive capabilities, data normalization, and decision support tools, ensuring your business is ahead of the competition.

What are the Differences Between Procurement and Supply Chain Management?

Procurement focuses on optimizing expenditure on the inputs for the production, and supply chain focuses on optimizing the supply chain for delivering value and finished goods.

Procurement oversees goods and services acquisition for production, whereas the supply chain is also responsible for production and distribution.

Also, procurement falls under the ambit of supply chain management.

Procurement and Supply Chain Convergence - The Way Forward

A study among procurement and supply chain professionals from a broad spectrum of industries was carried out by GEP in partnership with the Supply Chain Resource Cooperative at North Carolina State University (NCSU)

According to this study, nearly 59% of surveyed professionals stated that the procurement and supply chain gap is a major concern of the nine issues examined.

Even though differences exist in how one views procurement and supply chain management, as different entities or that procurement is a part under the more extensive umbrella of supply chain management, it is clear that a dynamic collaboration between the two is vital for the success of an organization.

Furthermore, organizations with a streamlined supply chain end up with 15% lower supply chain costs, hold 50% lower inventory, and three times faster cash-to-cash cycles than organizations without a streamlined supply chain. It is also recorded that 79% of businesses with efficient supply chains have higher revenue growth than the average business in their respective industries.

The benefits of collaboration and convergence between the two functions accrued by the organization are better risk evaluation and mitigation, increasing customer satisfaction, and retention, optimizing spend, providing an agile and resilient supply chain, and improving supplier/vendor relationships.

Collaboration between the two entities also helps an organization plan much ahead to deal with supply chain disruptions, help in demand forecasting, align supply accordingly and reduce inventory.

In conclusion, investing in a unified supply chain and procurement software solution helps enterprises align their business priorities to meet their customers’ and stakeholders’ expectations through end-to-end visibility, connected processes, reliable master data, and real-time data and analytics.

Webinar: Why Supply Chain Convergence Matters

It’s no secret that data is critical for accurate decision-making, and organizations have it in abundance. However, having it is only half the battle. Consolidating data from different parts of the organization as well as from suppliers, customers and producers require breaking down silos, and that’s easier said than done.

A convergence strategy is bold and far-reaching, and the potential upside is immense. However, who takes the lead, and what steps can you take to enhance procurement and supply chain convergence?

Watch the webcast Why Supply Chain Convergence Matters, sponsored by GEP and Microsoft, for the answers. Matthew Pedersen, VP-Consulting, GEP, and John Kovac, Director of Manufacturing - Industry Solutions Group at Microsoft, provide expert insight into why consolidating disparate sources of data to produce a single source of truth can have profound effects on innovation, cost reduction, and efficiency.

Key Discussion Points

- The initial steps you can take to break down supply chain silos

- The advantages of consolidating data into one source, and the challenges that may arise

- How Microsoft executed a successful supply chain convergence strategy

Related Resources

The Forrester Wave™: Supplier Value Management Platforms, Q1 2022

In this Forrester Wave™ report, we take a deep dive into a 31-criterion evaluation of supplier value management platforms, we identified the nine most significant ones - Coupa, GEP, Ivalua, JAGGAER, Oracle, SAP Ariba, Workday, Xeeva, and Zycus - and researched, analyzed, and scored them. Download Now!

Supply Chain Convergence in a Disruptive Environment

This paper is a must-read for supply chain and procurement leaders who are looking to fortify their supply chains with greater resilience to disruption. Download Now!

GEP Outlook 2022 - Supply Chain & Procurement: Key Trends, Challenges, and Opportunities

Get actionable insights to effectively deal with disruption and uncertainty and learn supply chain and procurement strategies that can help your business thrive in the new normal. Download Now!

Transforming Supply Chains for Higher Performance and Resiliency

This study from Harvard Business Review Analytic Services commissioned by GEP explores the digital status quo of supply chains today, and how enterprises can and must revamp their supply chains to thrive in a never-normal world. Download Now!

More Resources from GEP

Related Article: Top 5 Supply Chain Processes That Need Better Collaboration

Article Topics

GEP News & Resources

GEP Procurement & Supply Chain Tech Trends Report 2024 How Procurment and Supply Chain Leaders Should Handle Supply Chain Disruptions Optimizing Business Outcomes by Investing in Sustainable Supply Chains and Procurement Optimizing Direct Material Sourcing with a Unified, Extensible Source-to-Pay Platform Generative AI in Procurement Navigating the Cost-Plus World of Supply Chains How to Avoid the Pittfalls of Contract Management in Telecom and High-Tech More GEPLatest in Supply Chain

Spotlight Startup: Cart.com Walmart and Swisslog Expand Partnership with New Texas Facility Nissan Channels Tesla With Its Latest Manufacturing Process Taking Stock of Today’s Robotics Market and What the Future Holds U.S. Manufacturing Gains Momentum After Another Strong Month Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Apple Overtaken as World’s Largest Phone Seller More Supply Chain