MIT Center for Transportation & Logistics Response to the Coronavirus Crisis

It is widely expected that the year 2020 - and the new decade it heralds - is going to bring dramatic changes to global supply chains and that China will be a leading actor in this ongoing drama.

Coronavirus Outbreak

No one foresaw China’s role as the epicenter of a coronavirus outbreak that could have a crippling effect on the global economy.

The crisis could also have far-reaching consequences for China and its role in the world.

Company virus outbreak reactions taking shape

An online survey carried out by the MIT Center for Transportation & Logistics on January 28 and 29, with hundreds of respondents, shows that while some firms are largely in wait-and-see mode at this early stage of the outbreak, many are starting to map out a strategy to deal with the crisis and have initiated countermeasures.

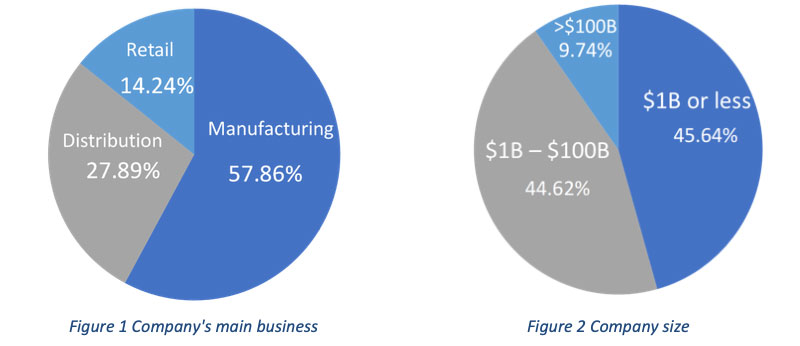

A total of 379 companies replied to the survey. Enterprises in the $1 billion to $100 billion size range represent the largest size category (39%).

16% and 14% of the companies are in the $100 million to $1 billion and $10 million to $100 million categories respectively.

In terms of their primary business, most companies are in manufacturing followed by distribution and retail (see Figures 1 and 2).

Firms were asked how they are reacting to the outbreak that originated in Wuhan, China. Sixty-one percent of respondents in the distribution and retail businesses said they are watching the news and planning a strategy.

Fewer manufacturers, Forty-one percent, are reacting in this way. However, that doesn’t mean they are doing nothing.

Forty-two percent of manufacturers are restricting travel to China, compared to 19% and 30% of distributors and retailers respectively.

There is less emphasis on consulting with local constituents and planning specific actions, with twenty percent and eighteen percent of distributors and manufacturers taking this course action.

Only nine percent of retailers report that they are pursuing such consultations.

Most of these results are depicted in Figures three and four.

Read: Is Your Global Supply Chain Prepared for the Coronavirus?

There is a broad consensus that the effect on channels to market, internal production/distribution, tier-one suppliers, tier-two and lower-tier suppliers, and current contracts and contingencies, will be zero, minor, or moderate.

A possible exception is people-related outcomes. Nineteen percent of respondents report that the outbreak will have a major effect on people.

Many airlines have curtailed their flight schedules to China. United, American, and Delta have about halved the number of flights to China while British Airways canceled all China flights. Those airlines were flying widebody aircraft with only a few dozen people aboard, making such flights uneconomic.

Expected fallout from the coronavirus in the US and beyond

In the US, a serious supply chain-related concern is that the country will run out of certain crucial products. For example, while many life-saving products are assembled and finished in the US or Europe, China is the world’s largest producer of active pharmaceutical ingredients.

Some of Apple’s Chinese suppliers are expected to extend closures beyond the Chinese New Year; Starbucks closed half of its Chinese outlets; McDonald’s and KFC announced closings; Google closed its China offices; and in a sign of light-at-the-end-of-the-tunnel attitude, US Commerce Secretary Wilbur Ross observed that the Chinese outbreak may help bring more jobs to the US.

It’s too early to draw definitive conclusions about how the coronavirus outbreak will impact global supply chains. However, the survey indicates that companies are watchful and concerned — as they should be.

At the time of writing, almost 10,000 people have been infected by the virus and it has killed more than 213 individuals while only 187 have recovered from the infection.

The World Health Organization has designated the outbreak a public health emergency of international concern. For an up-to-date dashboard of cases check here. Worryingly, the virus is spreading rapidly and there is no vaccine to combat it. Moreover, it has a two-week incubation period but there is uncertainty over how contagious people are during this time.

Hope for the best - prepare for the worst when dealing with disruption

While the situation is very serious, companies can take sensible precautions. Here are some suggestions.

- Set up an emergency management center to manage your response.

- Start planning for operating the company for maximizing free cash flow - not profits. If the crisis deepens, cash has to be preserved.

- Review your customer base; you might reach a point where it is not possible to fulfill orders for every customer. You will need to develop a customer/product priority plan.

- Maintain clear lines of communication with essential organizations such as the Centers for Disease Control in the US and the World Health Organization.

- Consult with contacts in China. Often, local people are a better source of information on what is going on in China than the media or government agencies.

Let’s hope that the crisis will turn out to be less serious than anticipated, as was the case with the SARS outbreak. But at this point, no one can afford to be complacent.

Crossroads 2020 - Understanding Uncertain Futures - April 28, 2020

The year 2020 was less than a month old when the coronavirus outbreak erupted in China. The crisis provides a stark reminder of the uncertainties that supply chains face today – and throughout the new decade. Crossroads 2020 one-day conference will explore these uncertainties, as well as measures that companies can take to prepare for them.

Related Article: How the Coronavirus is Impacting the Trucking Industry

Related White Paper

Supply Chain Lessons Learned from The Coronavirus and SARS Outbreaks

This white paper contains insights from recent interviews with leading organizations on how they are responding to the new coronavirus crisis. Download Now!

More Resources the Coronavirus Crisis

Supply Chain 24/7 Education Resource Center

Find the latest educational resources, degrees, and programs.

Visit: Supply Chain 24/7 Education Resource Center

Article Topics

MIT Center for Transportation and Logistics News & Resources

Supply Chain’s Next Decade of Dealing With the Unknown Sustainability Efforts Continue to Ramp Up, Research Finds Supply Chain Sourcing Alternatives to China DAT’s Caplice Reviews Spot Market Strategy for 2024 Budget Planning Yellow’s Demise Underscores the Need for a New Labor Relations Narrative Is Your Supply Chain Talent Ready for the Future? The Rebound Podcast: Yossi Sheffi and The Magic Conveyor Belt More MIT Center for Transportation and LogisticsLatest in Business

North Carolina Welcomes Amazon’s Newest Mega-Warehouse How Supply Chains Are Solving Severe Workplace Shortages SAP Unveils New AI-Driven Supply Chain Innovations FedEx Announces Plans to Shut Down Four Facilities Women in Supply Chain: Ann Marie Jonkman of Blue Yonder U.S. Manufacturing is Growing but Employment Not Keeping Pace The Two Most Important Factors in Last-Mile Delivery More Business