Simplify Automated Storage System Connectivity and Control

For operations with multiple subordinate automation systems—including automated storage and retrieval systems (AS/RS) such as vertical lift modules (VLMs), horizontal carousels and vertical carousels—connecting both their control and communications to warehouse management and material flow systems can be challenging.

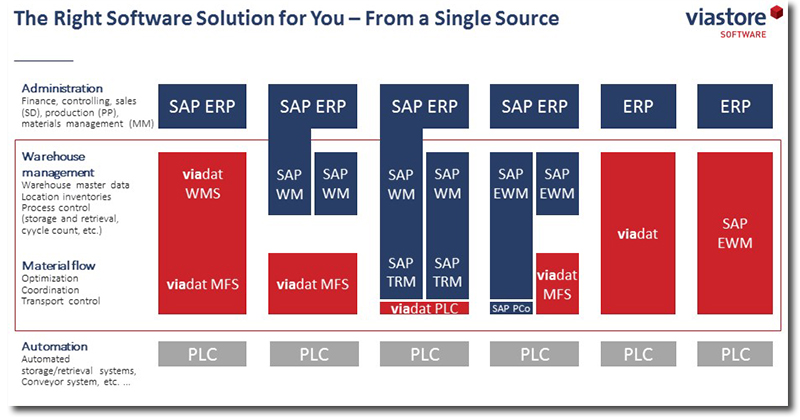

That’s why more companies are taking a closer look at implementing SAP Supply Chain Execution (SCE) Extended Warehouse Management (EWM) or SAP Enterprise Resource Planning (ERP) Warehouse Management (WM) in their automated and/or conventional warehouses.

Either choice can be customized to connect administrative functions to warehouse management to material flow to automation (and back).

Whether the choice is SAP EWM or WM, partnering with an intralogistics solutions supplier who is experienced in linking and streamlining a workflow from WMS to the given automation equipment’s programmable logic controllers (PLCs) is critical to a successful implementation and higher ongoing benefits later.

Because each integration is highly situation-dependent, and the ideal solution may require customization of standardized architecture—or application of additional software—to best achieve an operation’s goals within the constraints of budget, timeline, processes and equipment investments (both current and planned).

Depending on your use of your ERP, the connection with WMS, MFS and other software can vary.

For example, consider a new integration of an SAP ERP to a series of non-networked VLMs. Without a connection to SAP EWM or WM, goods movement in and out of the VLMs must be directed manually. That means, in order to complete a pick from the storage module, management first has to create an order for goods movement in the ERP, producing a pick list accessed by an operator at a remote computer station.

The operator receives the order information, prints it, travels to the VLM, and executes goods movement in the machine by manually keying in the instruction at the human machine interface (HMI) screen. After waiting for the proper tray to queue, the operator searches for and picks the item, and finally travels back to the computer station to confirm the pick.

The downsides to the above scenario are numerous:

-

Duplicate data capture and order management processes (both at the VLM and at the ERP interface via computer workstation).

Access to goods in the VLM can only be triggered manually.

Verification within the VLM of a correct pick, as well as acquisition of track-and-trace data (such as batch, lot, material number, serial number, etc.), is not possible.

Completed pick posting is delayed until the operator returns to the computer workstation.

- The potential for error (mispicks, posting mistakes, posting failures) is high.

Alternately, integrating the VLM’s PLCs with SAP EWM or WM saves processing, travel and pick time as well as reduces the chance of a mistake. The need for a remote computer workstation is eliminated, because the operator instead picks from an SAP dialog embedded within each VLM’s HMI.

In this scenario, the ideal integration would leverage standard connectivity architecture, configured from standard protocols—including leveraging the SAOP protocol and Hyper-Text Transfer Protocol (HTTP)—for data transfer. It would also feature:

-

Customized SAP user interface dialogs, streamlined to minimize searching and handling steps or to match specialized process flows.

Support of semi-automated inventory management, picking and data capture technologies (such as pick-to-light or radio-frequency scanning) for enhanced accuracy.

- Graphical representation of inventory and its locations on each VLM tray to support faster picking and putaway by operators.

(Note: viastore recently completed an upgrade to SAP EWM for Kaeser Compressor, one of the world’s largest manufacturers and suppliers of compressed air systems, that included new connections to the facility’s 19 VLMs.)

Download the Paper: Deploying SAP EWM or WM in Your Conventional or Automated Warehouse?

Download the Paper: viastore Speeds Up Supply Chain of Kaeser Compressors

Article Topics

viastore systems News & Resources

Updating Existing Warehouse Equipment and Software Can Mitigate Today’s Fulfillment Challenges Turning Existing Warehouses into Efficient, Optimized Fulfillment Machines Automation as a Cold Chain Labor Strategy Best Practices for a Successful Cold Storage Automation Implementation Automation: An Effective Labor Strategy in Cold Chain Warehousing and Distribution AS/RS Modernization Reduces Downtime and Saves Thousands of Dollars at Food Service Facility Automation Considerations for Frozen Product Storage More viastore systemsLatest in Warehouse|DC

Microsoft Unveils New AI Innovations For Warehouses Spotlight Startup: Cart.com is Reimagining Logistics Walmart and Swisslog Expand Partnership with New Texas Facility Taking Stock of Today’s Robotics Market and What the Future Holds U.S. Manufacturing Gains Momentum After Another Strong Month Biden Gives Samsung $6.4 Billion For Texas Semiconductor Plants Walmart Unleashes Autonomous Lift Trucks at Four High-Tech DCs More Warehouse|DC