Social Networking Comes to Transportation Management via Cloud-Enabled “Control Towers”

Cloud-enabled transportation “control towers” are transforming logistics and supply chain performance. Shippers can realize benefits from true end-to-end supply chain integration that can be operated through an optimized transportation service network.

There’s increasingly more noise and dust around the strategic virtue of the “transportation control tower” concept.

It’s not all that new; in fact, back in the last century we talked about similar capabilities, calling them by a different name: load control center, command center, and the network service center.

The one thing these various monikers shared in common was an aspiration to provide an element of discipline, as well as common and standardized business processes across the enterprise (or big chunks of it, such as divisions, regions, or continents), driven by leading industry practices and enabled by technology.

And one of the key functions that has been consistently hungered for over most of the last decade and been simultaneously elusive is the capability for true end-to-end supply chain visibility.

Why is there such a growing groundswell of interest around the control tower concept and visibility now? A few key things come into play:

- Companies that only gave a passing nod to managing supply chain performance in the past have had epiphanies and now recognize that supply chain management is a critical strategic weapon in top-line revenue growth, cost containment customer satisfaction, and repeat business.

- Cloud-based enabling technology has radically changed the game for those bold enough to “go where no man has gone before.”

- Globalization and coping with what many perceive to be a state of permanent volatility are forcing companies to “never settle” and continually innovate within their supply chain operations.

The notion of a command center or transportation control tower, while of great interest to many organizations, was hamstrung by technological limitations.

For those who remember the early 1990s, it was then that a product was launched that sought to provide end-to-end visibility across the supply chain. It was leading-edge at the time, even contemplating parallel supply chain functions (e.g., physical movement of product along with simultaneous movement of the related documents).

The problem many shippers encountered with this product, and other similar ones, was the difficulty in creating a comprehensive network of connected trading partners. In many instances, it was a one-to-many relationship where the “many” sometimes numbered in the thousands.

In the days before the Internet, quite a bit of time and expense was involved in connecting with existing and new trading partners.

The rise of the Internet eased the burden of simultaneous global communications for many. But in many instances, the trading partners were small, unsophisticated providers who had trouble adopting the Internet as a business tool.

The predictable end result was incomplete data, which left holes in the supply chain visibility pipeline. The equally predictable result was that people didn’t trust incomplete and inaccurate data, so usage dropped away and visibility projects were declared a failure. While this is a generalization, it largely holds true for many networks.

The net effect was that command center operations focused on what they could do, which was largely domestic and often a niche play, rather than enterprise-wide, end-to-end supply chain management where this sort of capability is needed most. Examples are centers that managed rolling assets, such as rail car and private truck fleets, or load control centers that managed domestic truckload business.

Building the tower

True, end-to-end, global supply chain visibility remained elusive, although if you read through back issues of Logistics Management you will see that for most of the last decade supply chain visibility and event management has topped the list of “must haves” for logistics professionals.

So what’s the answer? We put forth several possibilities: Our view is that the transportation control tower concept can provide tangible strategic benefit. But how do we operationalize it? There isn’t a silver bullet just yet where you can go to an app store and download a plug-and-play app—but we are getting close.

A possible starting point for shippers, large and small, is to assess the current state of their supply chain management capabilities objectively and with a clear eye. This is sometimes done through the aegis of a neutral third party, but it needn’t be.

The trick is mapping out what the supply chain looks like now, the capabilities that exist to manage it, and how it performs. You can then put that up against what the “should case” is for supply chain performance and what it will take to get there. The gaps will always leap out and become visible.

A next step is to examine what it takes to close those gaps. The age of making everything yourself may have passed. A smart play is to sort out what makes sense to do in-house and what makes sense to find an alternative, more efficient path to follow, employing the best enabling decision-support technology and the most skilled resources.

What’s so different about this? Let’s take a brief look back.

Perhaps the seminal game-changer was Steve Jobs. He envisioned a new world where the applications and data were device-independent. It didn’t matter whether you had a PC, an iPhone, an iPad, or any of a number of other devices. The apps and data didn’t live on the device, they lived in “the cloud.”

Next in line of seminal game-changers was Mark Zuckerberg who, with the advent of social networking, helped change the way communications between people worked. Facebook made connecting with others the work of a click.

So what’s any of this got to do with logistics management and transportation control tower concepts? First, transportation control towers function when they are fed timely, accurate information across the entire supply chain. Second, true supply chain visibility and event management works most efficiently and effectively in a many-to-many ecosystem.

It can be terribly difficult, time consuming, and expensive for every shipper to individually go out and connect with hundreds or thousands of many of the exact same service providers and vendors that everyone else is connecting to. What does make empirical good sense, however, is employing what we refer to as the “multi-tenant cloud-based solution,” which in English is Facebook for logistics.

Instead of the individual connections, companies can go out and “friend” their ocean carriers, truck lines, railroads, airlines, 3PLs, who are already on the platform. It can be faster, cheaper, and provides more timely, accurate information.

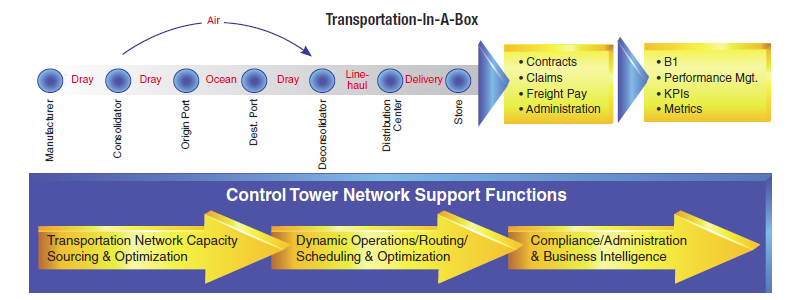

This capability, coupled with other enablers, such as cloud-based TMS solutions, as well as similar capabilities for sourcing multimodal transportation capacity, dynamically routing and scheduling shipments, auditing and paying freight charges, managing claims, and mining business intelligence to track performance and manage trends, is what really can empower the transportation control tower of the future.

There are at least three models on how to go about this, each with multiple flavors:

Transportation-in-a-Box: This is a business process outsourcing (BPO) play, where the company teams with a 3PL to hand over the operational functions of logistics and strategically manage the on-going operation, rather than a tactical approach.

Transportation Managed Service: This is a hybrid model that involves handing over logistics functions for a shorter timeframe, like an incubation period, to a third party and then transitioning it back in-house post hiring along with stabilization and training of their in-house team. For example, perhaps the organization is operationally excellent, but does not manage its sourcing functions as well as it could—or, it does that well, but is less successful at claims management and freight payment.

Advisory/Self-Service: This is where the shipper intends to keep all of the logistics functions in-house, but wants or needs third-party advisory services to help stand up the capabilities they aspire to achieve. Here are the pros and cons of each:

Transportation-in-a-Box /BPO

Pros: There is a lengthy list of positive attributes, but a compelling one is the ability to comparatively, rapidly, and economically move to cloud-based, leading-edge technology solutions, without incurring large expenditures of scarce capital dollars and enduring the sustained pain of conventional implementation.

It can also be a means to add experienced capabilities to augment the existing professional staff and hold a third party, who does this for a living, accountable for the business outcomes, possibility through a gain-share agreement.

Cons: It’s often a significant cultural shift. A common reaction is “you’re calling my baby ugly” when, in fact, the goal is to give the “baby” a different set of tools to do the job better.

Transportation Managed Service

Pros: It can be less of a culture war; it can serve as a proof of concept—it’s more like entering the pool from the shallow end and wading, at your own pace, to the deep end, rather than leaping off the high-dive.

Cons: It often sub-optimizes results and takes substantially longer to get to the end-game.

Advisory/Self-Service

Pros: For those who want to control everything internally, it can be a much more secure environment and perceived to be less risky. It can also be much less disruptive to the status quo, which isn’t always a bad thing if the operation is substantially on track.

Unbiased third parties provide two core valuable services: First, they can objectively look at the current state and bring to bear industry-leading practices from others; and second, they can often be relied on to push the envelope a bit further in transforming the business and challenging prevailing wisdom.

Cons: Third-party advisors are not inexpensive; frequently being viewed as causing interference or assumed to be demonstrating a lack of trust in the current organization to do its job. As a result, some very powerful recommendations and advice have gathered dust due to a lack of commitment to change.

Putting it in context

The pace of change is accelerating, driven by rapid advances in technology. Finding new and better ways to leverage these increasingly facile tools and capabilities is essential.

Think about the trading of securities between Europe and North America and how it was revolutionized when the laying of the transatlantic cable was completed in 1858.

The 10 days it used to take for communicating trades was reduced to minutes. We are again on the cusp of transformational change: those who can look ahead and take advantage of it will lead the pack.

The fact is that implementing the core elements of the transportation control tower, using any of the models outlined here, can deliver two major elements that rebound to the credit and vision of the activist who makes them happen.

First, supply chain performance can be significantly and demonstrably enhanced, which can also make the life of the logistics professional easier and better. And second, taking full advantage of the concepts, approach, methodology, and tools we discussed may deliver significant value in terms of benefits and cost reduction, which can affect shareholder value and help fund other initiatives.

The value of true end-to-end supply chain integration, enabled by visibility and event management that can be operationalized and operated by an optimized transportation service network, is of a magnitude that cannot be overlooked or ignored.

About the Authors: Brooks Bentz ([email protected]), Roddy Martin ([email protected]), and Bill Kammerer ([email protected]) are Managing Directors at Accenture. Tushar Narsana ([email protected]) is an Accenture Senior Manager.

Article Topics

Accenture News & Resources

What generative AI means for supply chain work Supply Chain Currents Part I: Is there a different way to move freight more effectively? Companies Shifting Away from China a Boon to U.S., Mexico Accenture survey highlights factors that can influence nearshoring decisions AI Simulation Helps Supply Chains Predict the Future Navigating Cultural, Country Differences When Nearshoring Operations Global companies are planning more regional approaches to manufacturing, selling More AccentureLatest in Technology

Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Apple Overtaken as World’s Largest Phone Seller Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs Talking Supply Chain: Procurement and the AI revolution More Technology