Study Highlights Digitalization of U.S. Manufacturers

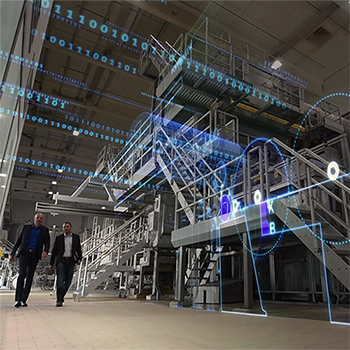

Manufacturers large and small are aware that digitalization continues to drive every industry forward, making the American landscape increasingly competitive, and digital solutions are essential in every industry today.

A recent research study of more than 200 manufacturing executives conducted by London-based Longitude Research, on behalf of Siemens, has been released, revealing two distinct categories for U.S. manufacturers along the path to adopting digitalization – “the efficiency experts” and the “revenue re-inventors.”

As part of the study, manufacturers are able compare their own digitalization status amongst their industry peers through a benchmark online survey.

The study evaluates manufacturers’ digital capabilities across core dimensions using their relative progress to provide an overall score.

Capabilities measured included data intensity, connectivity, adaptability, integration, security and people.

As part of the project, a comprehensive set of soon-to-be-released mini-reports were developed based upon several key sectors, including aerospace, automotive, chemicals, food and beverage and energy.

According to the report, rather than one single technology, though, digital is diffuse - spanning data and analytics, cloud computing, the Internet of Things and more.

“Efficiency experts” are noted as pushing hard and fast on digital technologies such as connected sensors, virtual training and artificial intelligence, with the motivation of embracing this approach being to increase uptime and efficiency and to keep their employees safe - in essence, to do what they do, but faster and cheaper.

By contrast, “revenue re-inventors” identify themselves as both financially and digitally ahead of their peers, and find motivation for digitalization in opening up new markets and reinventing themselves and what they sell.

“It’s probably not surprising to see mid-sized companies delay in embracing new technologies, but even Fortune 500 companies sometimes hesitate based on various barriers,” as quoted by Raj Batra, President, Siemens Digital Factory Division, U.S. in the report.

“Companies are aware that digitalization is driving industry forward and that it is essential in long-term strategy and planning to remain competitive in a global economy. Innovation and technology is available today that will enable a digital path to success.”

Some key highlights:

- U.S. manufactures are facing significant data gap

- Companies need to develop and articulate a top-down digitalization strategy

- Lack of industry-wide standards for key technologies hinders digital progress

- Real-time study allows users to compare their digitalization path against others

- The top five digital technologies implemented by manufacturers include cloud computing at 85%, connected sensors in plants at 65%, connected sensors in products at 59%, 3D printing at 39% and advanced data analytics tools at 34%

- 76% of efficiency experts and 98% of revenue re-inventors stated that they use predictive analytics to forecast performance of production equipment or processes in most or all parts of their organization

- Only one-fifth of the respondents stated that they analyze more than 60% of the production data they collect, meaning a significant amount of data goes unanalyzed

- 38% admit that the analysis gap of production data is three days or greater

The Top Five Digital Technologies Implemented By Manufacturers

Article Topics

Siemens News & Resources

Siemens, Universal Robots, and Zivid partner to unveil smart robotic picking solution Power Transmission: From horseback to rocket ship Mecalux launches an AI-driven robotic order picking system with Siemens’ technology A new look for motors, gearboxes and gears New executive management board at Siemens Logistics ABB to acquire Siemens low voltage NEMA motor business Siemens introduces Sinamics G115D More SiemensLatest in Business

Ranking the Top 20 Women in Supply Chain TIm Cook Says Apple Plans to Increase Investments in Vietnam Amazon Logistics’ Growth Shakes Up Shipping Industry in 2023 Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Nissan Channels Tesla With Its Latest Manufacturing Process U.S. Manufacturing Gains Momentum After Another Strong Month More Business