The 3D-Printed Athletic Shoe Race and What It Means For Your Retail Based Supply Chain

With the 120th running of the Boston Marathon, the competition to bring 3D-printed athletic shoes to the general market is sprinting ahead, but for the sneaker industry, the technology, and its supply chain, this will be a marathon, not a sprint.

On March 7, athletic apparel giant Under Armour introduced its first partially 3D-printed performance training shoe, the UA Architech, which sports a 3D-printed lattice-structure midsole.

The shoe was available for $300 in a very limited edition of 96 pairs on March 18 via the company’s website and at its flagship Brand House store in its hometown of Baltimore.

It sold out online before 7 a.m. that day.

Under Armour was founded in 1996, so the limited edition number “ties” into the company’s 20th anniversary celebration.

More significantly, however, this launch vaulted the relative newcomer to the athletic shoe category ahead of industry goliaths Nike and Adidas and well-established New Balance in the race to offer a 3D-printed athletic shoe to the general consumer market.

Here’s what you should know.

The UA Architech

Under Armour decided to release a 3D-printed all-purpose training shoe in part because its competitors are working on 3D-printed running shoes and in part because the company’s roots are in training, Under Armour vice president of outdoor and training footwear Chris Lindgren told SI.com.

The Architech is a multipurpose trainer, which means an athlete can go from an exercise such as weight training to sprinting without changing shoes. In order to accomplish this “feat,” Under Armour had to design the shoes to be stable yet lightweight, and provide significant flexibility and cushioning.

“The secret sauce is the 3D-printed lattice-structure heel, which is produced from a combination of polymers and elastomers that “makes it soft enough and strong enough to protect and provide structure, but with cushioning underfoot”

Under Armour has reportedly been working on the Architech for two years. The process involved studying various different geometric shapes and structures in nature and architecture - hence, the shoes’ name - to develop a midsole design best suited for a quality multipurpose trainer.

Notably, Autodesk’s Within software was used to generatively design the lattice midsole, which required 3D printing to produce, as it couldn’t be made using traditional manufacturing techniques. Generative design is an emerging technology where a computer algorithm creates structures based on criteria like durability, flexibility, and weight. Autodesk Fusion 360 software was also used in the shoe’s development.

Under Armour reportedly worked with more than 80 athletes who tested and provided feedback on the countless iterations of the trainer, which were tested for more than 120 hours both by athletes and in the company’s lab. The rapid prototyping involved was enabled by 3D printing.

Under Armour reportedly plans to release several other 3D-printed shoe models this year.

Under Armour dashed past New Balance for this win.

What 3D Printing Means for Your Supply Chain

by Pete Basiliere

A broader understanding of 3D printing’s value to the supply chain is increasing investment plans across industries worldwide. Gartner research found that 65% of supply chain professionals are using or will invest in 3D printing over the next 2 years as they recognize its ability to produce product and augment manufacturing operations.

The first 3D printing technology was invented 30 years ago. Over time more uses of 3D printing throughout the supply chain have been developed, especially in aerospace, healthcare and general industrial manufacturing. For example, 3D-printed personalized medical devices - hearing aids, dental implants and braces, and prosthetic limbs - are more common than many people realize. Recent advances in hardware, software and materials are making 3D printing a more viable process across the supply chain even as its adoption remains low.

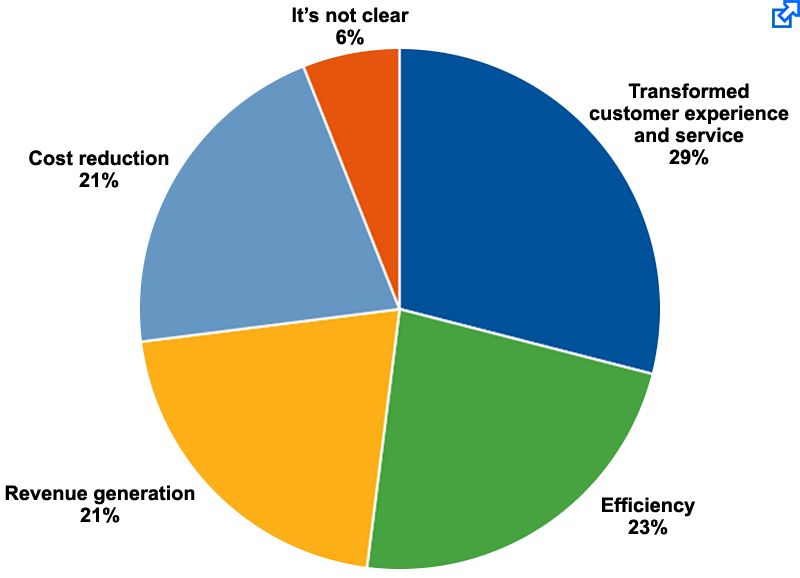

My colleague Mike Burkett and I recently published a report that focused on the impact of trends identified in a global Gartner study of 248 supply chain professionals from across industries. We found widespread acceptance of 3D printing which is having a near-term impact on supply chains. And while supply chain professionals certainly value 3D printing as a way to reduce costs and optimize current processes, most value 3D printing as a means for providing more choice to their customers.

Supply Chain View of the Primary Value of 3D Printing

Source: Gartner (March 2016)

We also found that 65% of supply chain professionals are using or will invest in 3D printing over the next two years as they discover an innovative approach to produce product and augment manufacturing operations. Evidence of this widespread adoption is reflected in the survey when we asked these supply chain professionals to indicate their supply chain organization’s investment status or intentions. Regarding 3D printing technology specifically, the respondents indicated that they:

- Are currently using or piloting 3D printing: 26%

- Plan to invest in 3D printing within 2 years: 39%

- Plan to invest in 3D printing within 2 to 5 years: 25%

- No plans to invest in 3D printing within the next 5 years: 10%

These results were fairly consistent across consumer, industrial, and healthcare value chains that we surveyed.

3D printing can reduce cost and improve efficiency but it is rarely used to replace an automated process that is generating product at high volume. More often 3D printing is used to enhance the customer experience by producing unique product or augmenting manufacturing tooling. The bottom line margin impact of 3D printing on the supply chain comes in part from delivering this agility and flexibility more cost-effectively and within a reduced lead-time versus traditional manufacturing methods such as machining, injection molding and casting.

Nevertheless, 3D printing is not a fit for all parts or assemblies produced throughout the supply chain today. 3D printing’s potential must be balanced against its constraints. Our list of important considerations includes these three:

- Each of 3D printing’s seven technologies have unique capabilities so the technology and therefore the choice of 3D printer is determined by the intended use of the items that will be produced.

- 3D printing is limited to a narrow range of plastic, ceramic, biological and metal materials compared to traditional manufacturing processes. While the supplies of printable materials are sufficient, the narrow range restricts the types of products that can be 3D printed and sourcing options.

- 3D printing’s total process cycle time (including preparations and post-processing) and process variability (for example, repeatable quality to specifications) versus existing methods (such as injection molding) must be evaluated.

What does this mean for you? We recommend that at the very least you gather a cross-disciplinary team to evaluate both opportunities and risks to the supply chain while extending 3D printing beyond design and prototyping to custom tooling and finished goods.

Register & Download: What 3D Printing Means for Your Supply Chain

New Balance

New Balance’s 3D-printed running shoe will launch in April in Boston.

The Architech’s release means that Under Armour sprinted ahead of New Balance to become the first company to offer a 3D-printed athletic shoe to the general consumer market. Privately held, Boston-based New Balance announced in November that it plans to launch a limited edition 3D-printed running shoe in Boston this April - no doubt to coincide with the Boston Marathon today, April 18, 2016 - and then in select New Balance retail locations around the world.

The two titans in the athletic shoe business, Oregon-based Nike and Germany’s Adidas, are currently no-shows in this competition. However, both announced last October plans to step-up their use of 3D printing to include producing customized athletic shoes for the general consumer market.

Adidas unveiled Futurecraft 3D, its concept for a running shoe with a 3D-printed midsole customized to provide the right fit and cushioning for a specific consumer’s foot. Nike’s announcement at its investor day event didn’t provide any details. Both companies have used the innovative technology to make extremely limited edition, customized spikes for athletic shoes for elite athletes.

Customization: The Olympics for 3D-Printed Shoes

The future of the UA Architech and other 3D-printed athletic shoes? Customization.

Under Armour’s win in the race to become the first company to sell 3D-printed athletic shoes to the general public is impressive; one would have thought that the industry biggies would have moved a little faster to secure this victory. It’s great PR, and first-mover advantages can be lasting. (New Balance, however, will become in April the first company to sell a 3D-printed running shoe to the general consumer market, unless one of its competitors makes a last-minute plunge for the finish line.)

The much bigger prize in terms of revenue and profit, however, lies ahead with customized 3D-printed athletic shoes. This product category should explode in size as 3D-printing technology further advances. It seems probable that within just a couple of years, consumers will be able to go into select athletic shoe companies’ retail stores to have their feet digitally (excuse the pun) scanned or will do the scanning in the comfort of their homes.

In the latter scenario, they’ll upload the scan and other relevant information with their order. The shoes will then be 3D-printed, perhaps by a partner company, and shipped to the customer.

Such customized shoes will surely be priced at a premium, allowing for a greater profit margin (at least eventually) for athletic shoe companies. Investors looking to profit from this trend could consider investing in Nike, Adidas, and Under Armour.

Shares of the former two have raced to total returns of nearly 30% and 53%, respectively, for the one-year period ending March 18, leaving the S&P 500’s flat performance in the dust. Under Armour has returned 4% over the same period, though it’s the longer-term winner, with a five-year return of 433% that considerably outpaced Nike’s 264% and Adidas’s 101% returns.

Source: The Motley Fool

Search SC24/7 for all “3D Printing”

Article Topics

Autodesk News & Resources

The 3D-Printed Athletic Shoe Race and What It Means For Your Retail Based Supply Chain Autodesk and Netsuite Partner to Transform Manufacturing in the CloudLatest in Supply Chain

TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Nissan Channels Tesla With Its Latest Manufacturing Process Taking Stock of Today’s Robotics Market and What the Future Holds U.S. Manufacturing Gains Momentum After Another Strong Month More Supply Chain